Die special for single-column flatting mill

A flattening machine and single-column technology, which is applied in the field of special molds for single-column flattening machines, can solve problems such as inconsistency in the flattening height of aluminum tubes, and achieve high flatness, convenient use, and good height consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

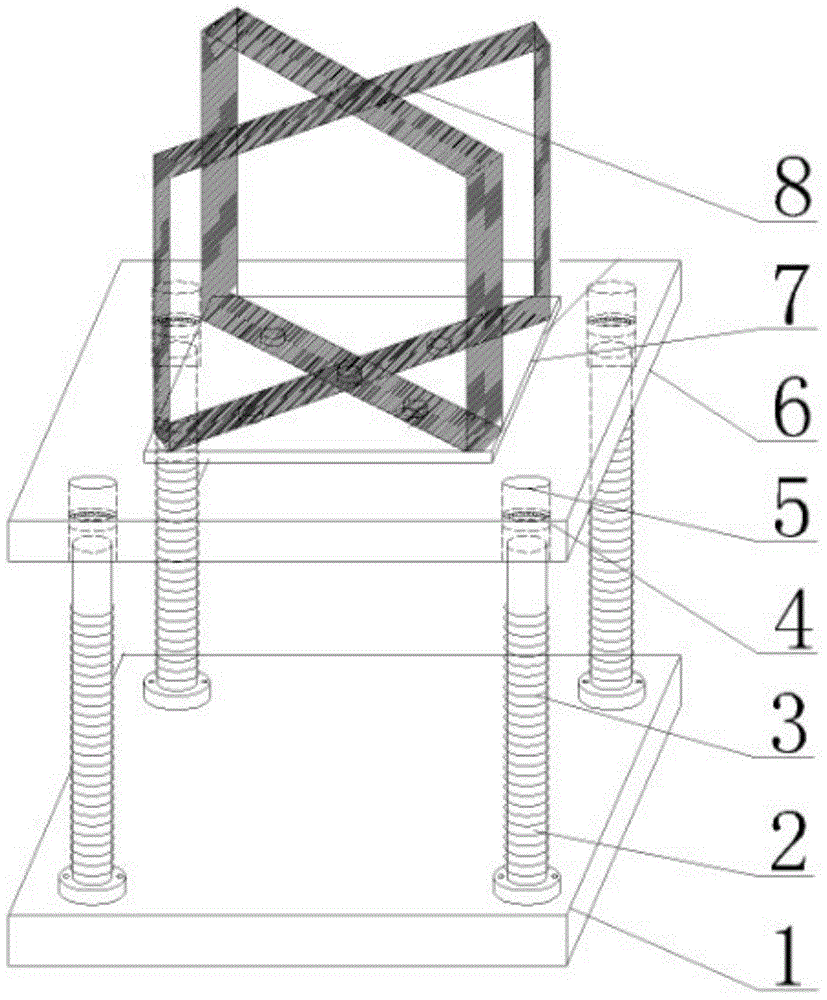

[0014] See the accompanying drawings: a special mold for a single-column flattening machine, including a lower formwork 1, an upper formwork 6, a small square plate 7 and a cross force equalization frame 8, and the four corners of the lower formwork 1 are equipped with bolts to fix guide rods 2, The guide rod 2 is covered with a spring 3, and the four corners of the upper template 6 are provided with through holes 5, and the through hole 5 is embedded with a collar 4 with balls. The inner diameter of the collar 4 is the diameter of the guide rod 2 plus 0.2mm. The square plate 7 is fixed on the upper formwork 6 by bolts, and the cross force balance frame 8 is connected with the small square plate 7 and the upper formwork 6 as a whole by bolts. Preferably, the lower template 1 is a solid steel plate with a thickness of not less than 40mm, made of Cr12 alloy steel, with a Rockwell hardness of not less than 45HRC, the surface finish opposite to the upper template 6 meets the nation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com