Wing and application thereof

A technology of airfoil and spar, applied in wing and its application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

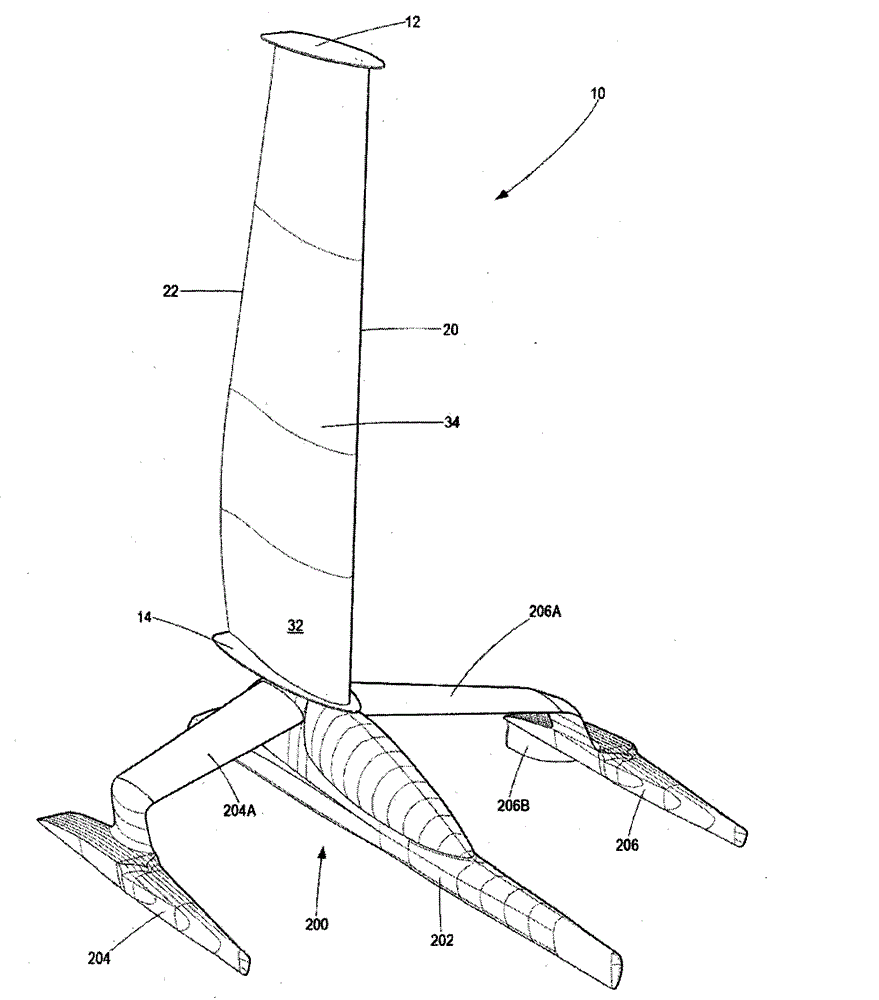

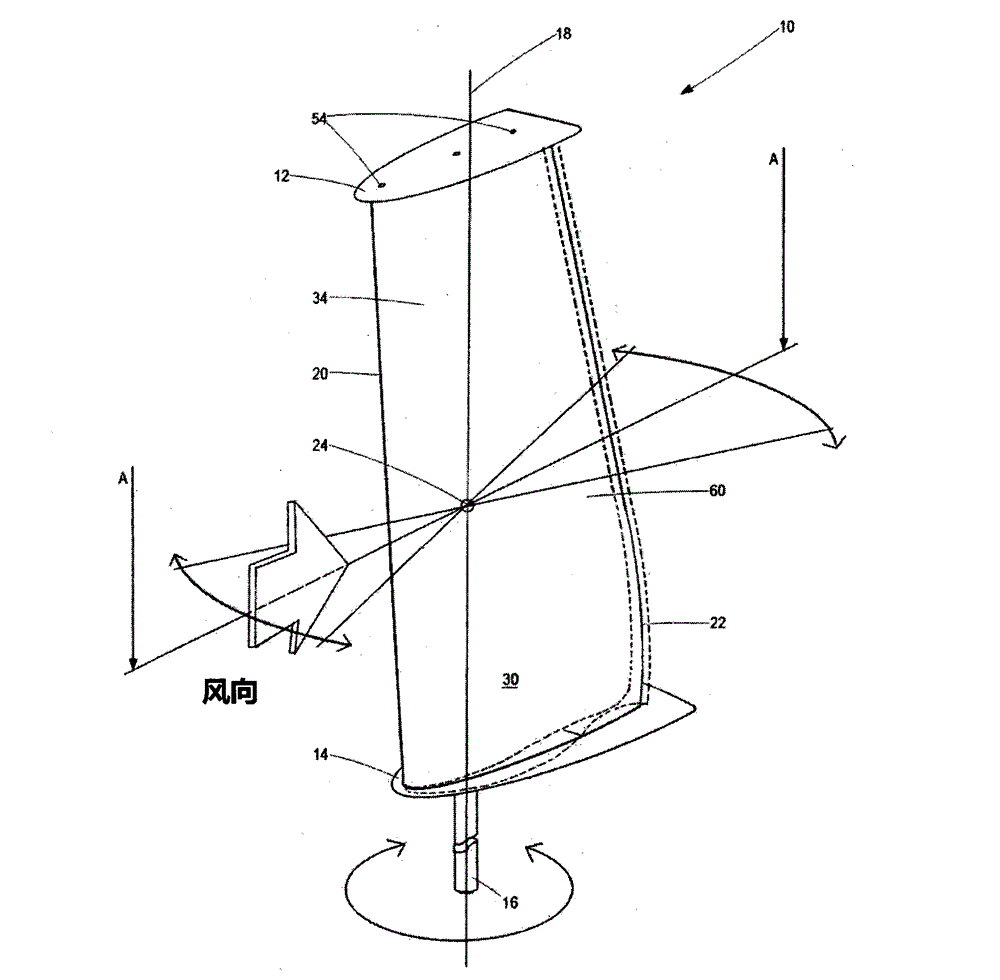

[0140] Wings according to the present disclosure including devices, systems, and methods may find application in a variety of applications. In order to provide a detailed description of the invention, the wing will be described with reference to its application as a wingsail applied to a watercraft 200 , indicated generally by the reference numeral 10 in the drawings.

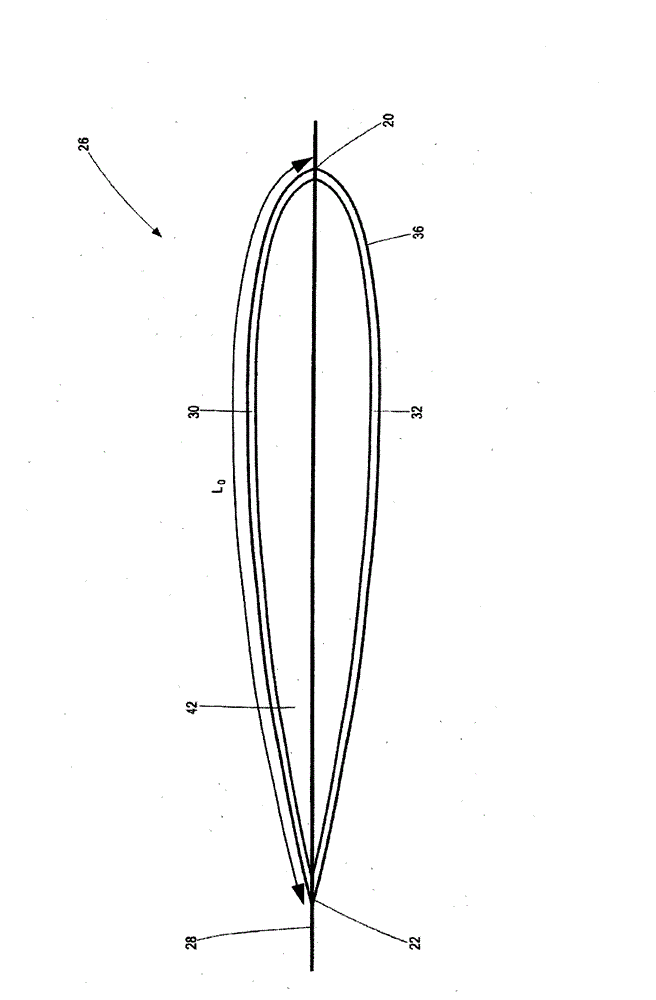

[0141] refer to figure 1 and figure 2 , the sail 10 is supported between a first end plate 12 and a second end plate 14 generally located at the operative upper and lower wing tips of the wing sail 10, respectively, the first end plate and the second end plate for An escape of the air flow from the high pressure to the low pressure side over the tip of the wing sail 10 and / or into the hollow wing sail 10 is prevented, so that the generation of eddies is prevented as much as possible. A gap (not shown) is defined between the wing sail 10 and the end plates 12 , 14 , typically closed by a gasket or seal, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com