Chemical dry etching machine equipped with pumping pipeline pressure monitoring device

A chemical dry method and monitoring device technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of APC component failure, isolation valve failure, dry pump efficiency attenuation, etc., and achieve the effect of eliminating failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

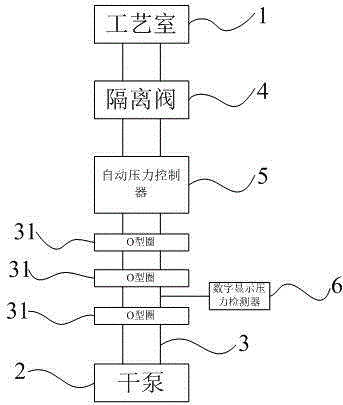

[0017] Such as figure 1 As shown, a chemical dry etching machine equipped with a pumping pipeline pressure monitoring device includes a process chamber 1 connected in sequence through a pumping pipeline 3, an isolation valve 4, an automatic pressure controller 5 and a dry pump 2; the automatic pressure control A commercially available digital pressure detector 6 is arranged between the device 5 and the dry pump 2; the digital pressure detector 6 is arranged outside the pumping pipeline 3; the digital pressure detector 6 is used to detect the pressure change of the pumping pipeline 3. A plurality of O-rings 31 are evenly distributed on the outside of the pumping pipeline 3 .

[0018] Specific application: When the process room encounters "exhaust cannot be completed within the set time", we can block the port bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com