Purifying and refining method of carbetocin

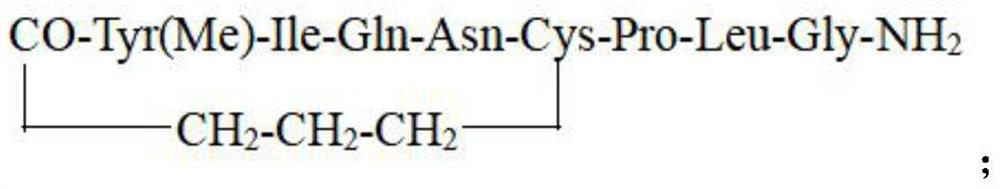

A carbetocin, purification and refining technology, applied in the field of drug purification and refining, can solve the problems of high single impurity content and low purification purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Weigh 10.0g of crude carbetocin, add it to 50ml of methyl tert-butyl ether, beat at room temperature for 2 hours, use a sand core funnel to filter, and dry the filter cake at 20-30°C for 2 hours to obtain carbetocin. Crude oxytocin I.

[0042] (2) Add the above-mentioned carbetocin crude product I to 50ml of 95% ethanol, beat at room temperature for 2 hours, use a sand core funnel to filter, and dry the filter cake at 20-30°C for 2 hours to obtain carbetocin crude product II .

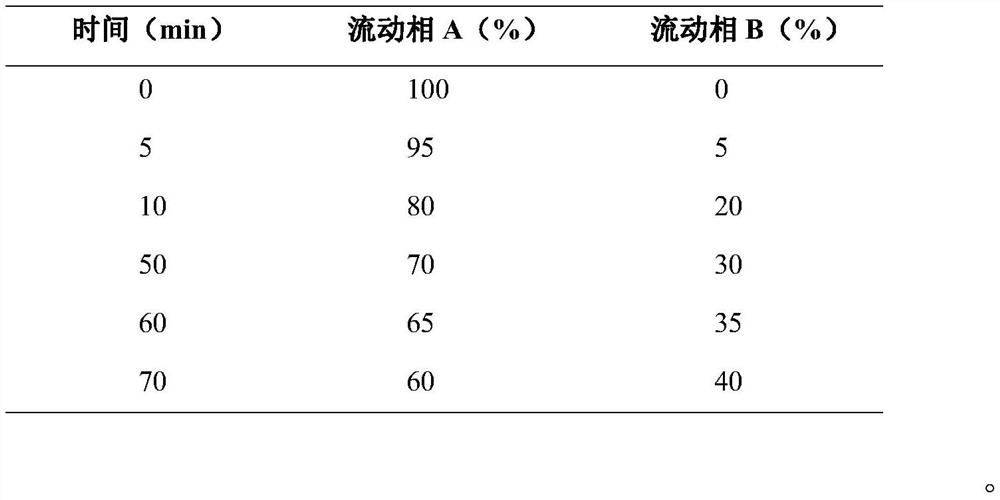

[0043] (3) Weigh 9.0g of carbetocin crude product II, add 270ml of 10% acetic acid solution, stir to dissolve, use reverse phase preparative high-performance liquid chromatography to purify, and collect carbetocin-containing elution for 25-35min. Fractions, the specific chromatographic conditions are as follows:

[0044] Equipment: Preparative HPLC, column diameter and length 60mm×300mm, packing C18

[0045] Mobile phase: A: 0.2% sodium acetate in water B: acetonitrile

[0046] Detection...

Embodiment 2

[0061] (1) Weigh 10.0 g of crude carbetocin, add it to 50 ml of methyl tert-butyl ether, beat at room temperature for 4 hours, use a sand core funnel to filter, and dry the filter cake at 20-30 ° C for 2 hours to obtain carbetocin Crude oxytocin I.

[0062] (2) Add the above-mentioned carbetocin crude product I to 50ml of 95% ethanol, beat at room temperature for 4 hours, use a sand core funnel to filter, and dry the filter cake at 20-30°C for 2 hours to obtain carbetocin crude product II .

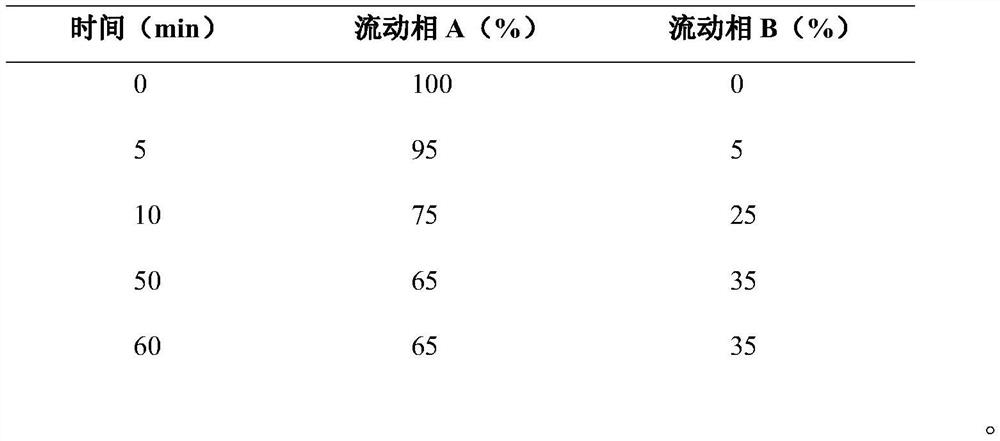

[0063] (3) Weigh 9.0g of carbetocin crude product II, add 270ml of 10% acetic acid solution, stir to dissolve, use reverse phase preparative high-performance liquid chromatography to purify, and collect carbetocin-containing elution for 25-35min. Fractions, the specific chromatographic conditions are as follows:

[0064] Equipment: Preparative HPLC, column diameter and length 60mm×300mm, packing C18

[0065] Mobile phase: A: 0.2% sodium acetate in water B: acetonitrile

[0066] Detect...

Embodiment 3

[0081] (1) Weigh 10.0 g of crude carbetocin, add it to 50 ml of methyl tert-butyl ether, beat at room temperature for 4 hours, use a sand core funnel to filter, and dry the filter cake at 20-30 ° C for 2 hours to obtain carbetocin Crude oxytocin I.

[0082] (2) Add the above-mentioned carbetocin crude product I to 50ml of 95% ethanol, beat at room temperature for 4 hours, use a sand core funnel to filter, and dry the filter cake at 20-30°C for 2 hours to obtain carbetocin crude product II .

[0083] (3) Weigh 9.0g of carbetocin crude product II, add 270ml of 10% acetic acid solution, stir to dissolve, use reverse phase preparative high-performance liquid chromatography to purify, and collect carbetocin-containing elution for 25-35min. Fractions, the specific chromatographic conditions are as follows:

[0084] Equipment: Preparative HPLC, column diameter and length 60mm×300mm, packing C18

[0085] Mobile phase: A: 0.2% sodium acetate in water B: acetonitrile

[0086] Detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com