Heavy-load pneumatic diaphragm actuating mechanism

A pneumatic film and actuator technology, applied in engine components, mechanical equipment, valve details, etc., can solve the problems of inability to adjust the spring installation position, single action form of the actuator, low surface accuracy, etc., to achieve convenient warehouse management and flexible use. Strong performance, flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

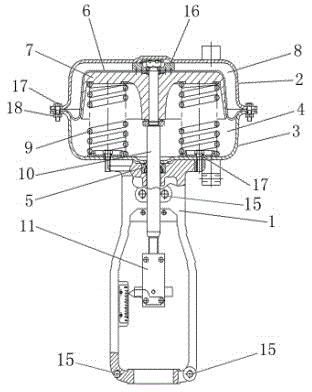

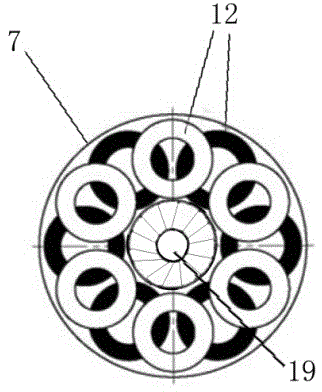

[0020] Such as figure 1 , 3 As shown, a heavy-duty pneumatic membrane actuator mainly includes a bracket 1, an upper membrane cover 2, a lower membrane cover 3, a diaphragm 6, a tray 7, a spring 9, a push rod 10 and a connecting half 11; The membrane cover 2 and the lower membrane cover 3 are fixedly connected together by bolts and nuts to form a hollow membrane chamber 4, and a guide bushing 5 is provided between the lower membrane cover 3 and the support 1, which are fixedly connected by bolts; the membrane chamber 4 A diaphragm 6, a tray 7 and a spring 9 are arranged inside, the upper diaphragm cover 2 forms a diaphragm air chamber 8 with the diaphragm 6 and the tray 7, the lower end of the spring 9 is fixed on the lower diaphragm cover 3, and its upper end abuts against the Tray 7, several springs 9 are provided between the lower membrane cover 3 and the tray 7 to form a spring chamber; corresponding holes 19 are provided in the middle of the upper membrane cover 2, the l...

Embodiment 2

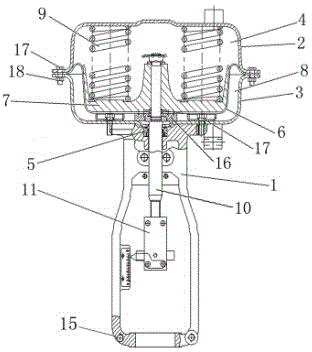

[0025] Such as figure 2 , 3 As shown, a heavy-duty pneumatic membrane actuator mainly includes a bracket 1, an upper membrane cover 2, a lower membrane cover 3, a diaphragm 6, a tray 7, a spring 9, a push rod 10 and a connecting half 11; The membrane cover 2 and the lower membrane cover 3 are fixedly connected together by bolts and nuts to form a hollow membrane chamber 4, and a guide bushing 5 is provided between the lower membrane cover 3 and the support 1, which are fixedly connected by bolts; the membrane chamber 4 A diaphragm 6, a tray 7 and a spring 9 are arranged inside, the lower diaphragm cover 3 forms a diaphragm air chamber 8 with the diaphragm 6 and the tray 7, the upper end of the spring 9 is fixed on the upper diaphragm cover 1, and its lower end abuts against Tray 7, several springs 9 are arranged between the upper membrane cover 2 and the tray 7 to form a spring chamber; corresponding holes 19 are provided in the middle of the upper membrane cover 2, the lowe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap