Circuit and method for measuring resistance of variable resistor

A resistance and variable technology, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring devices, etc., can solve the problems of low real-time requirements, low precision requirements, short capacitor charging and discharging time, etc. Contradictory effect of measurement accuracy and measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

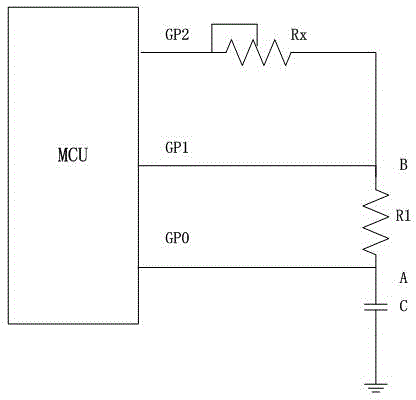

[0023] The invention provides a circuit for measuring the resistance value of a variable resistor, the schematic diagram of which is shown in image 3. The circuit includes a single-chip microcomputer, a capacitor C, a variable resistor to be measured Rx and a calibration resistor R1, one end of the capacitor C is connected to the first input and output port GP0 of the microcontroller, and the other end of the capacitor C is grounded; one end of the calibration resistor R1 A is connected to one end of the capacitor C, and the other end B of the calibration resistor R1 is connected to the second input and output port GP1 of the single-chip microcomputer; one end of the variable resistor Rx to be measured is connected to the third input and output port GP2 of the single-chip microcomputer, to be The other end of the measuring variable resistor Rx is connected to the other end B of the calibration resistor. Since the measurement accuracy of the variable resistor to be tested is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com