Transformer station secondary cable laying and cleaning protective device

A secondary cable and protection device technology, which is applied to cable laying equipment, cleaning methods and tools, cleaning methods using tools, etc., can solve the problem of paint wear on the surface of substation protection screen cabinets, loss of outer insulation of secondary cables, work Complex on-site environment and other issues, to achieve the effect of benefiting the overall project quality, low cost, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

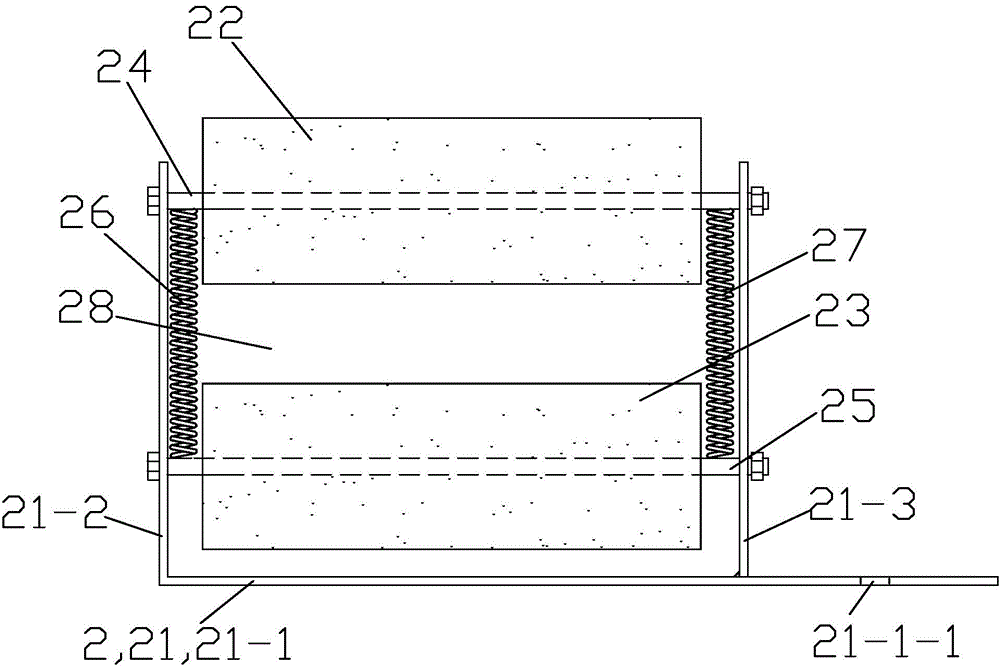

[0045] See Figure 1 to Figure 7 , The substation secondary cable laying cleaning and protection device of this embodiment is mainly composed of a mounting frame 1, a clamping cleaner 2 and a combined connector 3.

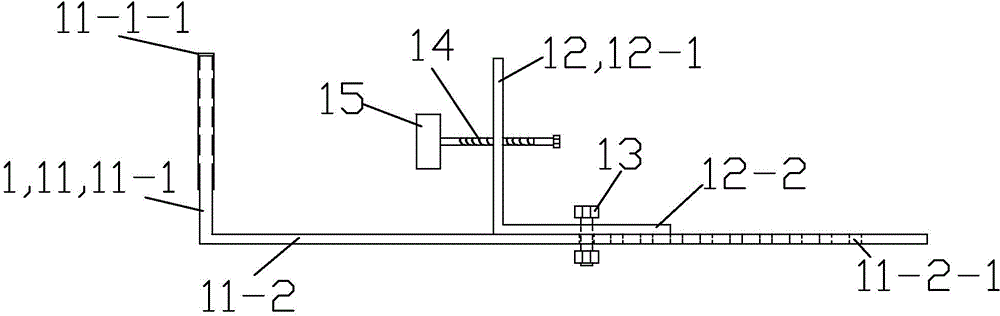

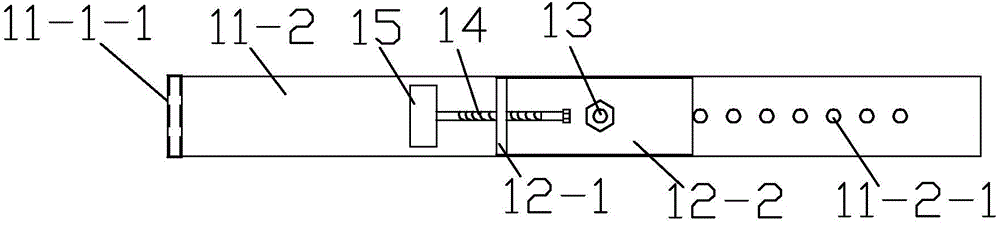

[0046] see figure 1 with figure 2 , The mounting frame 1 is mainly composed of a body 11 , a connector 12 , a connecting bolt 13 , a clamping screw 14 and a clamping block 15 .

[0047] The body 11 of the installation frame 1 is an integral part made of galvanized flat iron material. The body 11 is composed of a vertical plate 11-1 and a horizontal plate 11-2 connected vertically; both the vertical plate 11-1 and the horizontal plate 11-2 are elongated plate parts. The middle right part of the horizontal plate 11-2 is provided with a group of connecting screw holes 11-2-1 which penetrate up and down. Preferably, in order to reduce the damage to the wall corner 4 and other related parts when the mounting frame 1 is used, a rubber sleeve 11-1-1 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com