WZC1-430F thermocouple measurement compensation method under 36-45 DEG C

A compensation method, thermocouple technology, applied in measuring devices, measuring heat, thermometers with directly sensitive electrical/magnetic components, etc., can solve the accuracy error of controller data processing, temperature and actual temperature error, production process Influence and other issues to achieve the effect of enhancing measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] WZC1-430F thermocouple is a Cu50 thermocouple that can measure the temperature in the range of -50°C to 150°C. The measurement process is used in the range of -50°C to 150°C. The resistance is linearly proportional to the temperature, but in In practice, the relationship between resistance and temperature is not completely linear, and as the temperature increases, the linear relationship becomes worse and worse.

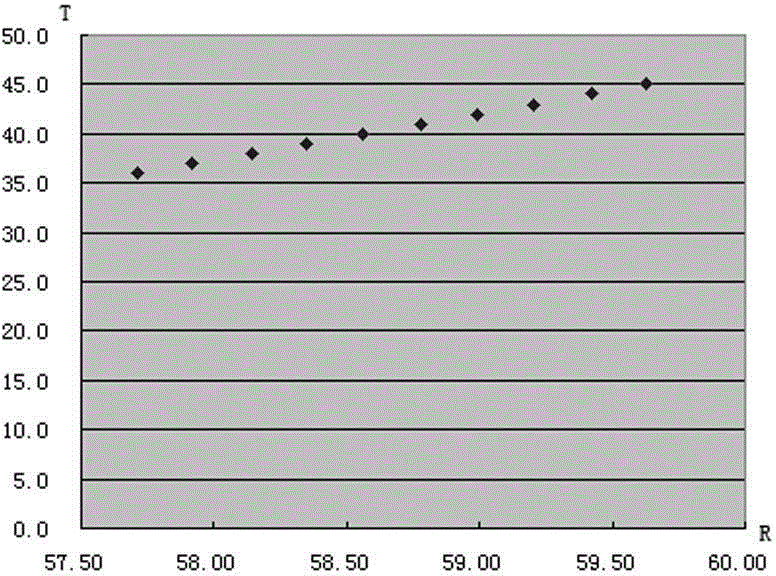

[0010] figure 1 It is the temperature-resistance schematic diagram of WZC1-430F thermocouple at 36°C-45°C. We found that the temperature and resistance in the temperature-resistance are proportional index relationship, It is a mathematical constant, which is the base number of the natural logarithm function. After calculation, the function value is obtained , R is the resistance value of WZC1-430F thermocouple, It is the corresponding temperature value. After many tests, it is found that the actual temperature of the WZC1-430F thermocouple is closest to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap