A high voltage switch operating mechanism

An operating mechanism, high-voltage switch technology, applied in the direction of contact operating mechanism, electric switch, contact driving mechanism, etc., can solve the problems of no power grid operation, no progress, design defects, etc., to save closing spring force , smaller volume, longer life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

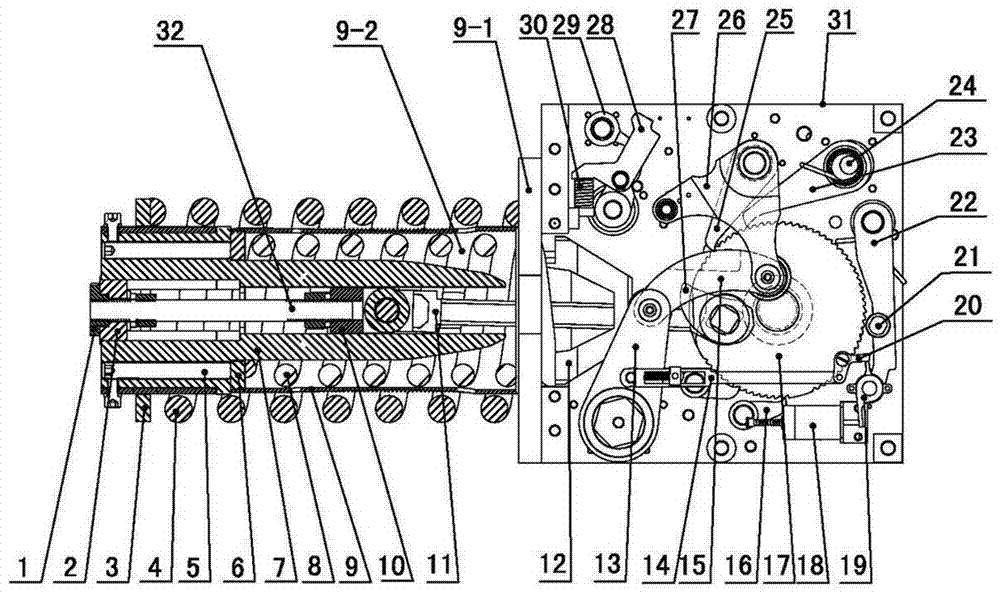

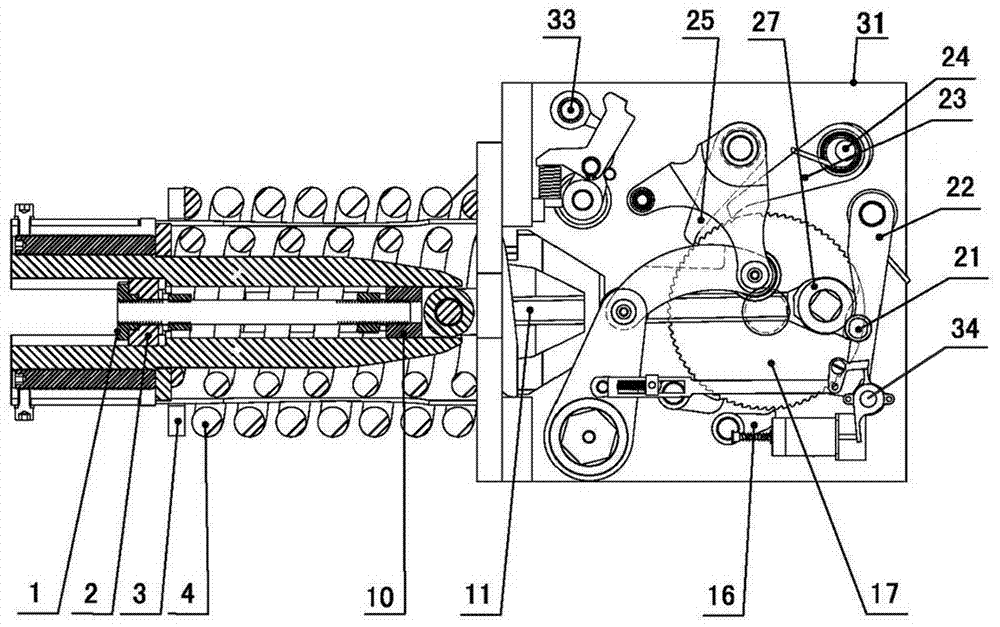

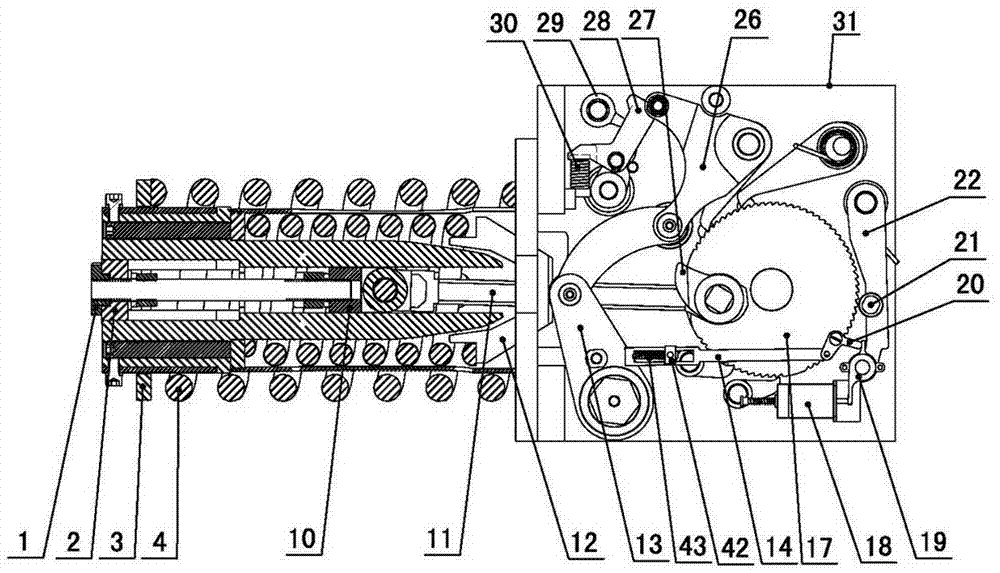

[0024] Attached below Figure 1-7 The present invention is described in detail.

[0025]The high-voltage switch operating mechanism of this embodiment includes an assembled energy storage device, a three-link device, a closing detent lock device, an opening detent lock device, an oil buffer device and a mechanical anti-jump device, and also includes a belt There is a baffle assembly 31 with an upper baffle and a lower baffle, and the baffle assembly 31 is fixedly connected to the energy storage device through a connecting plate, and the three-link device, closing detent lock device, and opening detent lock device are all fixed Between the baffle assembly 31, the oil buffer device and the mechanical anti-jump device are arranged outside the baffle assembly 31, the oil buffer device is connected with the energy storage device, and the mechanical anti-jump device is connected with the three-link.

[0026] The energy storage device comprises a motor with a first bevel gear, a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com