A surrounding pre-drilling device for combined fireworks group pots

A combination of fireworks and pre-drilling technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of reducing the success rate of insertion and lead wires, and achieve the effects of improving the success rate, uniform force, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

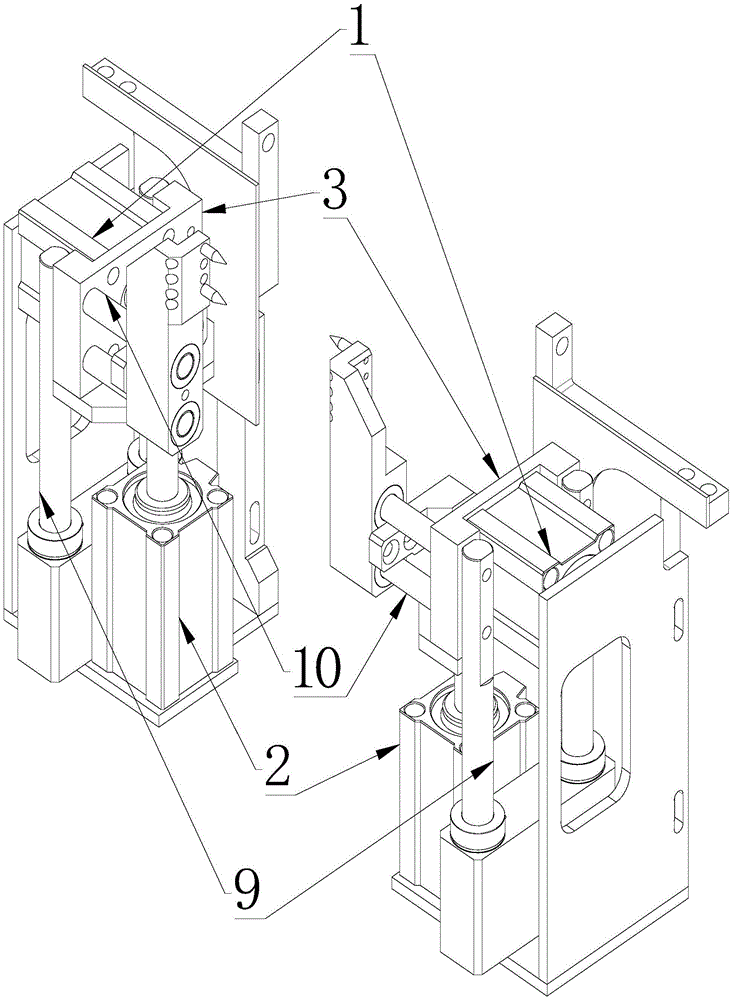

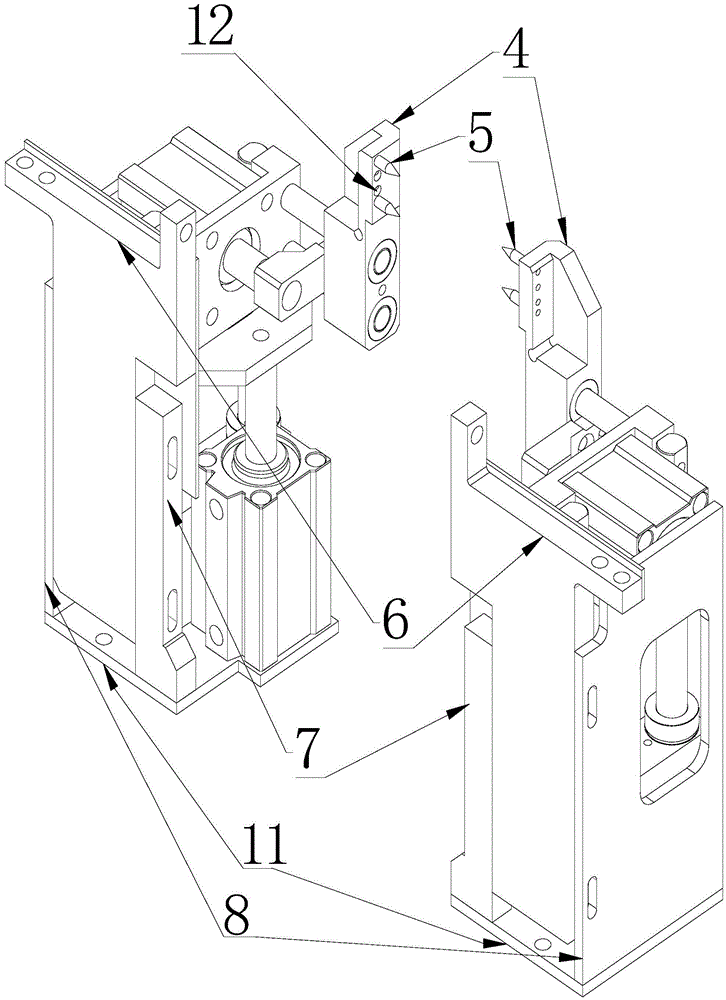

[0015] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the enclosing and pre-drilling device for combining the firework pots includes a first machine head and a second machine head arranged on opposite sides of the fireworks block as a whole, The first machine head and the second machine head have the same structure and are arranged symmetrically. The firework is block-shaped as a whole; the needle seat 4 of the socket circular needle 5 is installed on the left and right guide rods 10, and the left and right guide rods 10 are installed on the up and down movable substrate 3, and the circular needle driving cylinder 1 is installed on the up and down movable substrate 3, and the circular needle drives Cylinder 1 reciprocatingly drives needle base 4 of socket circular needle 5 in left and right direction; up and down movable substrate 3 is installed on upper and lower guide rod 9 , and substrate driving cylinder 2 reciprocates i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com