Forging process for improving metallographic tissue of gear piece billet

A technology for metallographic structure and billet, which is applied in the field of forging technology for improving the metallographic structure of billets of gear parts, can solve the problems of lack of attention and high requirements, and achieve the effect of preventing structure inheritance, uniform composition of workpieces, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

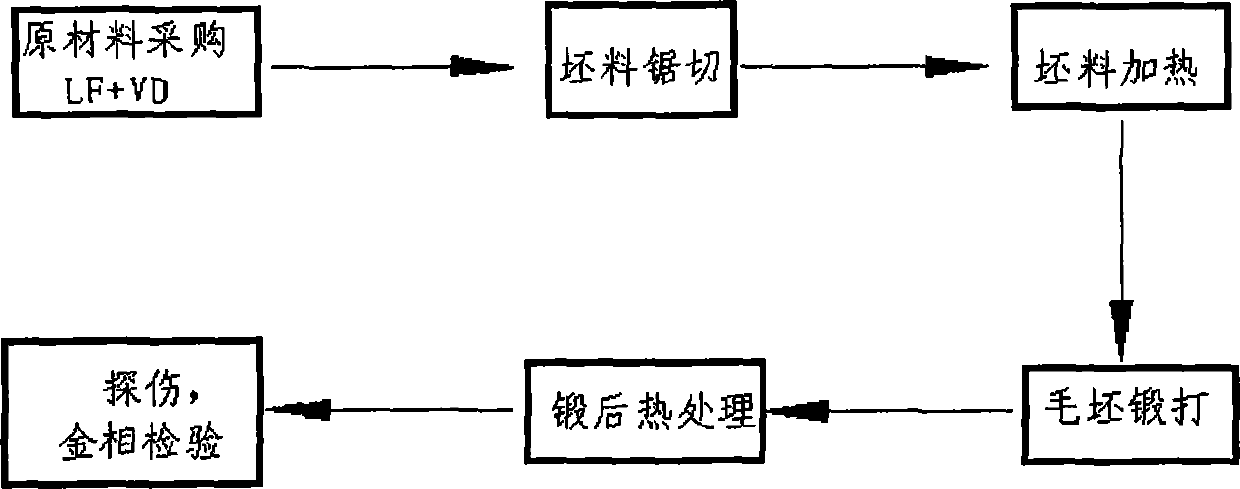

[0018] Such as figure 1 As shown, the present invention is a forging process for improving the metallographic structure of a gear billet, characterized in that the forging process includes the following steps:

[0019] The first step: select the raw material produced by LF+VD smelting as the billet, and cut off the riser which accounts for 25%-30% of the total raw material;

[0020] The second step: heating the blank obtained in the first step to 950-1200 degrees;

[0021] Step 3: Put the billet heated in the second step into the forging press for forging. During the whole forging process, according to the dendrite segregation characteristics of each bill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com