Automated express sorting device

A sorting device and push device technology, which is applied in the direction of sorting, transportation and packaging, and conveyor objects, etc., can solve the problems of low automation level and slow express sorting speed, and achieve high automation level and fast sorting speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

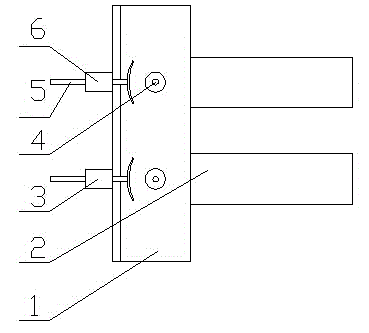

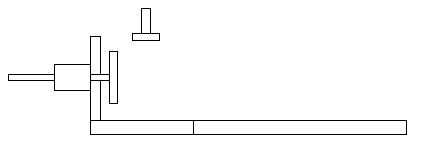

[0015] Such as figure 1 As shown, an automatic express sorting device includes a main conveyor belt 1, a branch conveyor belt 2, a push device 3, and a detection device 4; the main conveyor belt 1 is vertically interlaced with each branch conveyor belt 2, and a detection device is installed directly above each interlaced position. Device 4, pushing device 3 is installed on the staggered position, and this pushing device 3 is facing branch conveyor belt 2; Only one courier can be placed in each position of the transmission belt 1 and the branch conveyor belt 2; the push device 3 is composed of a push hand 5 and a power drive 6; the detection device 4 is a multi-functional camera, and each detection device 4 only identifies the corresponding next station Address; push device 3 and detection device 4 are connected to the main controller by data lines; when a courier is unloaded from the express transport vehicle at the previous station to the main conveyor belt 1, and passes thro...

Embodiment 2

[0017] The power drive of the pushing device 3 can be driven by a motor, or can be controlled by hydraulic pressure or air pressure, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com