A kind of manufacturing method of train turnout and steel for train turnout

A manufacturing method and turnout technology, which is applied in the field of iron and steel metallurgy, can solve the problems of reducing the service performance of steel for train turnouts, and achieve the effects of preventing tissue inheritance, ensuring service performance, and fine and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The chemical composition of the forgings of embodiment 1, embodiment 2 and embodiment 3, and the balance other than this is Fe, and may also contain unavoidable impurities (mass percentage, wt~%) see the following table:

[0030]

[0031] Example 1:

[0032] After forging, the 35CrMoSiMnVTiB steel forgings for railway turnouts are directly sent to the furnace, cooled to 400°C, and kept for 4 hours; then the forgings after heat preservation are heated at 950°C, kept for 8 hours, and then furnace cooled; Furnace cooling to 620°C, heat preservation for 12 hours, then air cooling to the surface temperature of the forgings at 220°C; the air-cooled forgings were reheated to 860°C, and air cooling to room temperature after heat preservation for 4 hours.

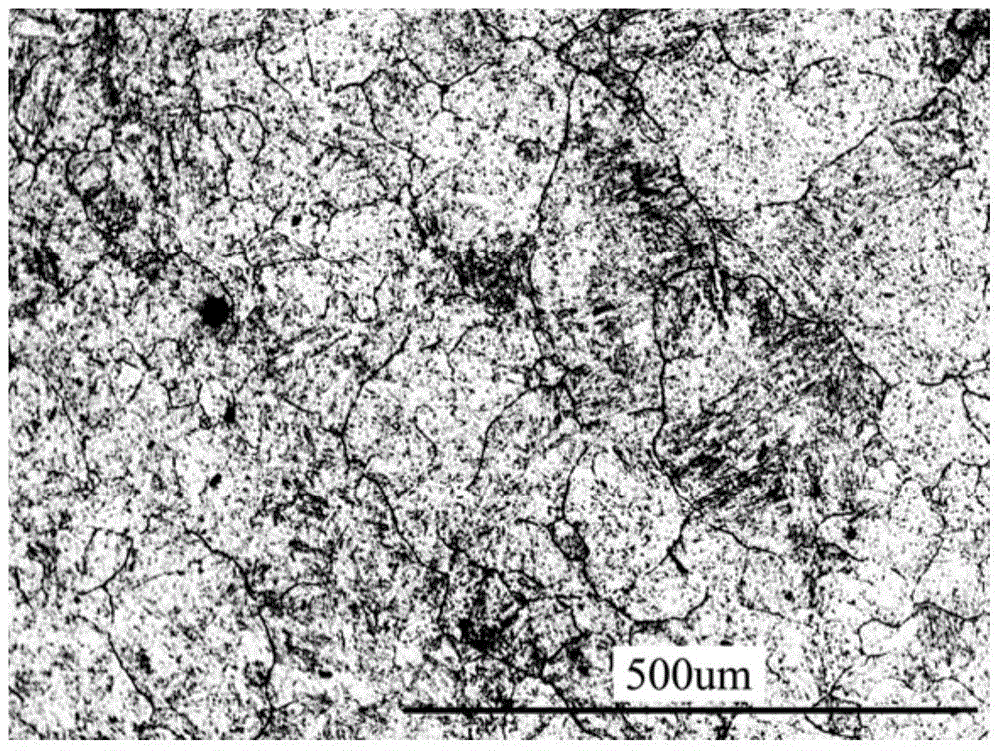

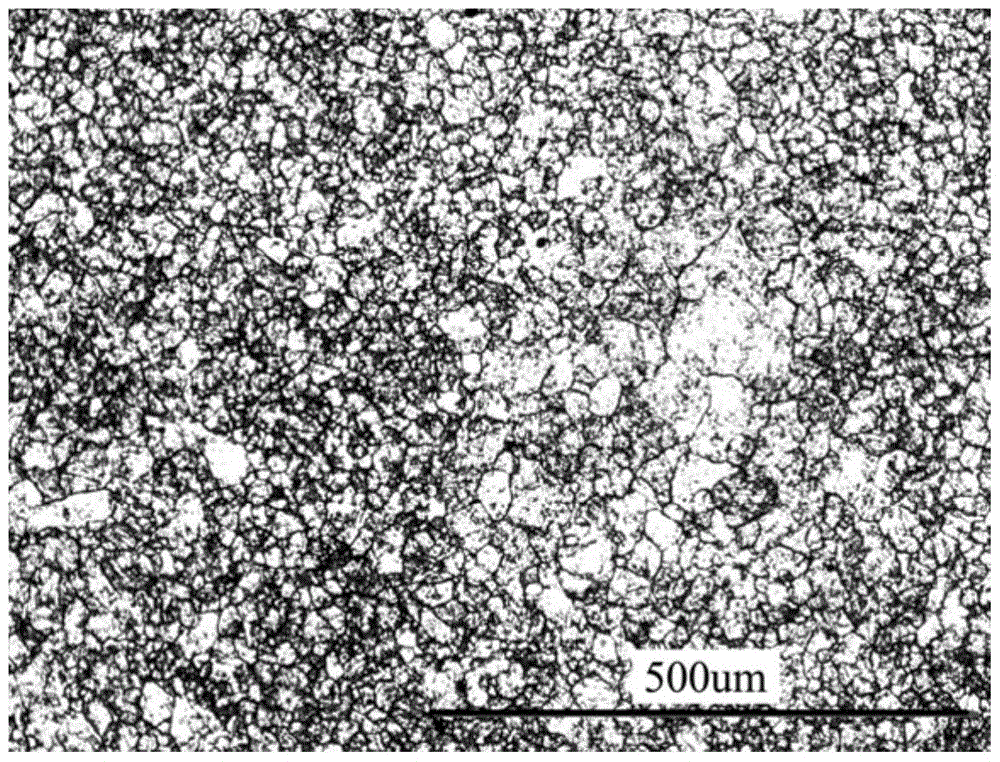

[0033] figure 1 Be the original grain state of embodiment 1, figure 2 For the grain state of the core of the forging after the forging is heat-treated according to the above technical scheme, it can be seen that the gra...

Embodiment 2

[0035] After forging, the 35CrMoSiMnVTiB steel forgings for railway turnouts are directly sent to the furnace, cooled in the furnace to 500°C, and kept for 3 hours; then the forgings after heat preservation are heated at 990°C, kept in the furnace for 6 hours, and then cooled in the furnace; Furnace cool to 660°C, keep warm for 10 hours, then air cool to forging surface temperature 210°C; air cooled forgings are reheated to 900°C, keep warm for 2 hours, then air cool to room temperature.

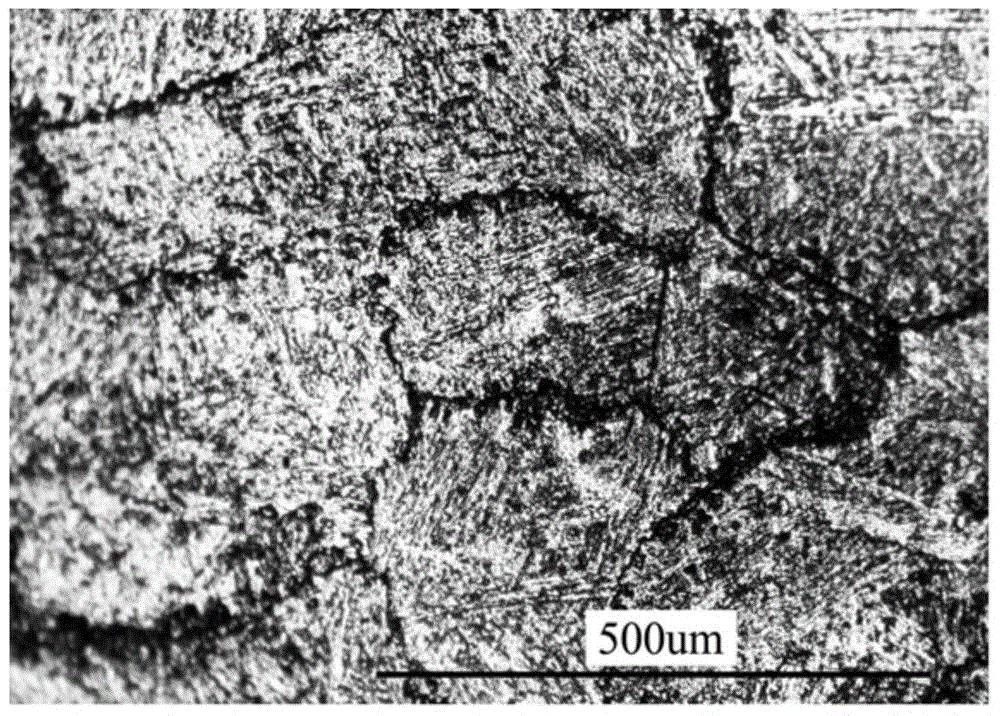

[0036] image 3 Be the original grain state of embodiment 2, Figure 4 For the grain state of the core of the forging after the forging is heat-treated according to the above technical scheme, it can be seen that the grains are obviously uniform and refined after the forging is heat-treated by the present invention.

Embodiment 3

[0038] In the present invention, the 35CrMoSiMnVTiB steel forgings for railway turnouts after forging are directly sent to the furnace for heating, the furnace is cooled to 450°C, and kept warm for 3.5 hours; then the forgings after heat preservation are heated at a heating temperature of 970°C, and the furnace is heated for 7 hours. Cooling; furnace cooling to 640°C, holding for 11 hours and then air cooling to the surface temperature of the forging at 240°C; reheating the air-cooled forging to 880°C, holding for 3 hours and then air cooling to room temperature.

[0039] Figure 5 Be the original grain state of embodiment 3, Figure 6 For the grain state of the core of the forging after the forging is heat-treated according to the above technical scheme, it can be seen that the grains are obviously uniform and refined after the forging is heat-treated by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com