Combustion machine and steam turbine combined circulation system for gas boiler

A gas-fired boiler and circulation system technology, applied in the direction of joint combustion mitigation, etc., can solve the problems of unreasonable use, low net power supply efficiency, limited optional equipment, etc., and achieve high consumption ratio and boost power consumption Small and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

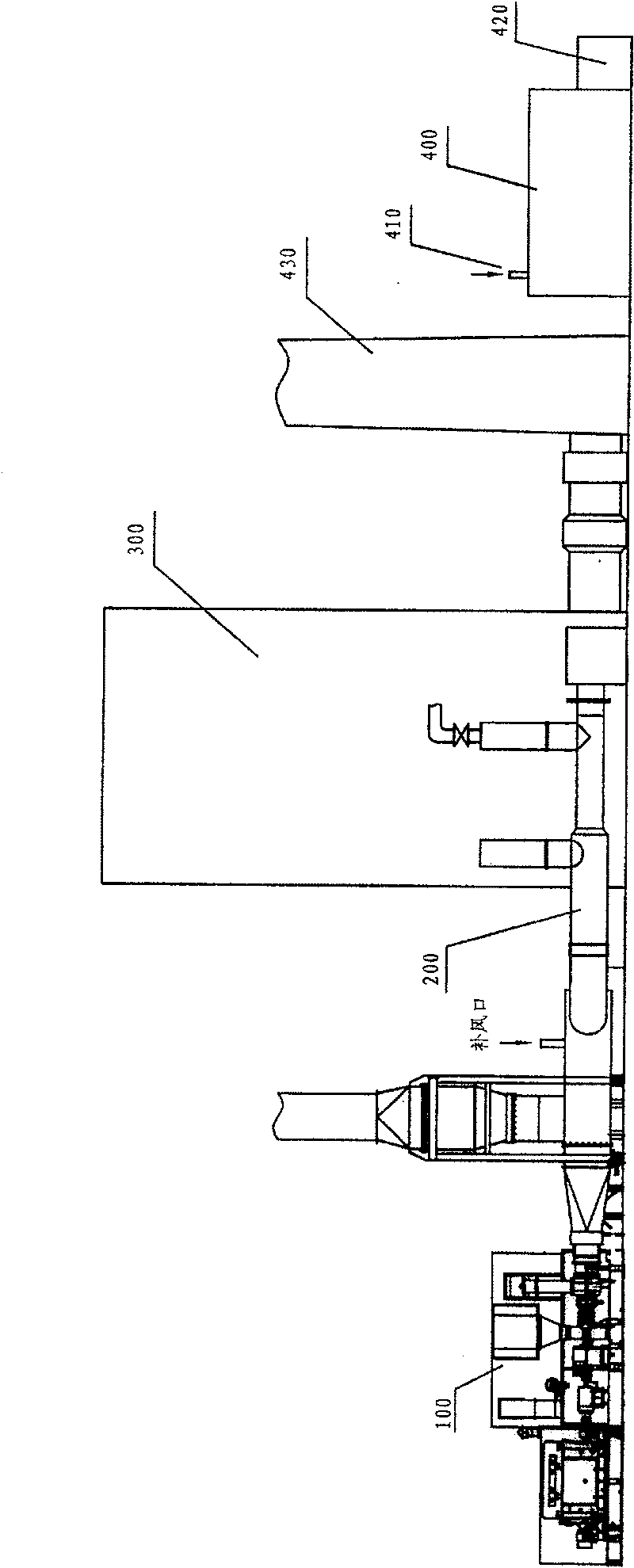

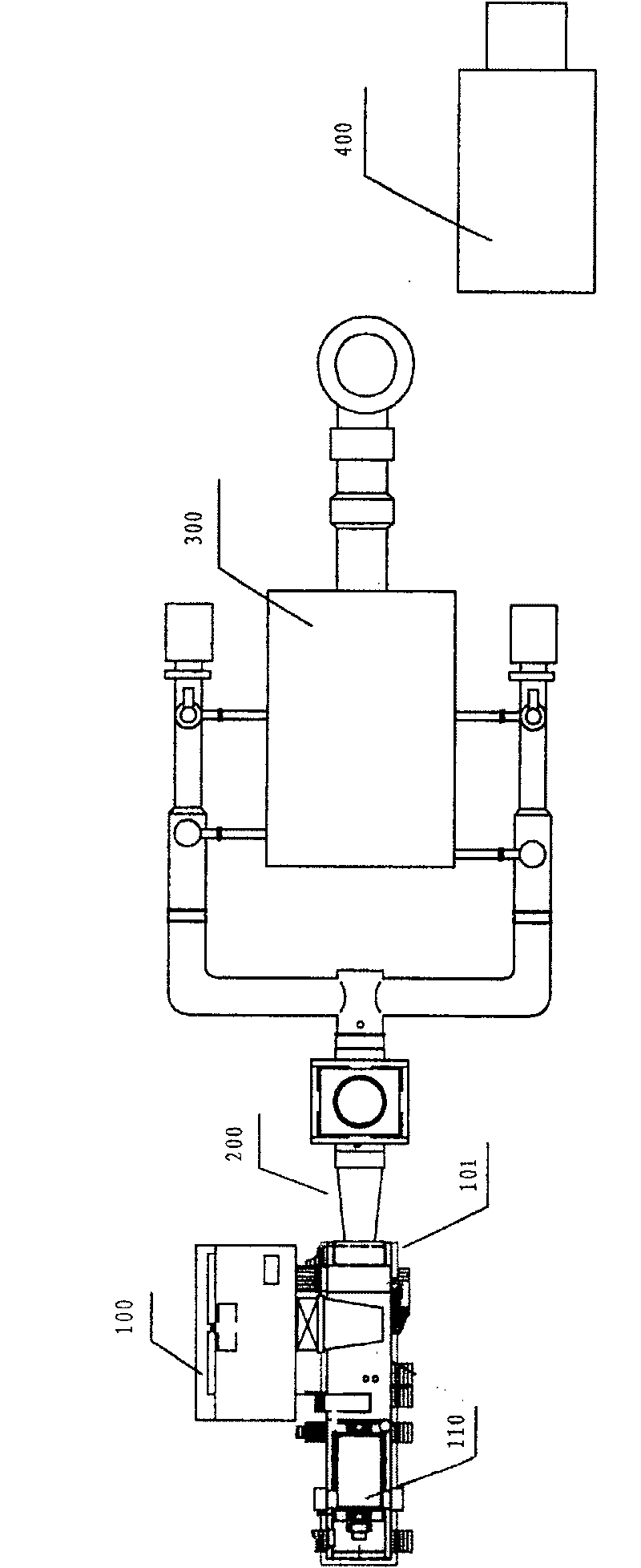

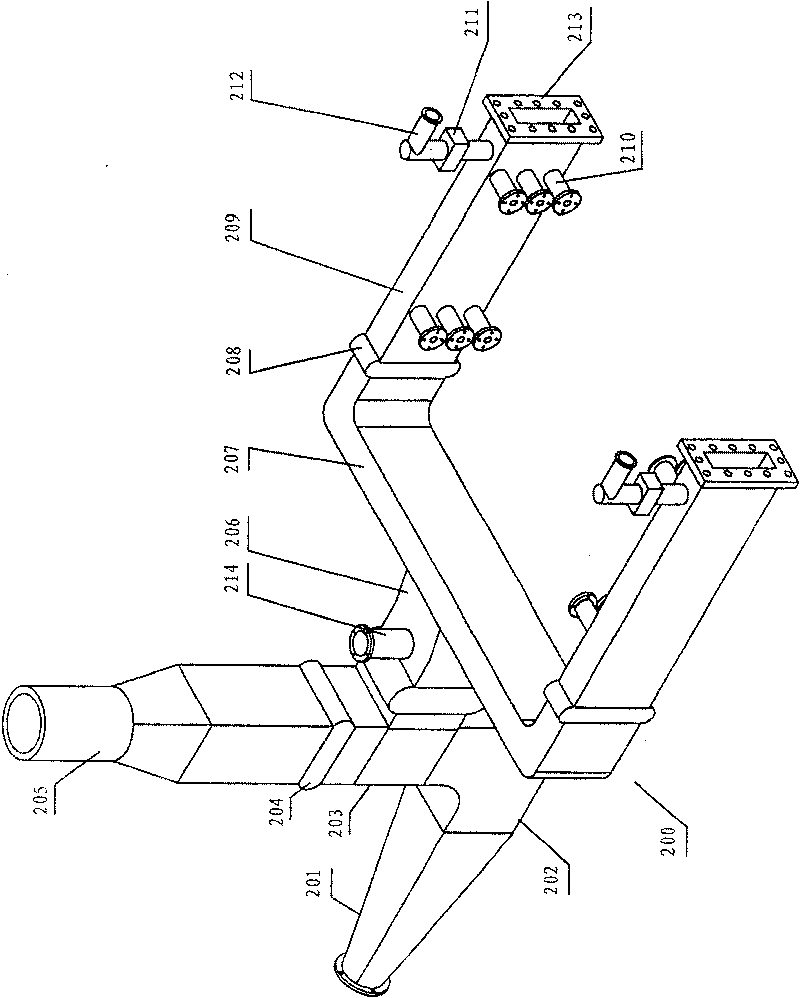

[0020] see figure 1 , the gas turbine-steam turbine combined cycle system of the present invention has a gas boiler, a gas turbine device, and a steam turbine device, and the combustion-supporting air inlet 3083 at the bottom of the gas boiler 300 passes through a hot air duct 200 and the turbine exhaust port of the gas turbine device 100 101 communication, the turbine exhaust of the gas turbine device directly enters the negative pressure combustion furnace of the gas boiler as combustion air to participate in combustion, the superheated steam outlet 301 of the gas boiler communicates with the steam inlet device of the steam turbine 400, and the gas boiler produces The superheated steam is converted into mechanical energy in the steam turbine device; the gas-fired boiler uses blast furnace gas as the main fuel, and the furnace body of the gas-fired boiler is equipped with a negative pressure combustion furnace 309, a water wall device 310, a superheated grate 302, and a combus...

Embodiment 2

[0035] A gas turbine-steam turbine combined cycle system using a gas boiler, comprising a gas boiler, a gas turbine device, and a steam turbine device, the combustion-supporting air inlet at the lower part of the gas boiler communicates with the turbine exhaust port of the gas turbine device through a hot air duct, The superheated steam outlet of the gas boiler communicates with the steam turbine intake device; the gas turbine device has a heat value of 5000-36000KJ / NM 3 combustible gas as fuel; the gas-fired boiler uses natural gas, blast furnace-converter mixed gas, underground gasification gas, coal gas, coal bed methane, chemical tail gas, and biogas as fuel, and the furnace body of the gas-fired boiler It is equipped with a negative pressure combustion furnace, a water wall device, a superheated grate, and a combustion device, and the upper part of the gas boiler is provided with a steam drum.

[0036] In this embodiment, the structures of the gas boiler, gas turbine devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com