Method for stabilizing the friction coefficient gradient of a clutch in a motor vehicle

A technology of motor vehicle and friction coefficient, applied in the direction of clutch, mechanical equipment, etc., can solve the problem of increased vibration tendency of motor vehicle, and achieve the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

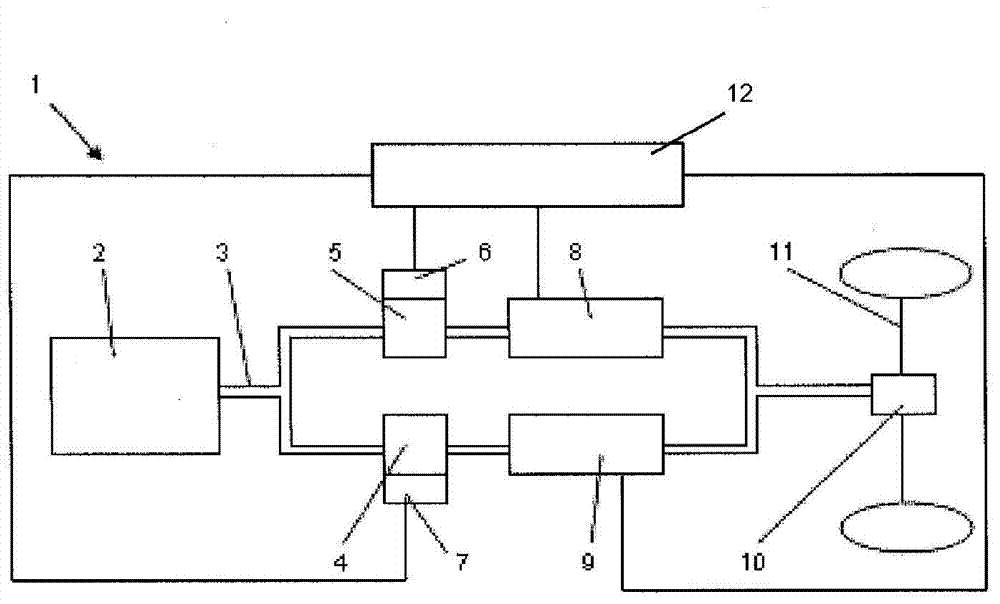

[0018] figure 1 A schematic diagram of a drive train 1 of a motor vehicle with a dual clutch transmission is shown. In this case, a drive unit 2 , for example an internal combustion engine, is connected via a shaft 3 to a dual clutch transmission, which is described in detail below.

[0019] A dual clutch transmission consists of two subsystems. The first sub-train here has a first sub-transmission clutch 4 , which leads to a first sub-drive train 9 . Drive unit 2 in the form of an internal combustion engine is also connected to a second sub-train, which includes a second sub-transmission clutch 5 , which leads to a second sub-drive train 8 . The two drive train sub-trains 8 , 9 are led via an axle differential 10 to a transaxle 11 of the motor vehicle.

[0020] The different gears are separated in the sub-drive trains 8 , 9 . Thus, the first power train sub 9 has odd gears, eg 1, 3, 5, while the second power train sub 8 has even gears, eg 2, 4, 6. When changing from one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com