Acarus killing dust collection all-in-one machine and connecting pipe thereof

An all-in-one machine and vacuum cleaner technology, applied to vacuum cleaners, handles, cleaning equipment, etc., can solve the problems of not being able to adjust the working angle, not being able to add extension tubes, time-consuming and labor-intensive, etc., to improve the user experience, reduce storage space, and remove mites easy work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

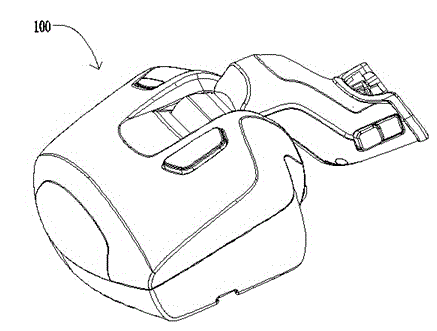

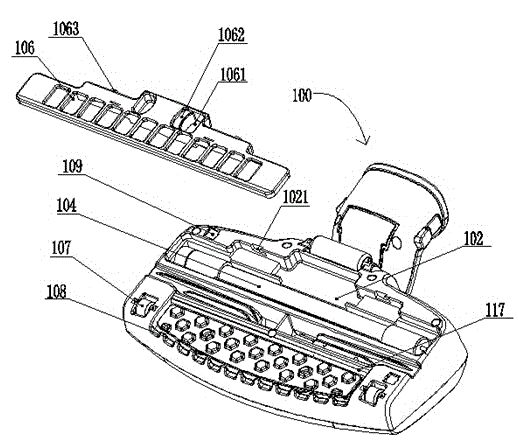

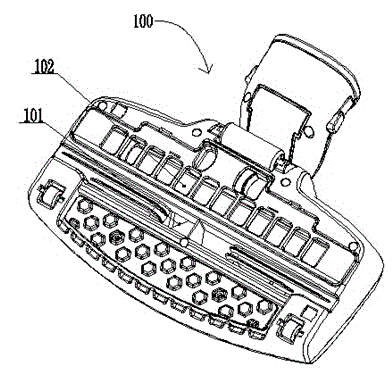

[0054] see Figure 1-Figure 11 , as shown in the legend therein, an all-in-one machine for mite removal and vacuuming includes a mite removal brush 100 and a hand-held vacuum cleaner 200 .

[0055] The mite removal floor brush 100 has a first dust suction port 101 and a lamp housing 102 arranged at its bottom, a first dust outlet 103 arranged at the upper side of its rear end, and a first drive circuit built in its body (Fig. not shown in the figure), the lamp housing 102 is provided with a sterilizing lamp tube 104, the above-mentioned first drive circuit drives and connects the sterilizing lamp tube 104, and the first dust outlet 103 is connected with a connecting pipe, which includes sequentially arranged from front to back The first straight pipe portion 1051, the middle straight pipe portion 1052 and the second straight pipe portion 1053, the lower side of the first straight pipe portion 1051 and the lower side of the middle straight pipe portion 1052 form a first include...

Embodiment 2

[0073] see Figure 12 to Figure 15 , as shown in the legend, the rest is the same as the first embodiment, the difference is that the first dust outlet 103 is provided with an arc-shaped end face A110, and the above-mentioned first connection port is provided with an arc-shaped end face A110 to match The first straight pipe portion 1051 is rotatably connected to the floor mite removal brush 100 so as to realize the rotatable connection of the arc-shaped end surface A110 to the arc-shaped end surface B111.

[0074] In the first state, the mite removal and dust collection function is realized, the arc-shaped end surface A110 and the arc-shaped end surface B111 are located at the first relative position, the first dust outlet 103 is connected to the above-mentioned first connection port, and the bottom of the mite-removing brush 100 is in contact with the first connection port. The bottom of the handheld vacuum cleaner 200 is flush;

[0075] In the fifth state, the mite removal ...

Embodiment 3

[0078] see Figure 16 to Figure 18 , as shown in the legend, the rest is the same as the first embodiment, the difference is that the first straight pipe part 1051 is connected to the mite removal brush 100 through the rotation shaft 112, and the mite removal brush 100 passes through the first The return spring 113 is connected with the floating block 114, the rotating surface of the rotating shaft 112 is provided with a first wedge-shaped protrusion 115, and the floating surface of the floating block 114 is provided with a second wedge-shaped protrusion 116, in the first state, the rotation of the rotating shaft 112 The surface and the floating surface of the floating block 114 are at the first relative position, the first wedge-shaped protrusion 115 and the second wedge-shaped protrusion 116 are staggered, the first wedge-shaped protrusion 115 is connected with the floating surface of the floating block 114 and the second wedge-shaped protrusion 116 is mated with the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com