Low-voltage AC distribution cabinet body

A low-voltage power distribution, cabinet technology, applied in electrical components, substation/switch layout details, substation/switchgear cooling/ventilation, etc. The effect of cost, reducing the overall weight, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

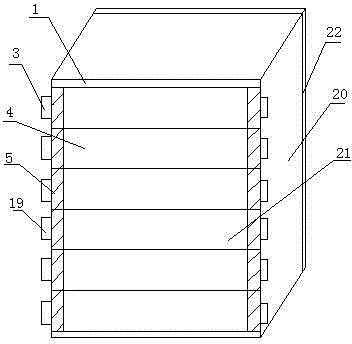

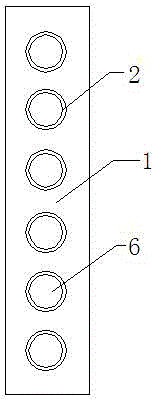

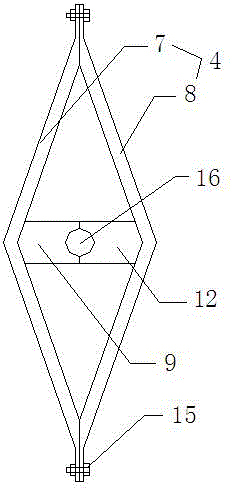

[0022] As shown in the figure, a low-voltage power distribution AC cabinet body includes a cabinet body frame 20, and a cabinet door 22 and a heat dissipation door 21 are oppositely provided on the cabinet body frame 20. The heat dissipation door 21 includes a door body 1 and a shaft sleeve 2 , the blade shaft 3, the blade 4 and the fixed casing 5, the door body 1 is a rectangular frame structure, and the two sides of the door body 1 are evenly provided with 6 fixing holes 6, and the shaft sleeve 2 is fixed on the Inside the fixing hole 6; the blade 4 includes a first blade 7 and a second blade 8, the first blade 7 and the second blade 8 are rectangular profiles bent outward from the center, and the first blade 7 The cross-sectional shape of the second blade 8 is an isosceles triangle, and a first support member 9 is provided at the bend of the first blade 7. The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com