Waste heat reutilization control system

A control system and central control technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problem of lack of waste heat reuse system, achieve excellent reproducible operability, increase profits, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be briefly described below in conjunction with the drawings.

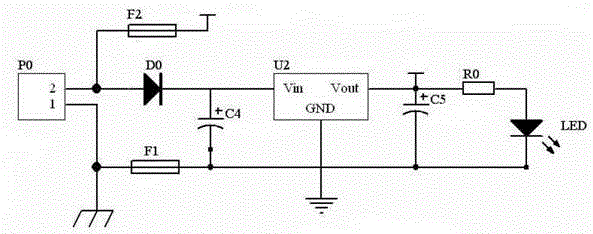

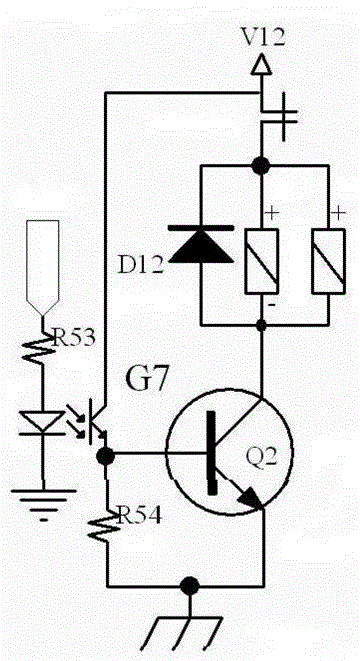

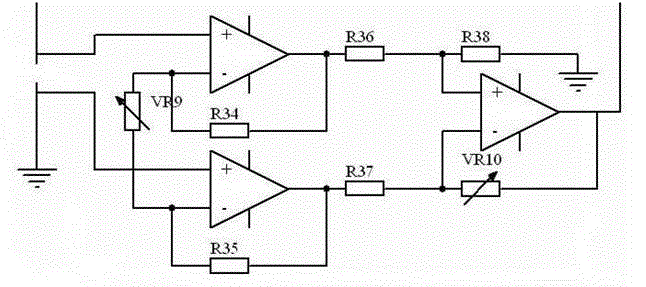

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 , Figure 13 , Figure 14 As shown, the waste heat reuse control system is mainly composed of a regulated power supply circuit 1, a relay state drive circuit 2, a pressure sensor constant current power supply circuit 3, a pressure signal amplifier circuit 4, a temperature signal input port 5, a temperature signal amplifier circuit 6, and a central Controller work oscillation circuit 7, valve switch status display circuit 8, central control chip circuit 9, three-way valve status control circuit 10, reset circuit 11, actuator control circuit 12, and A / D conversion voltage reference circuit 13. The relay state drive circuit 2 is electrically connected to the pressure signal amplifier circuit 4, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com