A zoct type bogie bolster fixed lever fulcrum seat assembly welding tool

A technology of fixed levers and assembly welding tooling, which is applied in the field of vehicle bogies, can solve the problems of assembly welding size out-of-tolerance, achieve light weight, improve assembly welding production efficiency, and eliminate uncertain factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

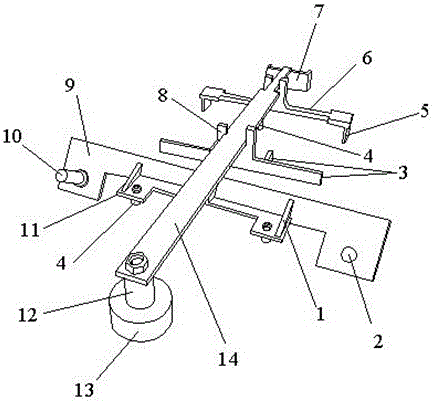

[0018] Look figure 1 , figure 1 It shows the structure schematic diagram of this fixed lever support point assembly welding tool of the present invention. It can be seen from the figure that the tool of the present invention mainly includes the following parts: overall, the tool of the present invention is similar to the structure of an aircraft, and the backbone is A center positioning plate 14, all the other components are attached on the center positioning plate 14. The place ahead of the central positioning plate 14 is a centering plate 13 and a centering pin 12 of the bolster heart plate, which are used for the positioning of the bolster heart plate.

[0019] The tail of the central positioning plate 14 is the tailstock positioning and welding device 7, which is used for positioning the bolster tailstock. The tailstock positioning and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com