Manufacturing process of forging stock of steel forging piece for oil extraction equipment in deep sea

A manufacturing process and technology for steel forgings, which are applied in the field of manufacturing process of steel forging blanks for hydraulic cylinders of deep-sea oil production equipment, can solve the problems of inability to guarantee the quality of forgings after forming and forging, cracking of forging blank faces, edges and corners, and increasing forging difficulty. , to improve the malleability, ease the initiation, and slow down the cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Embodiment (process number B): the forging process described in the present invention;

[0041] Repeated example (process number C): repeat the forging process described in the present invention.

[0042] The specific steps of the comparative example (process number A) are as follows:

[0043] Step A①: Precipitation-hardening martensitic stainless steel 15-5PH is composed of carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel, copper and niobium, and its mass percentage is:

[0044] 0≤carbon≤0.07%, 0≤silicon≤1.00%, 0≤manganese≤1.00%, 0≤phosphorus≤0.035%, 0≤sulfur≤0.025%, 14.00%≤chromium≤15.50%, 4.00%≤nickel≤5.50% , 2.50≤copper≤4.00%, 0.15≤niobium≤0.45%,

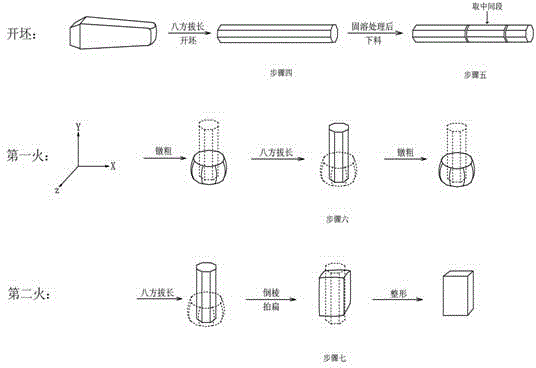

[0045] Step A②: Select a square ingot according to the size of the required structural parts, heat it into the furnace to 1150°C, and then open the billet (square cross-section) along the length direction of the steel ingot on the free forging hammer. The final forging temperature is 900°C. Complete the i...

Embodiment (

[0052] Embodiment (process number B), concrete steps are as follows:

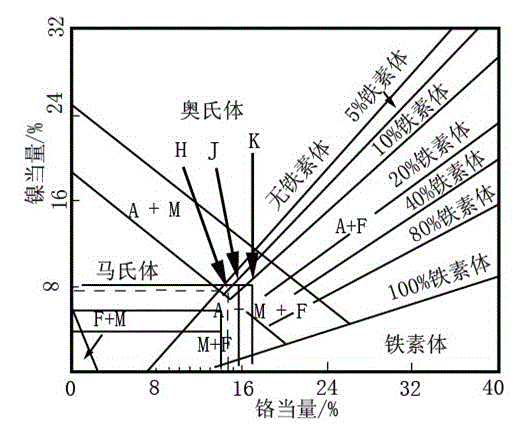

[0053] Step B①: Martensitic precipitation hardening stainless steel 15-5PH is composed of carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel, copper and niobium, and the mass percentage of its standard value is calculated by the formulas (1) and (2) respectively Calculation of the highest chromium equivalent and nickel equivalent corresponding to a ferrite content exceeding 10% (see figure 2 The position pointed by the arrow K in the middle),

[0054] Step B②: According to Schaeffler organization chart (see attached figure 2 ) The chemical composition of the optimally designed martensitic precipitation hardening stainless steel 15-5PH, its mass percentage is:

[0055] 0.04≤carbon≤0.07%, 0≤silicon≤0.60%, 0.80≤manganese≤1.00%, 0≤phosphorus≤0.035%, 0≤sulphur≤0.025%, 14.00%≤chromium≤14.50%, 5.00%≤nickel≤5.50% , 2.50≤copper≤4.00%, 0.15≤niobium≤0.25%,

[0056] Calculate the ferrite amount corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com