A 3D printing device with multiple nozzles and printing method thereof

A 3D printing, multi-nozzle technology, applied in the field of 3D printing, to save time and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

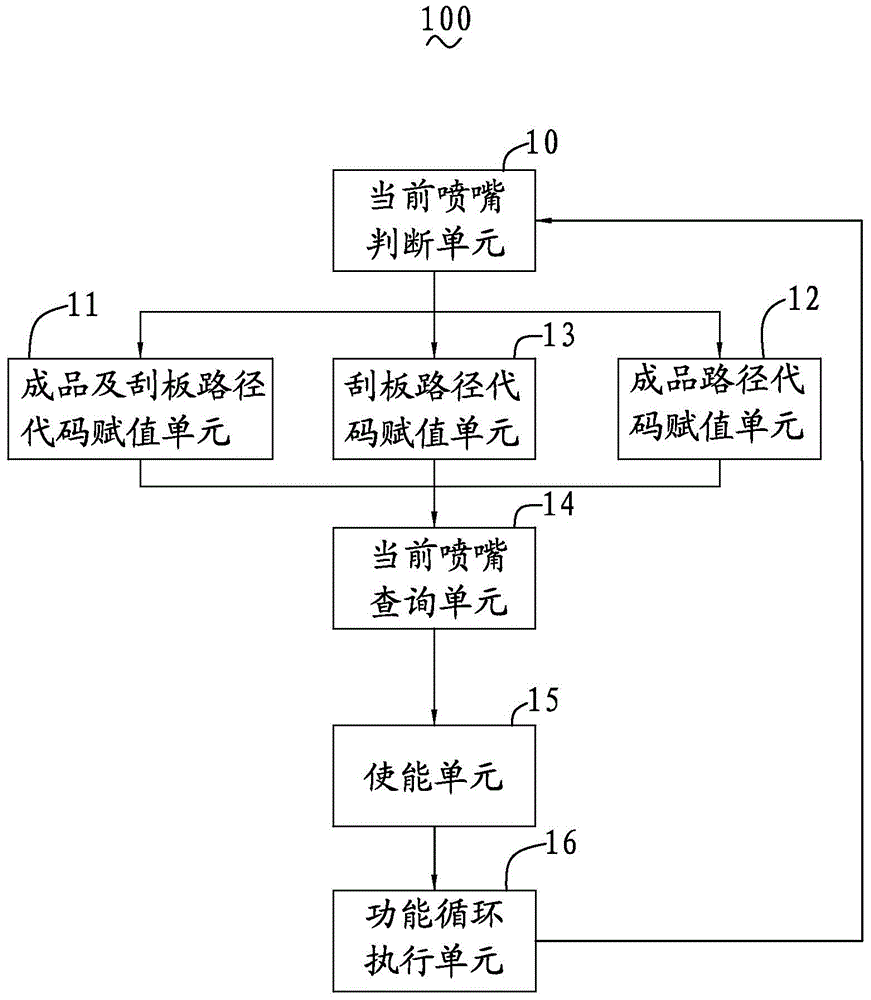

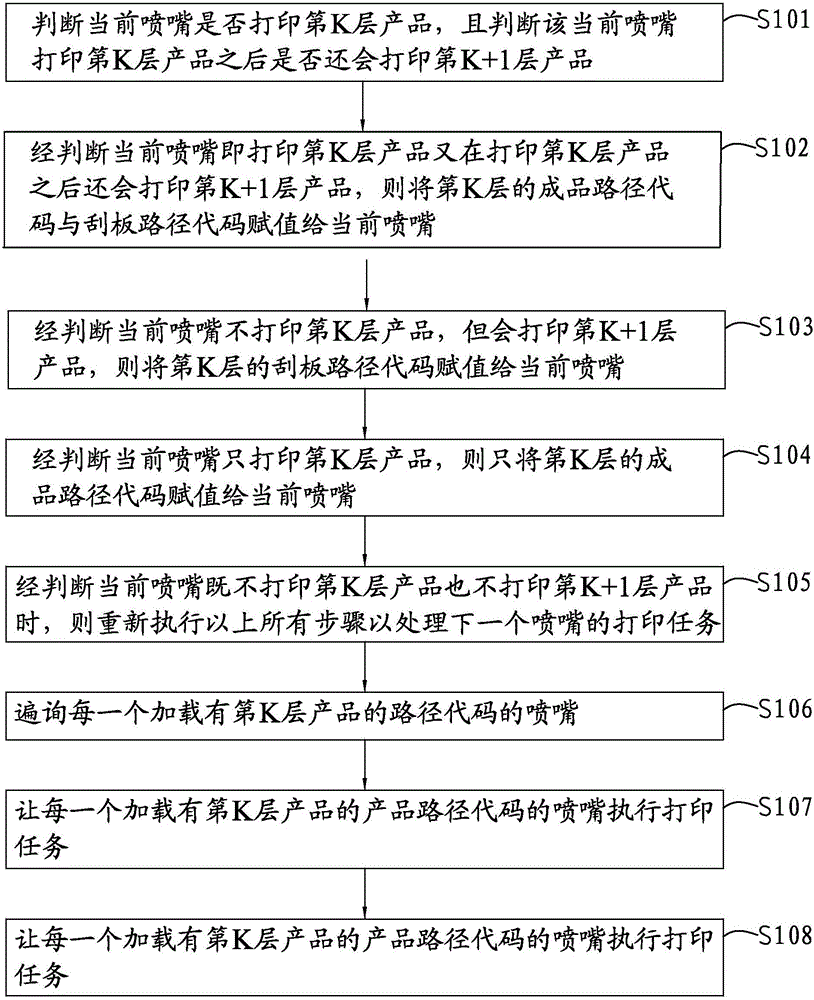

[0033] Such as figure 1 As shown, it is a functional block diagram of a 3D printing device 100 with multiple nozzles provided by the present invention. The product printed by the 3D printing device with multiple nozzles 100 includes at least one finished product and a plurality of scrapers, wherein the finished product is formed by printing K layers of the 3D printing device, K≥1, and K is a natural number. The plurality of scrapers are spaced apart from the finished product. When printing, the finished product can be one or multiple. In this embodiment, just to illustrate the present invention, the 3D printing device 100 with multiple nozzles prints one finished product in one printing process. The finished product is printed with multiple hot-melt materials, therefore, multiple nozzles are required to perform them separately, however, the type of hot-melt material used to print the finished product is not necessarily consistent with the individual nozzles of the 3D printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com