Injection-production gas well variable-diameter well completion method and injection-production string

A technology of injection-production tubing string and gas injection-production, which is applied to wellbore/well components, drill pipe, casing, etc., to achieve the effect of reducing the construction cost and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] A method for variable-diameter completion of an injection-production gas well, comprising the following steps:

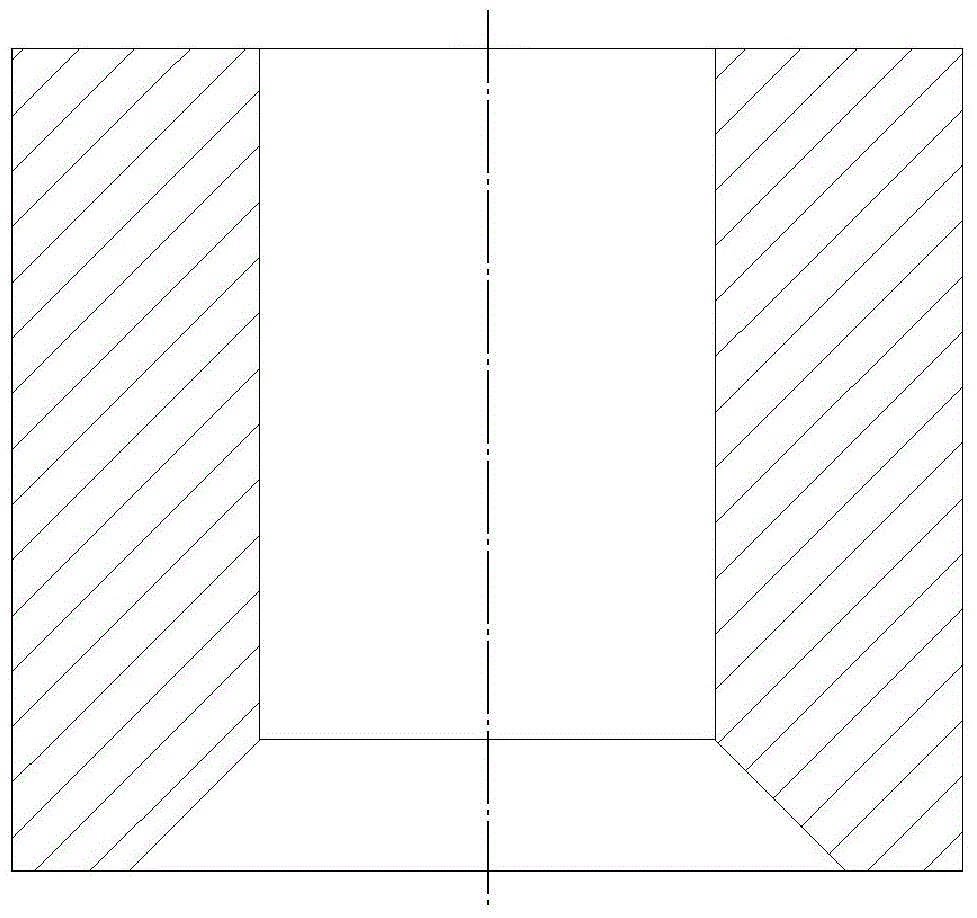

[0031] Step 1. Install the casing for well completion in the well. The casing includes an upper casing 1 and a lower casing 2 connected sequentially from top to bottom. The outer diameter of the upper casing 1 is larger than the outer diameter of the lower casing 2 , the flow area in the upper casing 1 is larger than the flow area in the lower casing 2;

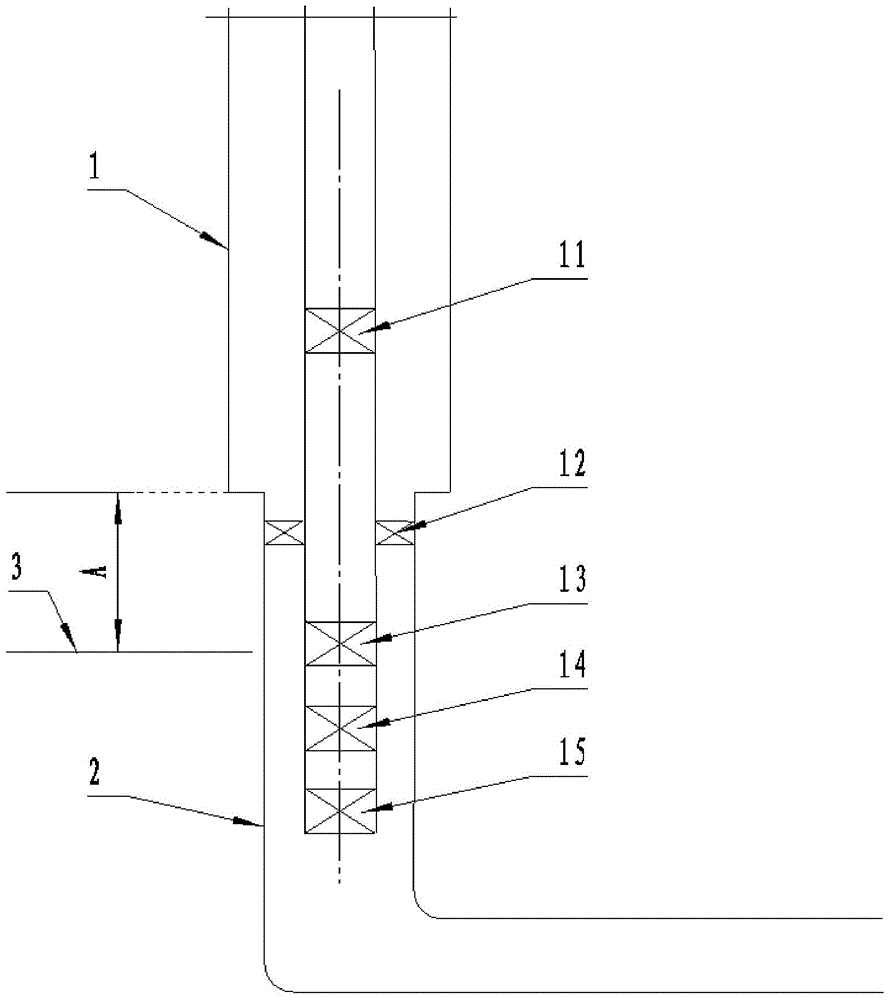

[0032] Step 2: Run a thinner first injection-production string into the casing during the gas drive production stage, such as figure 1 shown;

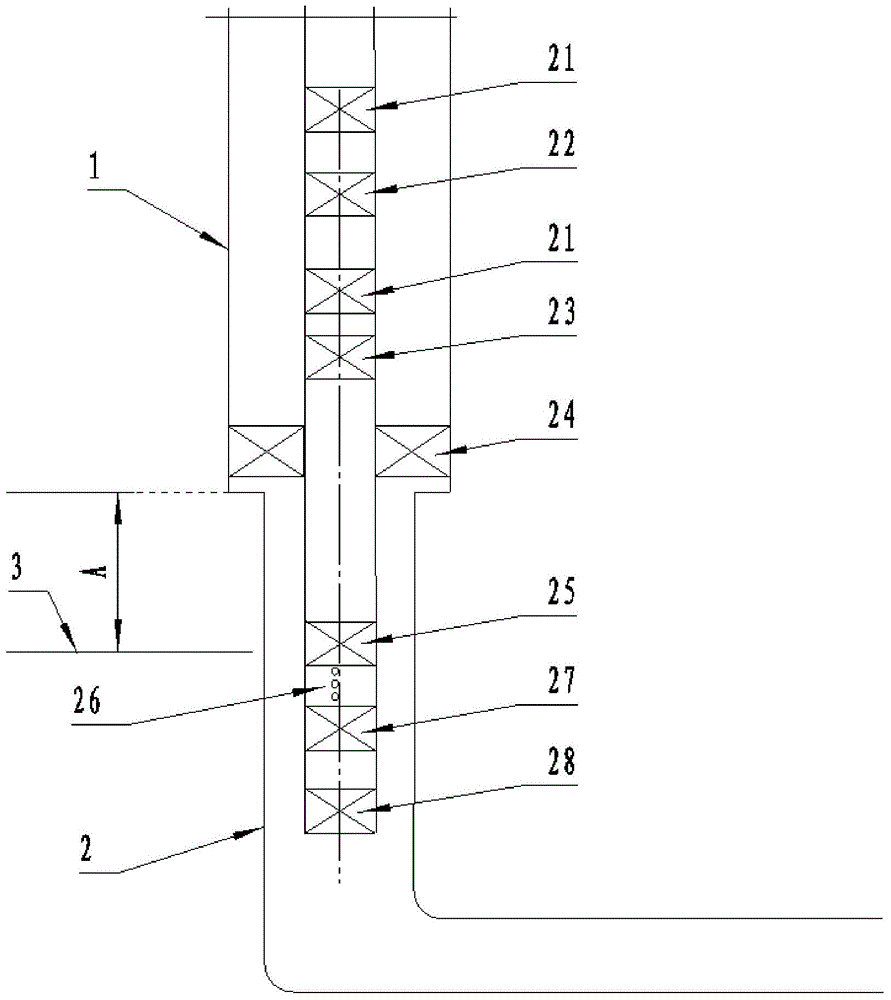

[0033] Step 3: Take out the first injection-production string from the casing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com