Multi-channel ultrasonic acoustic camera for mechanical state monitoring

An ultrasonic and mechanical technology, which is applied in the field of ultrasonic acoustic cameras for mechanical state diagnosis, and can solve the problems of no products for ultrasonic acoustic cameras.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

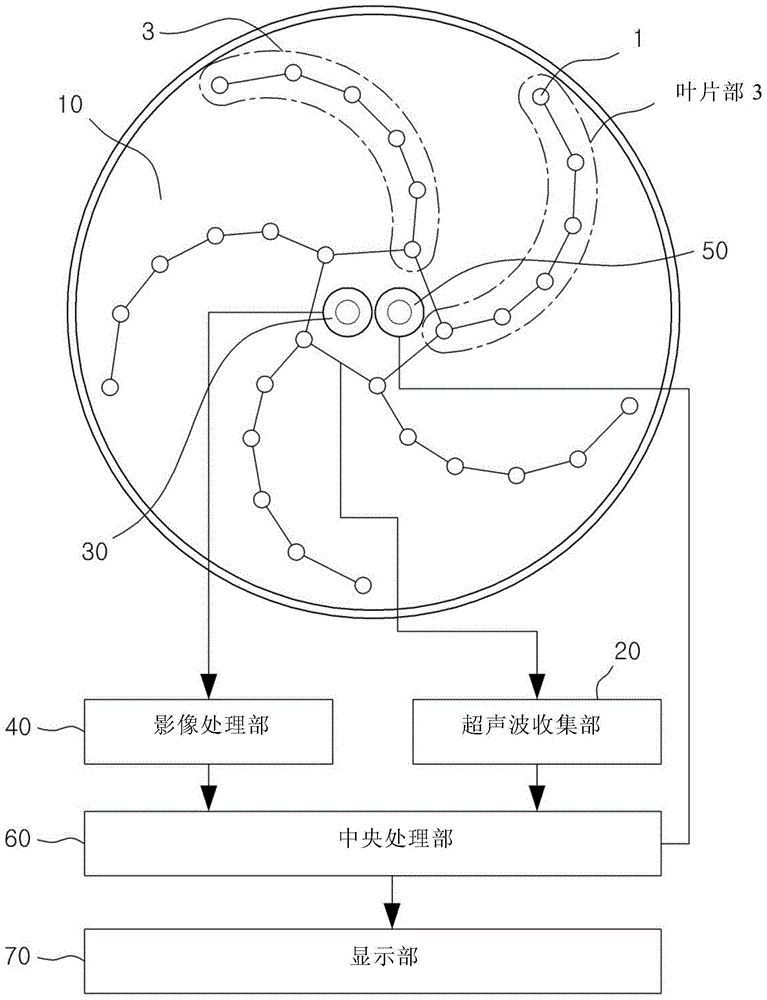

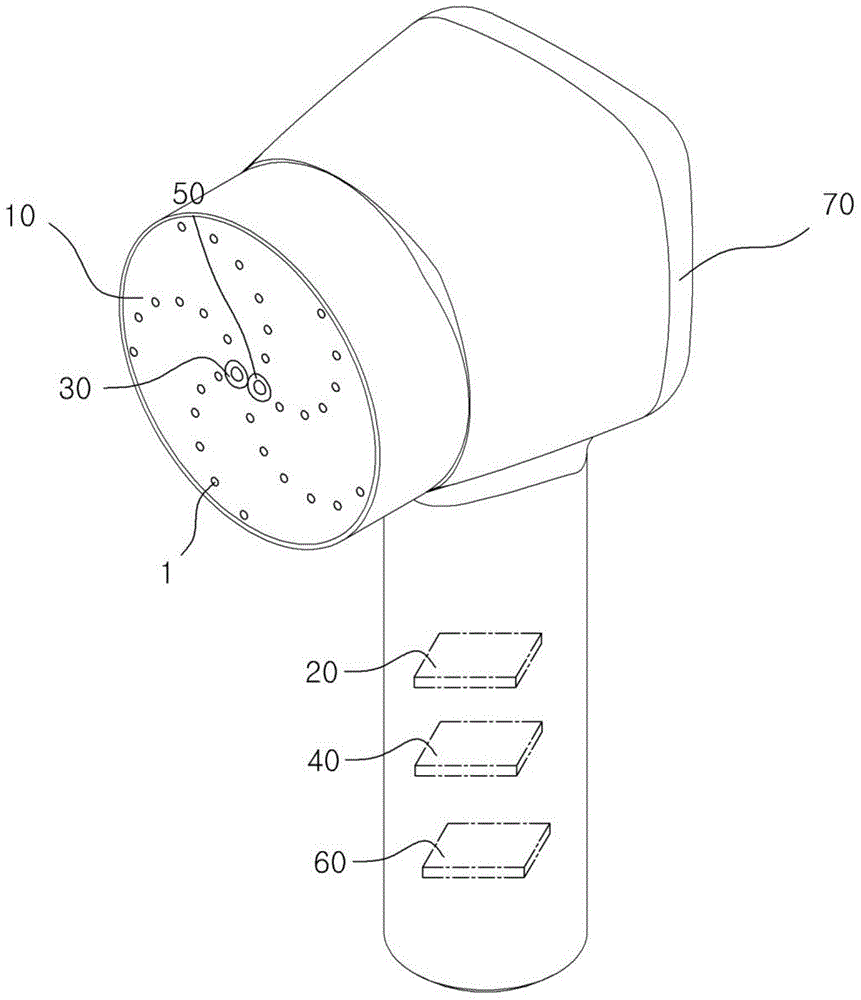

[0040] A multi-channel ultrasonic acoustic camera for machine status monitoring according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 It is a configuration diagram of a multi-channel ultrasonic acoustic camera for machine condition diagnosis of the present invention, figure 2 It is an external view of the multi-channel ultrasonic acoustic camera for machine state diagnosis according to the present invention.

[0041] Such as figure 1 , figure 2 As shown, the multi-channel ultrasonic acoustic camera for mechanical status monitoring according to an embodiment of the present invention includes: an ultrasonic sensing board 10, which is equipped with ultrasonic waves ( A plurality of MEMS ultrasonic sensors 1 of Ultra Sonic); Ultrasonic collecting part 20, it is connected with described ultrasonic sensing plate 10, converts the ultrasonic wave that receives from described MEMS ultrasonic senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com