Method and system for starting an aircraft turboengine

A turboshaft engine, aircraft technology, applied in the direction of engine starting, machine/engine, engine components, etc., can solve problems such as fuel ignition failure or abort, excessive acceleration of the shaft, too fast entry into the ignition window, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

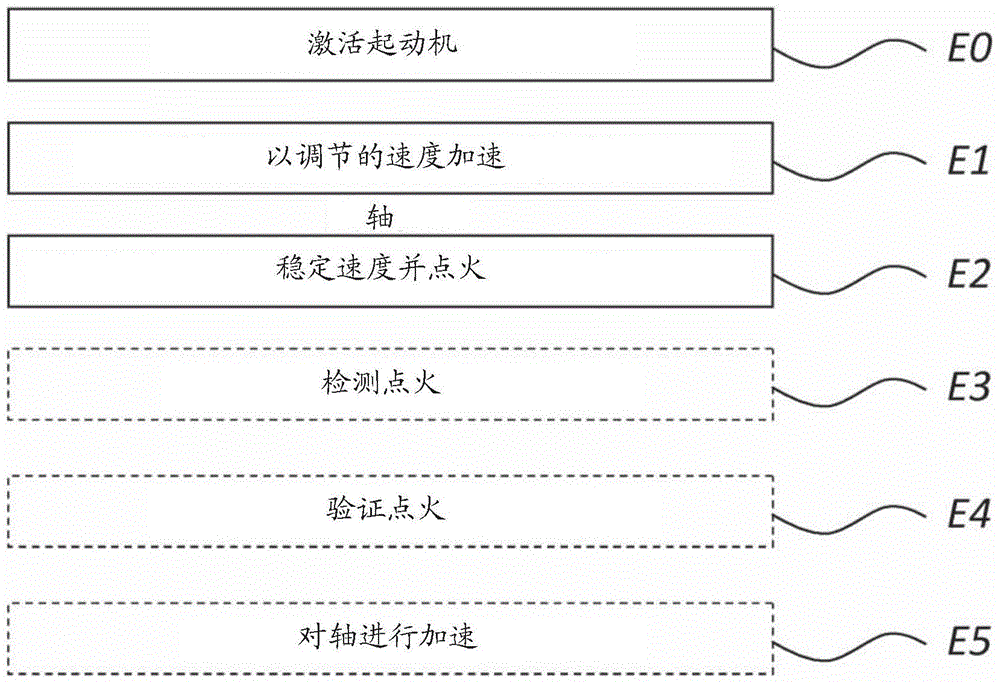

[0066] The method according to the invention is shown in figure 2 Reference image 3 Be explained.

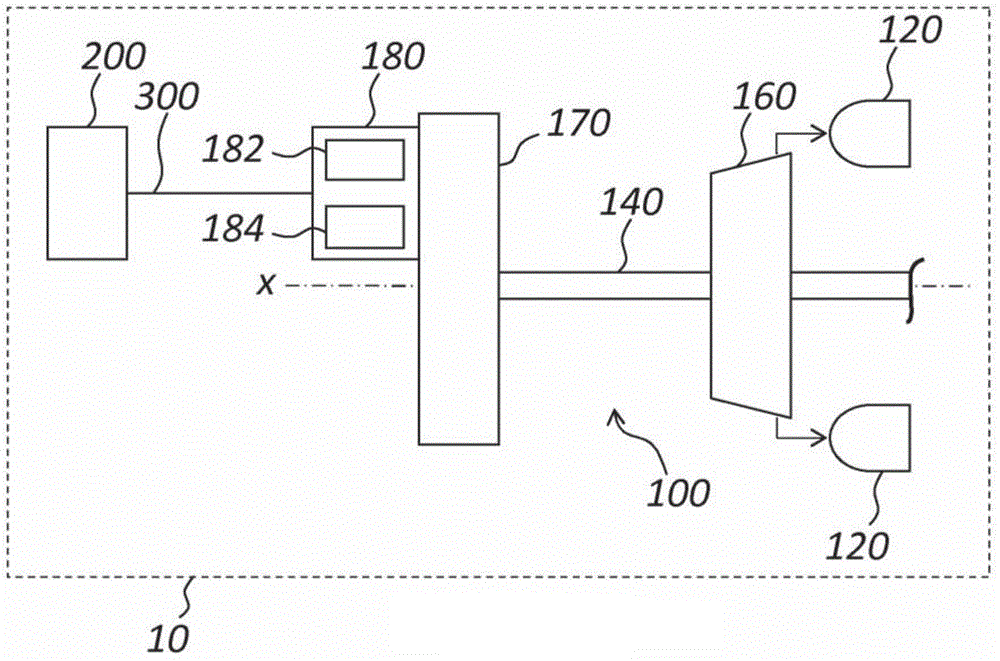

[0067] In step E0, when the turboshaft engine needs to be started on the ground or in flight, an activation command is sent to the electric starter 180, so that the electric starter provides torque to the shaft 140 via the relay transmission 170.

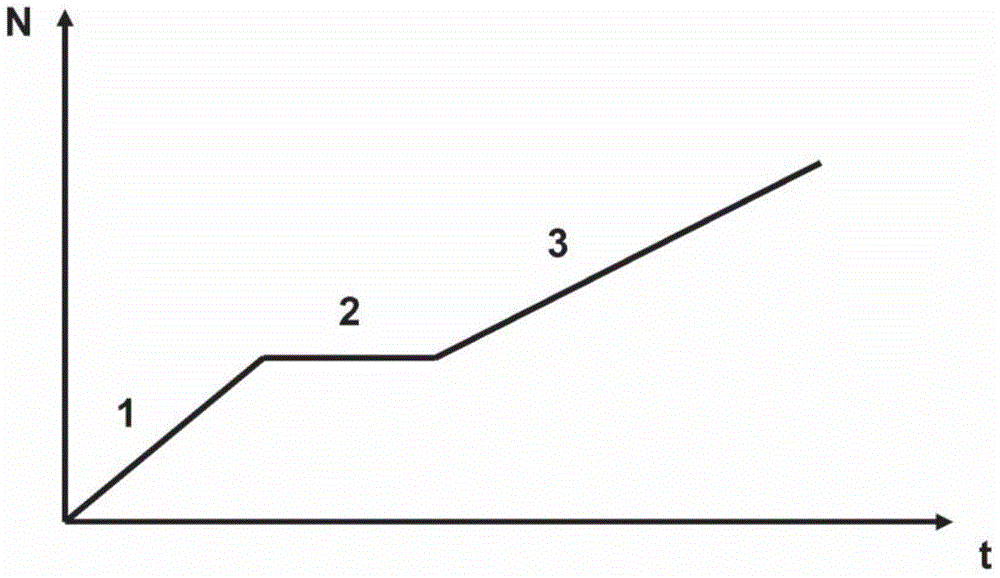

[0068] In step E1, the compressor shaft 140 is accelerated by the starter 180 in the first start phase P1.

[0069] In the first start phase P1, the rotation speed of the shaft 140 is adjusted so that the acceleration of the shaft 140 remains substantially constant in the first phase P1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com