Power distribution cabinet provided with positioning protrusion

A technology for power distribution cabinets and cabinets is applied in the field of power distribution cabinets with protruding positioning, which can solve the problems of noise, hidden dangers, easy to cause impact force, etc., and achieve the effects of convenient use, reliable operation, and impact avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

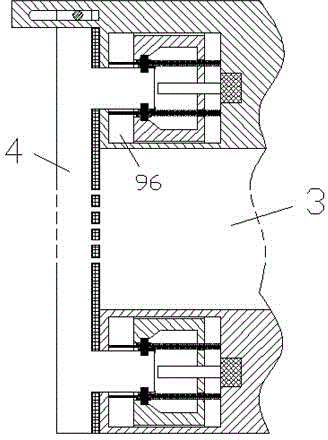

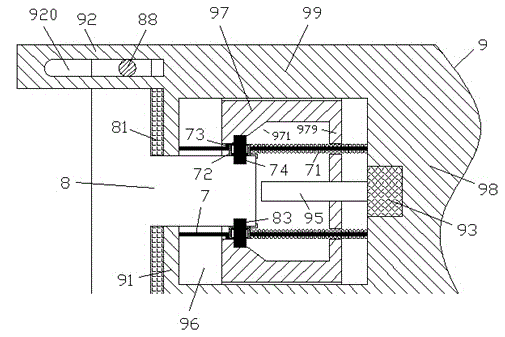

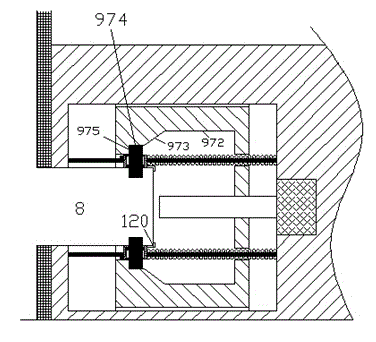

[0011] Combine below Figure 1-4 The present invention will be described in detail.

[0012] According to the embodiment, the power distribution cabinet provided with positioning protrusions includes a cabinet body 3 with a locking socket device 9 at the frame and a door panel 4 with a cylindrical locking protruding plug 8 at the corresponding edge, the locking The protruding plug 8 is intended to be inserted into a cavity 96 of said locking socket means 9 comprising an end wall 91 , a lateral side wall 99 and a body 98 opposite said end wall 91 Thus, the cavity 96 is enclosed, and the side of the door panel 4 facing the cabinet body 3 is provided with an elastic sealing layer 81 for joining with the outside of the end wall 91, and the cavity 96 is provided with a The inner side of the end wall 91 and a plurality of guide column bars 7 fixedly connected with the body 98, the guide column bars 7 slide and carry a locking slider assembly 72, and the locking slider assembly 72 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com