Printing head, three-dimensional printer and three-dimensional printing method

A technology of 3D printers and print heads, which is applied in the field of melt-extruded print heads and 3D printers, can solve problems such as reducing the printing accuracy of 3D objects, and achieve the effects of improving printing efficiency, simplifying structure, and multiple selection ranges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

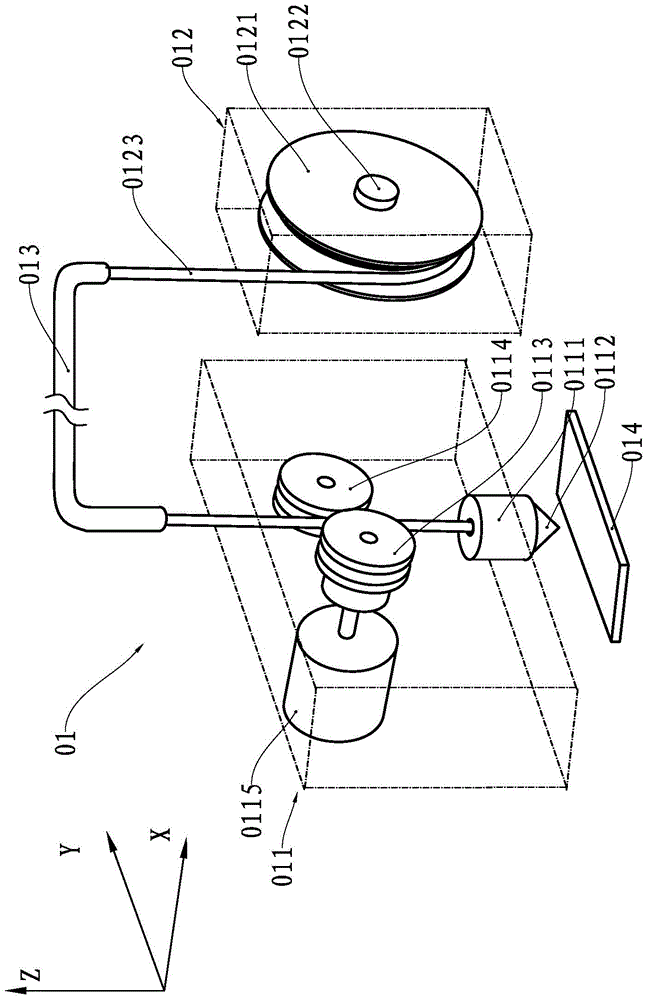

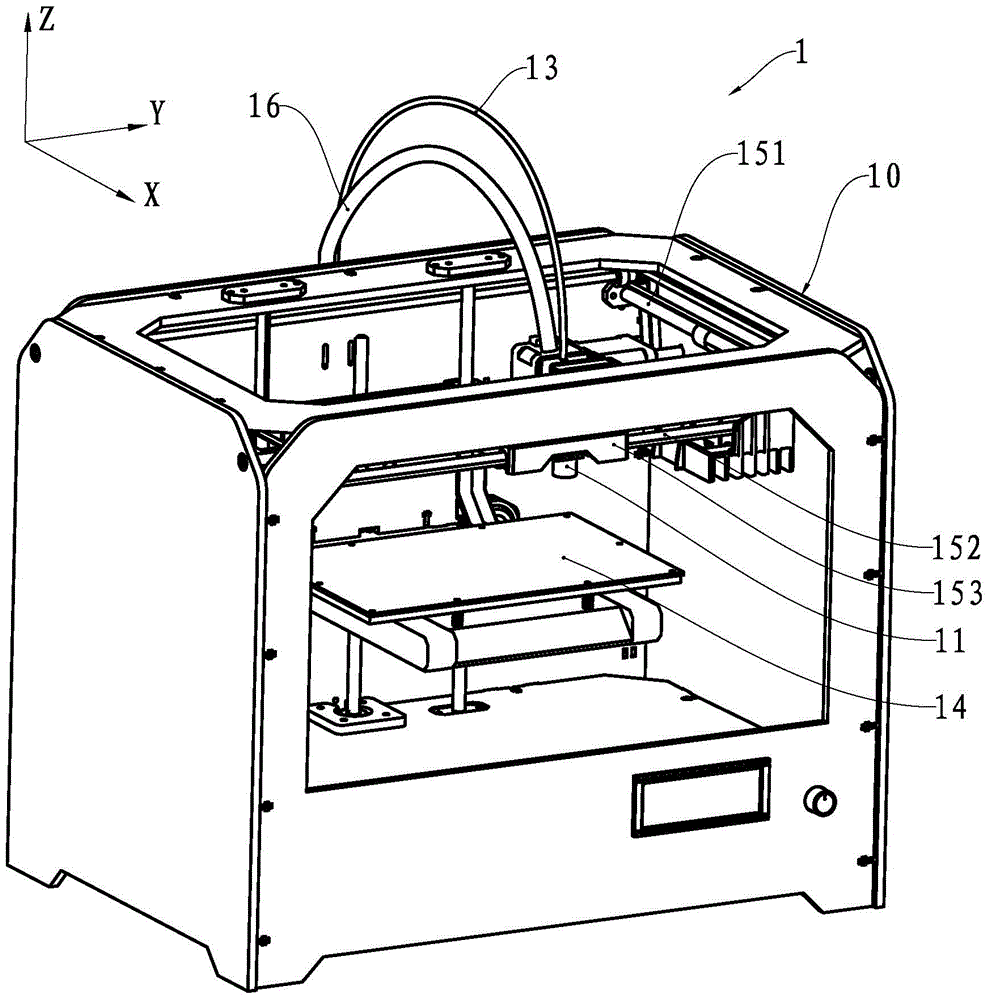

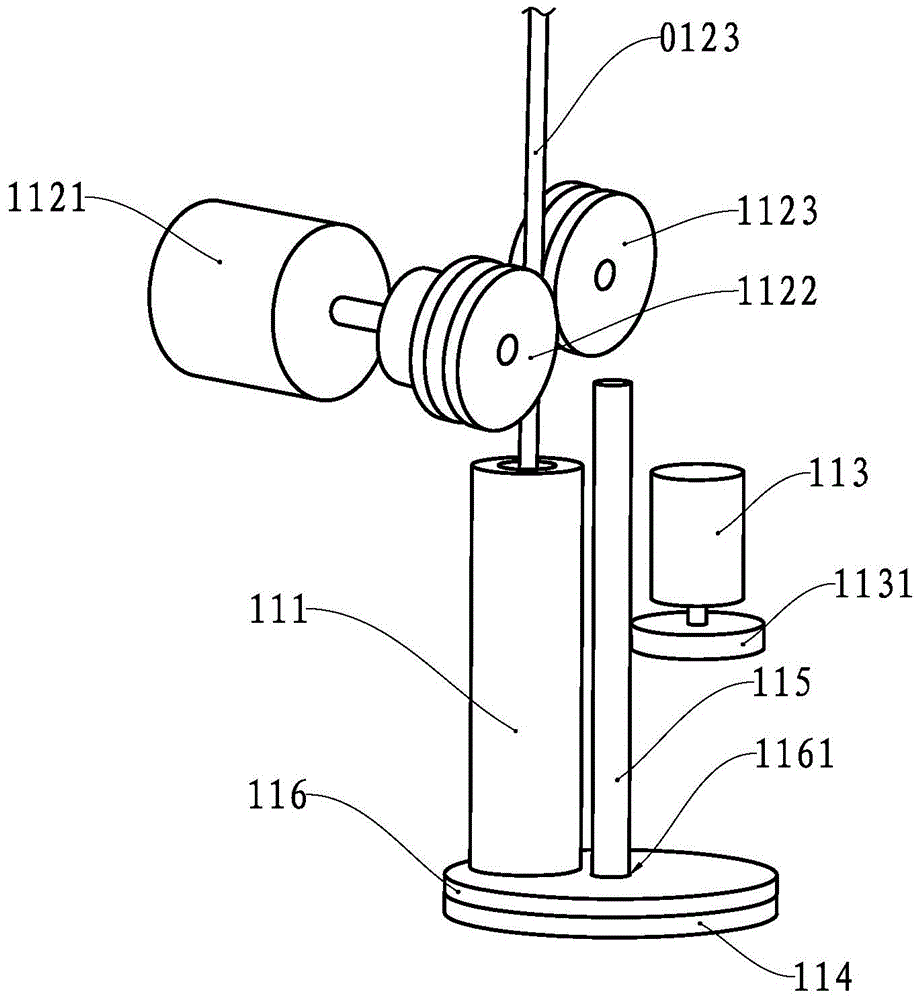

[0040] see figure 2 , The three-dimensional printer 1 is composed of a frame 10 and a print head 11 installed on the frame 10, a feeding device, a hose 13, a stage 14, a traveling mechanism and a control unit. The traveling mechanism has a first pair of guide rails 151 arranged in parallel along the X-axis direction, a second pair of guide rails 152 and a mounting seat 153 arranged in parallel along the Y-axis direction; the two ends of the second pair of guide rails 152 are installed on the first pair of guide rails 151 and can Moving along it, the print head 11 is installed on the second pair of guide rails 152 through the mounting seat 153, and the control unit controls the driving device on the traveling mechanism to drive the mounting seat 153 to move along the second guide rail 152 and drive the second guide rail 152 to move along the first guide rail 151 Move, so as to drive the print head 11 to move in the horizontal X-Y plane, and control the stage 14 to move along t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com