DIN type intermodulation waterproof electric bridge

A waterproof electric bridge and high intermodulation technology, which is applied in the direction of circuits, electrical components, waveguide devices, etc., can solve the problems of insufficient selling price and low cost, and it is difficult to withstand high power, so as to achieve the effect of reducing production cost and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

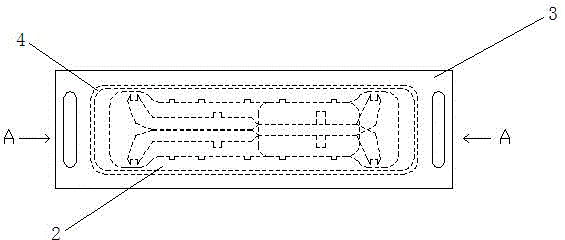

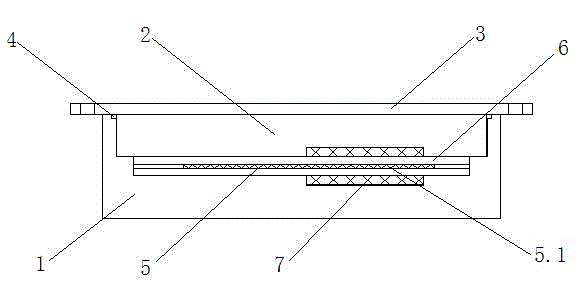

[0014] refer to Figure 1-2 , a DIN type high intermodulation waterproof electric bridge, which consists of a lower cavity 1, an inner cover 2, and an outer cover 3, an inner cover 2 is installed above the lower cavity 1, and an outer cover is arranged above the inner cover 2 plate 3.

[0015] The inner cover 2 is aligned with the upper surface of the lower cavity 1, and there is a waterproof groove 4 between the inner cover 2 and the lower cavity 1.

[0016] The lower cavity 1 is provided with a microstrip line 5, and the upper and lower sides of the microstrip line 5 are respectively provided with a dielectric plate 6, and the outer surface of the dielectric plate 6 is respectively provided with an additional dielectric plate 7, and the microstrip line 5 includes There is a first-order coupling zone 5.1,

[0017] The additional dielectric plate 7 is arranged on the outer layer of the upper and lower dielectric plates 6 at the position of the primary coupling area 5.1 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com