Integrated stem pressing device capable of achieving continuous rolling

An integrated, rolling technology, applied in the processing of tobacco, tobacco, application, etc., can solve the problems of large crushing and low yield of shredded tobacco, and achieve the effect of reducing overlap, equipment input cost and site cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

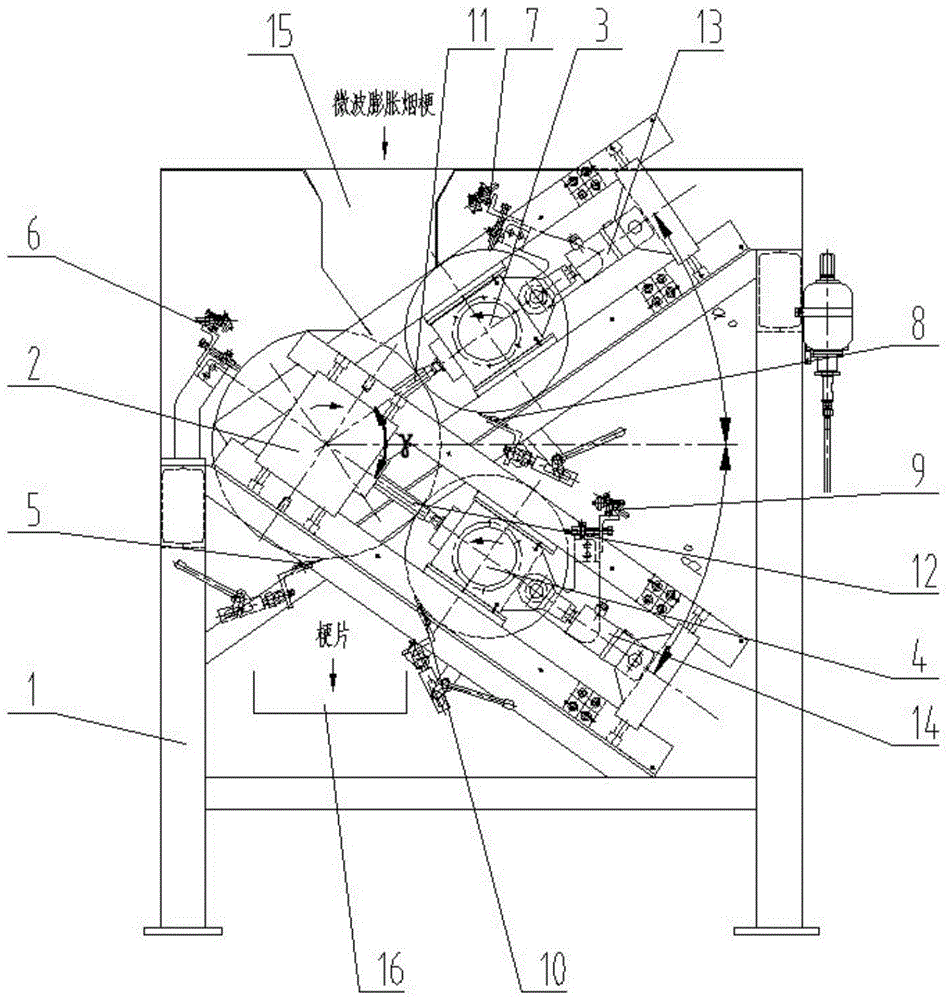

[0017] Such as figure 1 As shown, a kind of continuous rolling integrated stalk pressing equipment of the present invention, the upper moving roller (3), the fixed roller (2) and the lower moving roller (4) are arranged side by side, and the diameter of the fixed roller (2) is 700 mm. The diameter of upper moving roller (3) and lower moving roller (4) is 500mm. The fixed roller (2) of the rolling device is installed on the equipment frame (1), and is fixedly connected with the frame to form a rigid whole. The upper moving roller (3) and the lower moving roller (4) are respectively installed on the machine frame On the rack, the line connecting the center of the upper moving roller and the fixed roller forms an included angle of 30° with the horizontal line, the line connecting the center of the lower moving roller and the fixed roller forms an included angle of 30° with the horizontal line, the upper moving roller (3), the lower moving roller (4) Distributed above and below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com