Assembly welding technological method of ultra-supercritical coal million-kilowatt steam turbine generator stator base

A technology for a steam turbine generator and a stator frame, which is applied in the field of assembly and welding technology for the stator frame of an ultra-supercritical coal-fired million steam turbine generator, can solve problems such as high cost, achieve high risk, improve product quality, and improve product quality. The effect of reducing the influence of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

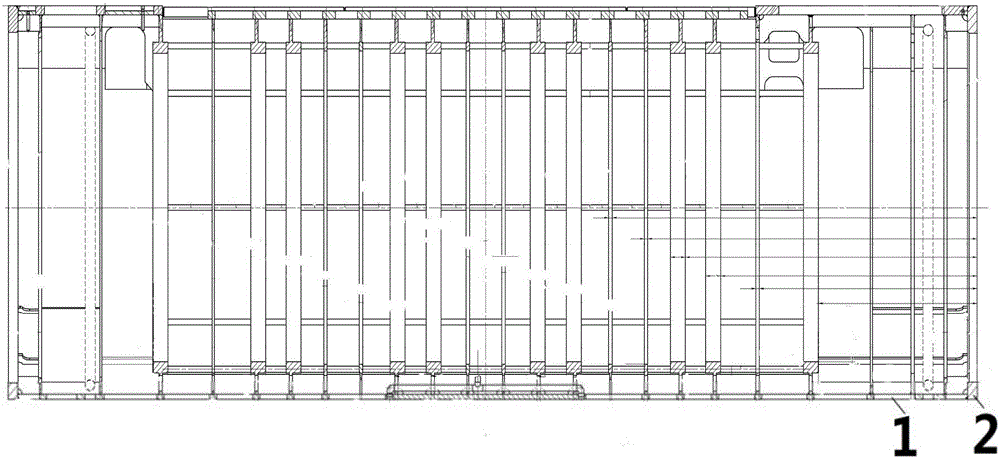

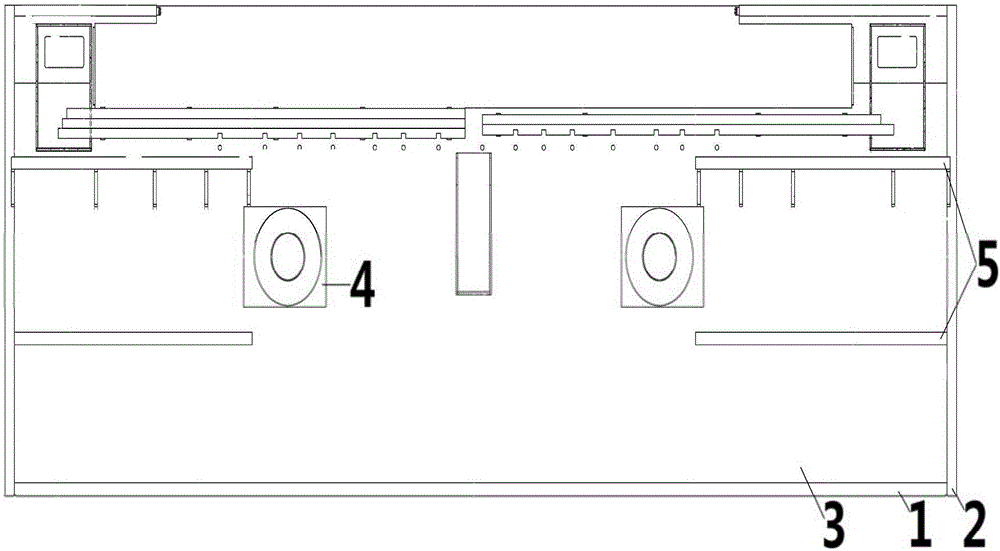

[0010] (1) Use CNC gas cutting machine, semi-automatic gas cutting machine or shearing machine to blank, flatten, form and sandblast the semi-finished parts required for machine base assembly according to the requirements of the drawings; (2) According to the requirements of the drawings, the end plates, partitions and Parts such as the inner ring are sub-assembled and welded, and CNC machining is carried out after completion; (3) All pipelines are prepared and bent according to the requirements of the drawings, the inside of the pipelines is cleaned, and sealed with adhesive tape and pipe caps; (4) Skeleton assembly: such as figure 1 Put the axial support 1 and the top side plate on the platform, adjust the unevenness and fix them by lap welding, place the steam and excitation end plates 2 on the two ends of the axial support 1 according to the size of the drawing, adjust the verticality and fix them by lap welding, and pass The end plates on both sides determine the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com