A three-degree-of-freedom large-stroke flexible nanopositioning platform

A technology of flexible positioning and large stroke, applied in the direction of machine/stand, supporting machine, mechanical equipment, etc., can solve the problems affecting positioning accuracy and control, compensation for difficult machining problems, affecting positioning accuracy, etc., to achieve compact structure and eliminate coupling. , Improve the effect of output displacement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below in conjunction with accompanying drawing:

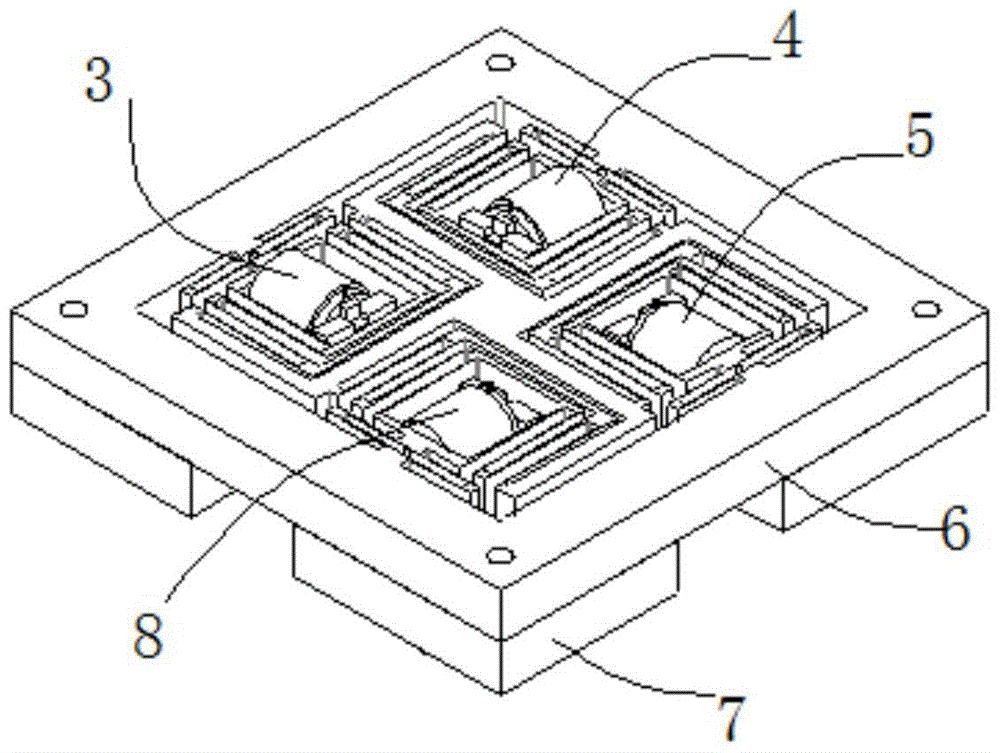

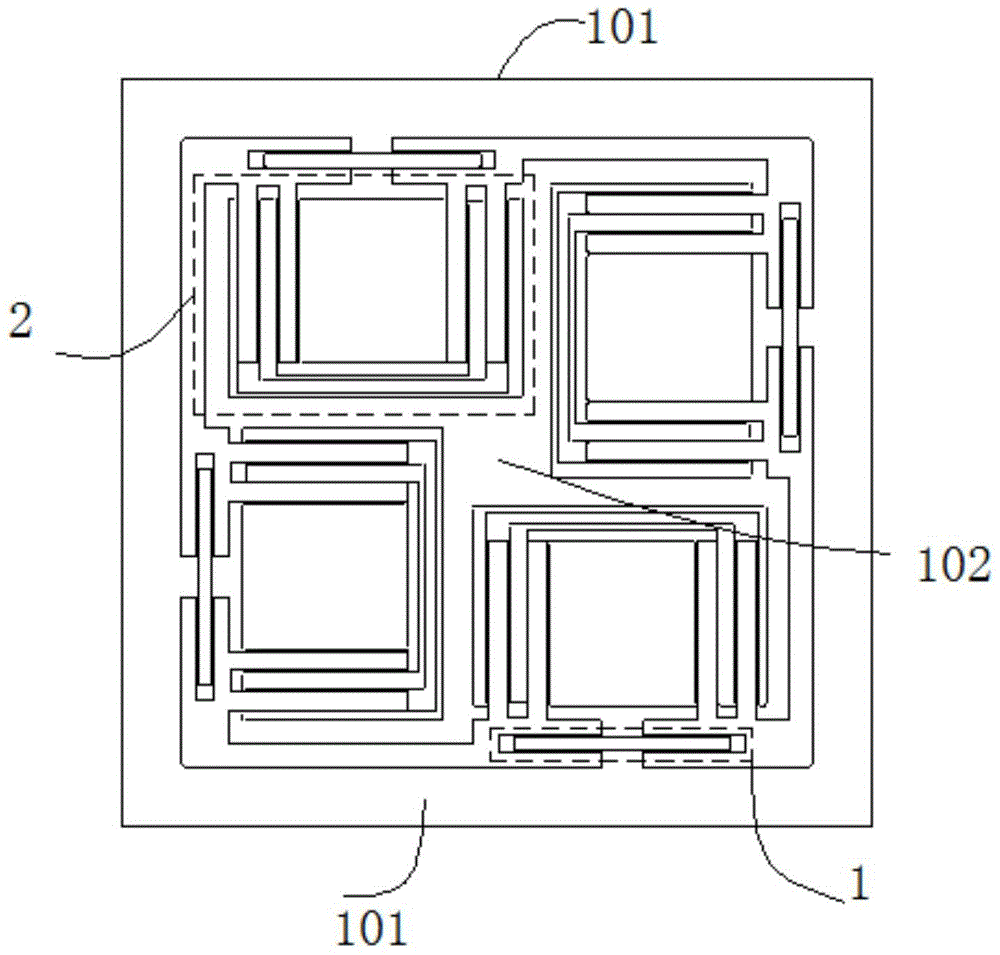

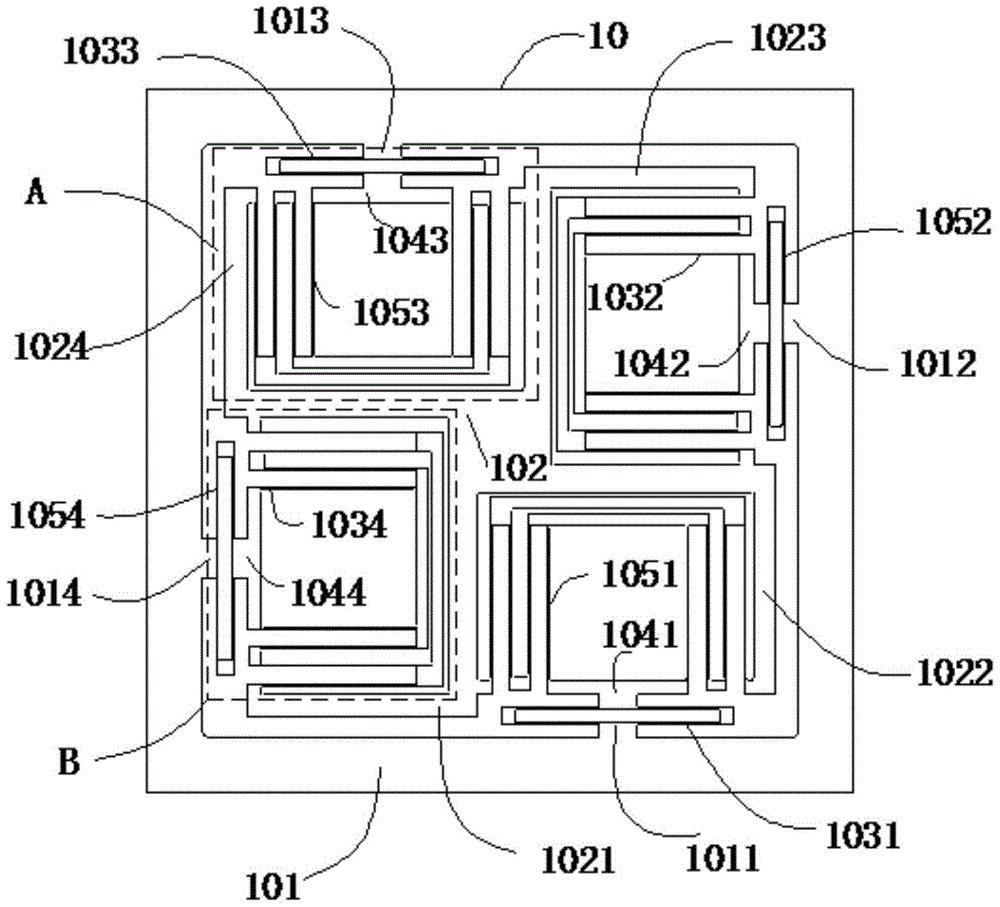

[0050] Refer below Figure 1-Figure 5 The XYθ three-degree-of-freedom large-stroke nano-flexible positioning platform 10 according to the embodiment of the present invention is described. In this example, the XYθ three-degree-of-freedom large-stroke nano-flexible positioning platform 10 includes:

[0051] The fixed base 7 includes the first connecting part of the fixed base, the second connecting part of the fixed base, the third connecting part of the fixed base, and the fourth connecting part of the fixed base; X-direction driver X1 (4), X-direction driver X2 (8) and Y To the driver Y1 (5), Y to the driver Y2 (3).

[0052] Base 101, base first connecting portion 1011, base second connecting portion 1012, base third connecting portion 1013, base fourth connecting portion 1014; terminal platform 102, terminal platform first connecting portion 1021, terminal platform The sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com