Electrical connector

A technology of electrical connectors and connection holes, which is applied in the field of electrical connectors and can solve problems such as loosening of the shielding layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

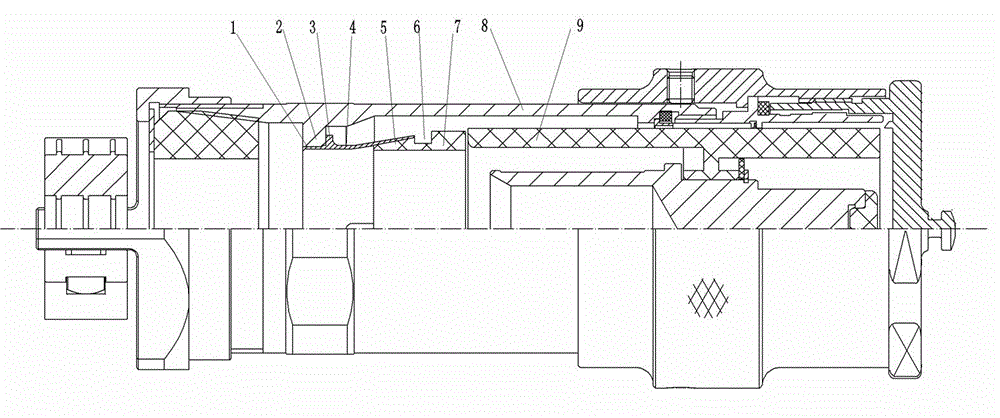

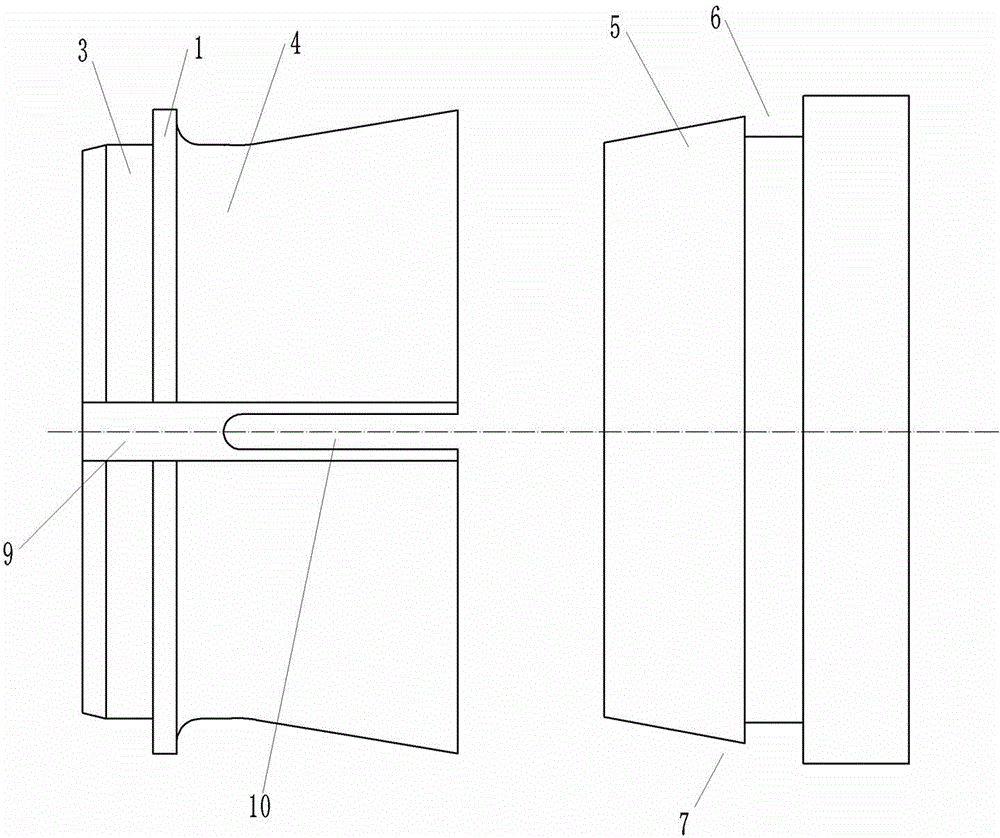

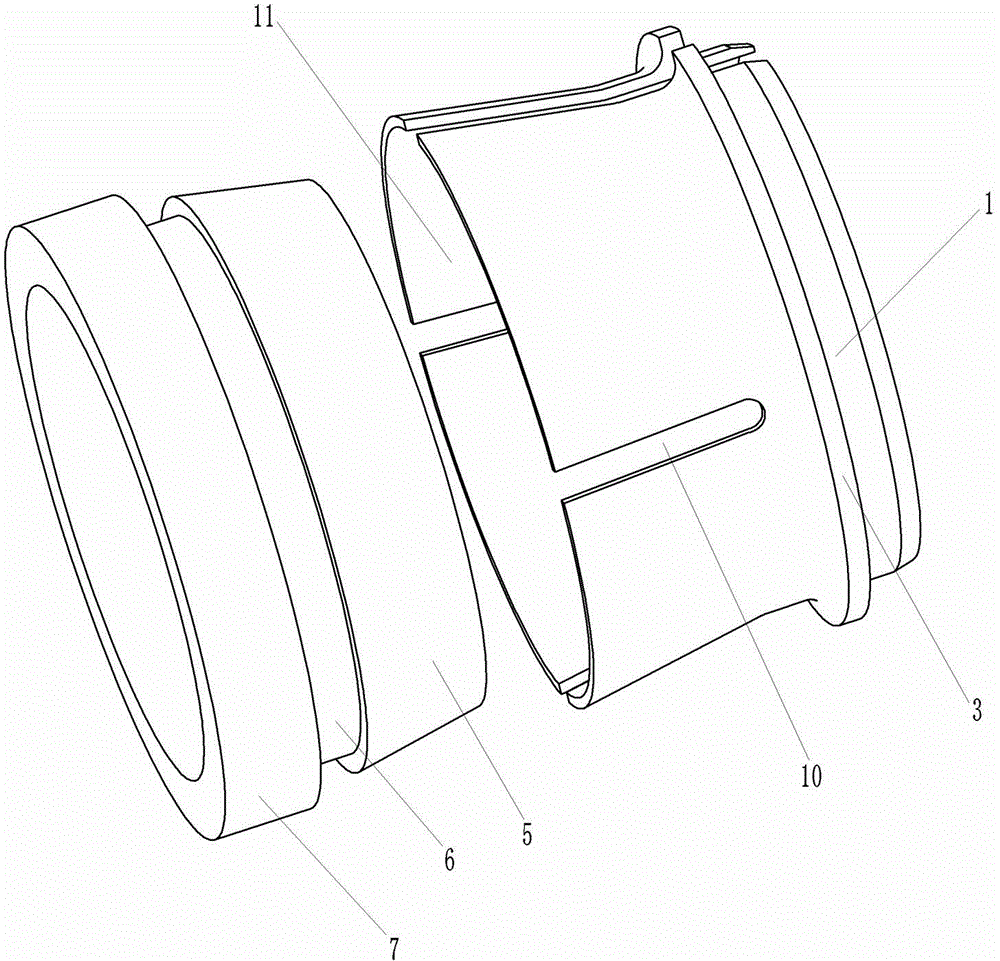

[0014] Examples of electrical connectors Figure 1~5 Shown: includes a housing 8 with a plug-in end at the front end and a shielding assembly arranged in the housing. The shielding assembly includes a shielding ring 4 and a compression ring 7. The shielding ring 4 includes an axis that is in contact with the housing and extends in the front-rear direction. The shielding ring body, the compression ring 7 includes a compression ring body whose axis extends in the front-to-back direction. The inner hole of the shielding ring body has a shielding wire connection hole section 11 at the front end, and the shielding wire connection hole section 11 gradually increases in diameter from back to front. In this embodiment, the shielding wire connection hole section 11 is tapered, and the hole wall of the shielding wire connection hole section is circumferentially spaced with three front ends extending in the front and rear directions extending to the front end of the shield ring body The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com