Automotive stabilization rod double-end one-time forging and forming device and using method thereof

A stabilizer bar and compression molding technology, which is applied in vehicle parts, transportation and packaging, railway car body parts, etc., can solve the problems of lack of positioning device stabilizer bar length and parallelism of both ends, low production line efficiency, and high rejection rate. The effect of reducing processing cost, high production efficiency and stable quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

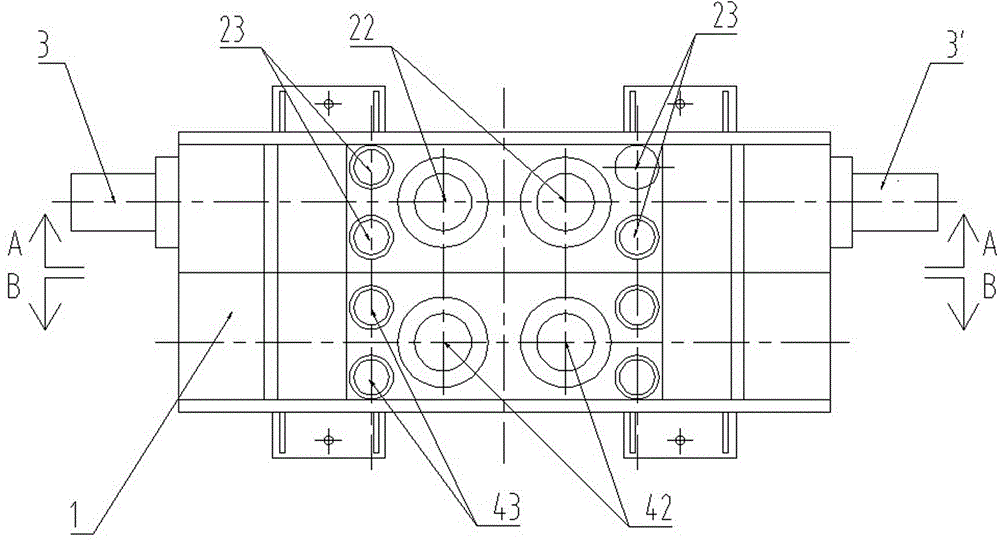

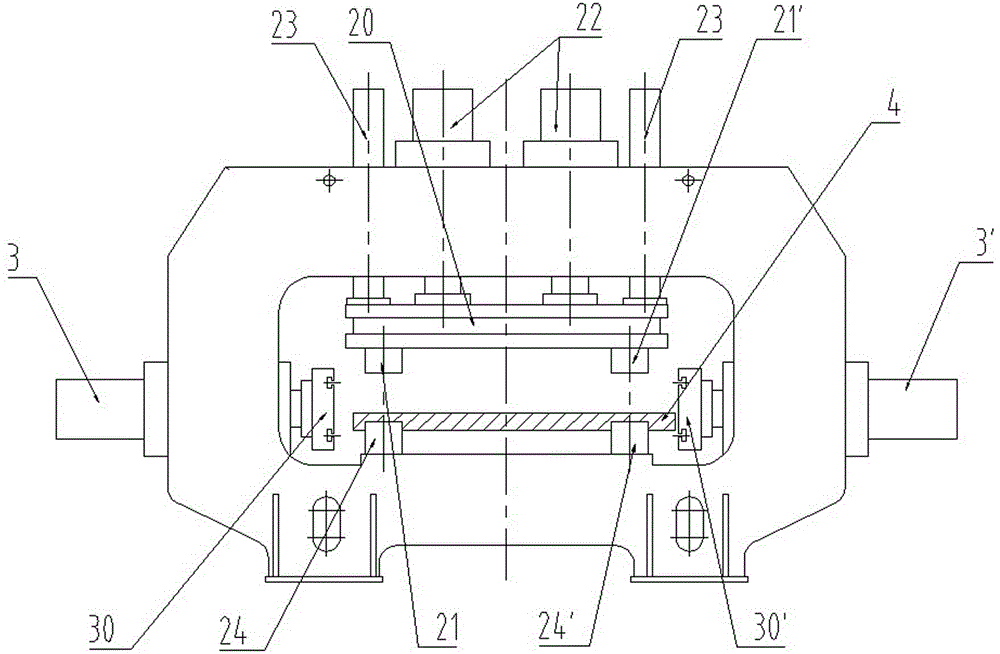

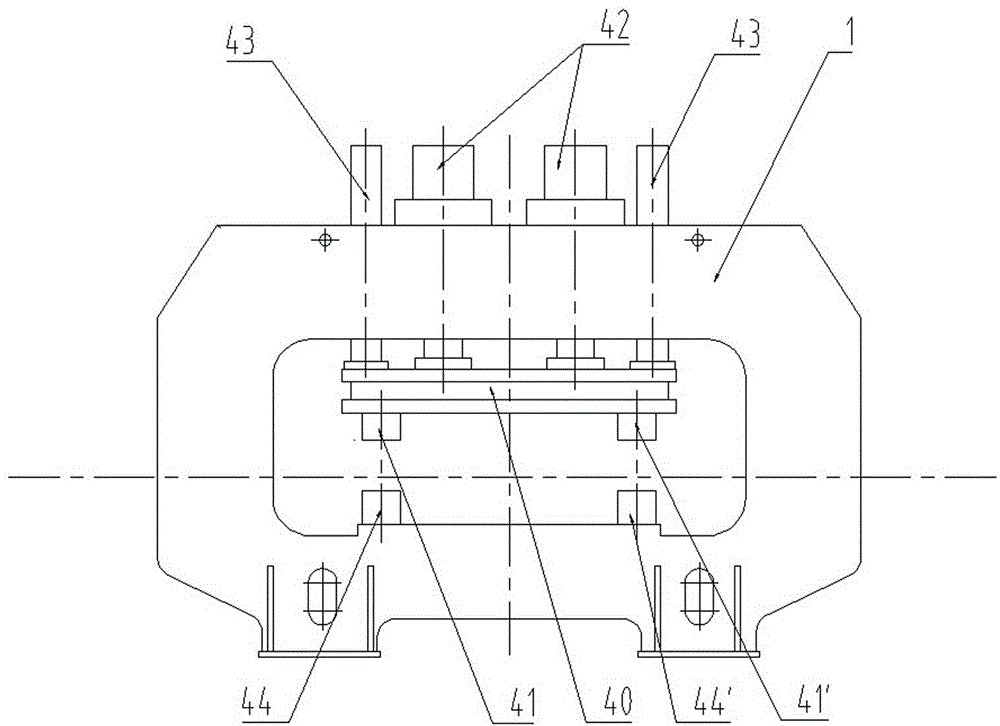

[0025] Such as figure 1 , figure 2 , image 3 It can be seen that the automobile stabilizer bar double-head primary forging forming device of the present invention includes a frame 1, and is characterized in that: a workpiece clamping device is arranged in the frame 1 for clamping the workpiece along the length direction of the frame 1; It includes an upsetting device matched with the workpiece clamping device, which is used for upsetting the end of the clamped workpiece; and a forging device matched with the upsetting device, used for forging and forming the end of the upset workpiece.

[0026] The upsetting device includes left and right extrusion cylinders 3, 3' arranged on the frame 1, and the ends of the piston rods of the left and right extrusion cylinders 3, 3' are provided with left and right upsetting transverse dies. Seat 30, 30'.

[0027] The workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com