Plastic floor

A technology of plastic floor and material, applied in the field of plastic floor, can solve the problems of consuming large trees, reducing the quality of composite floor, unfavorable environmental protection, etc., and achieving the effect of broad market prospect, novel structure and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

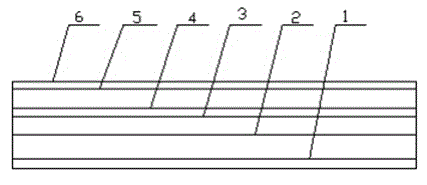

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] The present invention includes back layer 1, foam layer 2, glass layer 3, print layer 4, wear layer 5 and polyurethane layer 6, back layer 1, foam layer 2, glass layer 3, print layer 4, wear layer 5 and polyurethane layer 6 Connected sequentially from bottom to top, the material of the wear layer 5 is polyvinyl chloride, referred to as PVC, which greatly increases the wear resistance of the floor, thereby reducing the difficulty of maintenance and improving the service life. The material of the polyurethane layer 6 is Polyurethane, density 35-40kg / m 3 , the thermal conductivity is 0.018-0.024W / (m.k), good heat insulation, good waterproof, light texture, beautiful and practical.

[0014] The back layer 1 is made of wood particles with a particle size of less than 1.5 mm, which has good air permeability, is strong and practical. The material of the foam layer 2 incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com