Sand-water separator

A sand-water separation and water storage tank technology, applied in the feeding/discharging device of the sedimentation tank, the sedimentation tank, etc., can solve the problems of low efficiency, high cost, affecting the discharge of sewage up to the standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

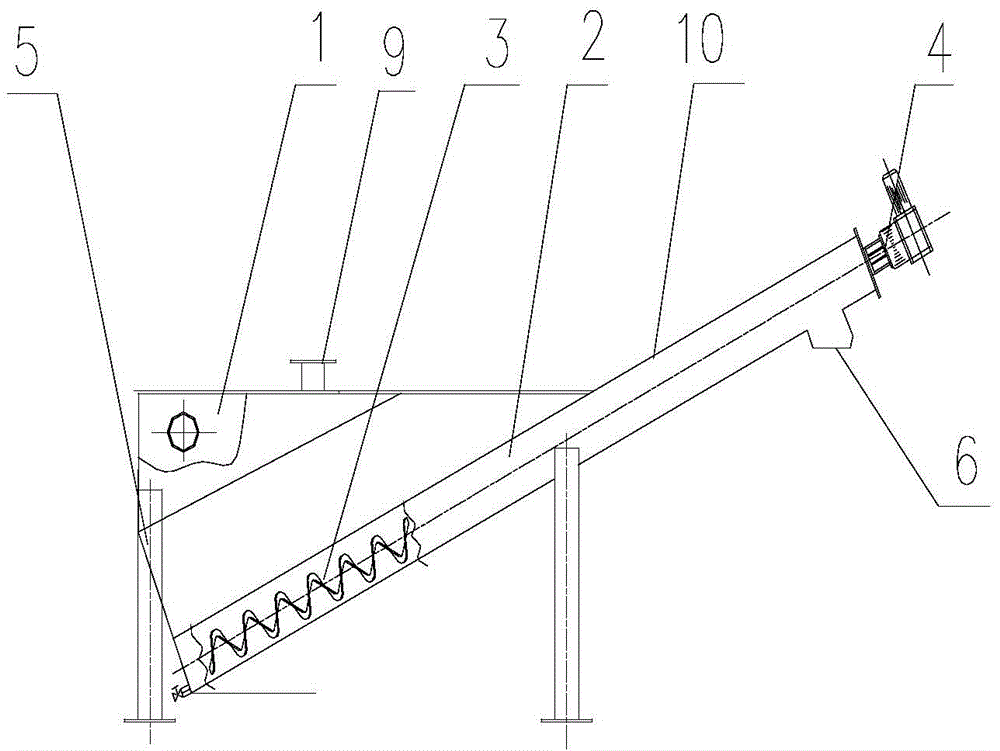

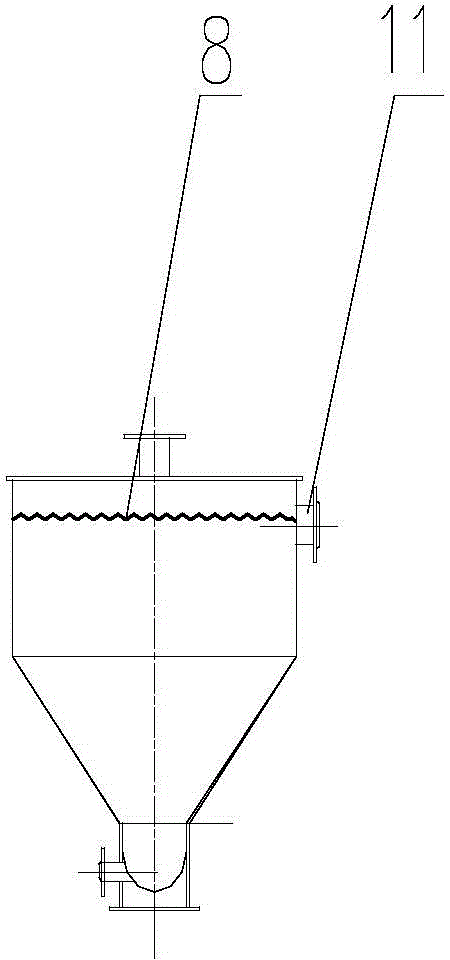

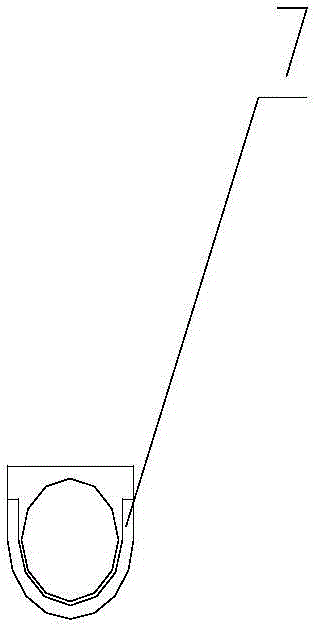

[0014] Its structure is as shown in the figure: a sand-water separator, including a water storage tank 1, a U-shaped delivery tank 2, a spiral body 3, a driving device 4 and a bracket 5, and one end of the U-shaped delivery tank is obliquely arranged on the side of the water storage tank The bottom and the other end are connected to the driving device, and the U-shaped conveying trough is provided with a sand discharge port 6 close to the driving device; the spiral body is located in the U-shaped conveying trough, and a rubber liner is also arranged between the spiral body and the U-shaped conveying trough 7. A zigzag overflow weir 8 is provided at 15-20 cm above the inner side of the water storage tank; a water inlet 9 is provided on the top of the water storage tank; a drain port 11 is provided on the upper side of the water storage tank; The spiral body adopts a stainless steel shaftless spiral body; the U-shaped conveying trough is provided with a cover 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com