Mineral crushing magnetic separator

A technology for magnetic separation and mineral separation. It is applied in the fields of magnetic separation, solid separation, grain processing, etc. It can solve the problems of inability to guarantee the separation effect and consume a lot of time, and achieve a high degree of automation, effective separation operation, and good separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

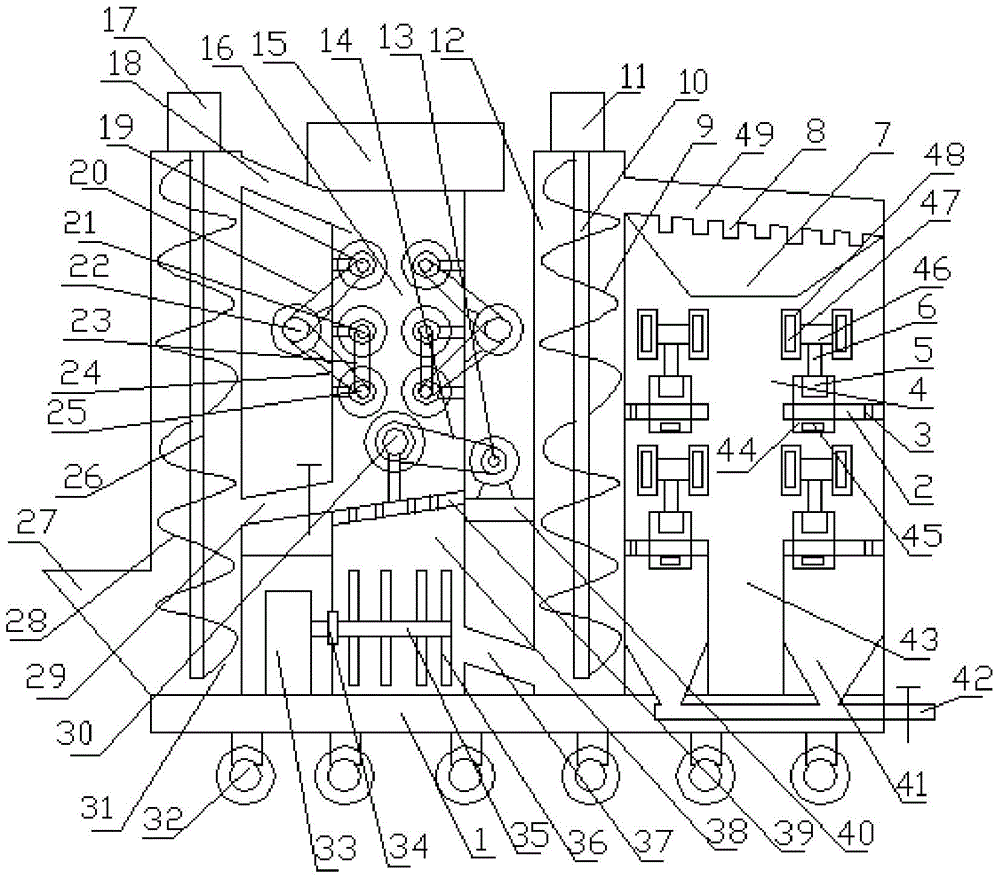

[0018] Such as figure 1 The mineral crushing and magnetic separation separator shown includes a base plate 1, a left lifting chamber 31 is arranged on the left side of the upper part of the base plate 1, a lower feeding chamber 27 is connected to the left lower part of the left lifting chamber 31, and a lower feeding chamber 27 is connected to the left upper part of the left lifting chamber 31. Connected with a feeding pipe 18, the right side of the feeding pipe 18 is connected with a crushing chamber 16, the upper part of the crushing chamber 16 is connected with an upper feeding chamber 15, and the lower part of the left side of the crushing chamber 16 is connected with a return pipe 29, and the left side of the return pipe 29 Connected with the right side of the left lifting chamber 31, the bottom of the crushing chamber 16 is provided with a filter plate 39, the bottom of the filter plate 39 is provided with a stirring chamber 38, the right side of the stirring chamber 38 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com