A new type of block feeding and lifting device and method for a frame saw machine

A frame-type, block technology, which is applied in the field of new type block feeding and lifting devices for frame-type saw machines, can solve the problems of increasing the difficulty of the structural layout of the saw machine, aggravating wear, and difficult replacement, so as to achieve the overall compact structure of the equipment and the The effect of reliable relationship and reasonable structure arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

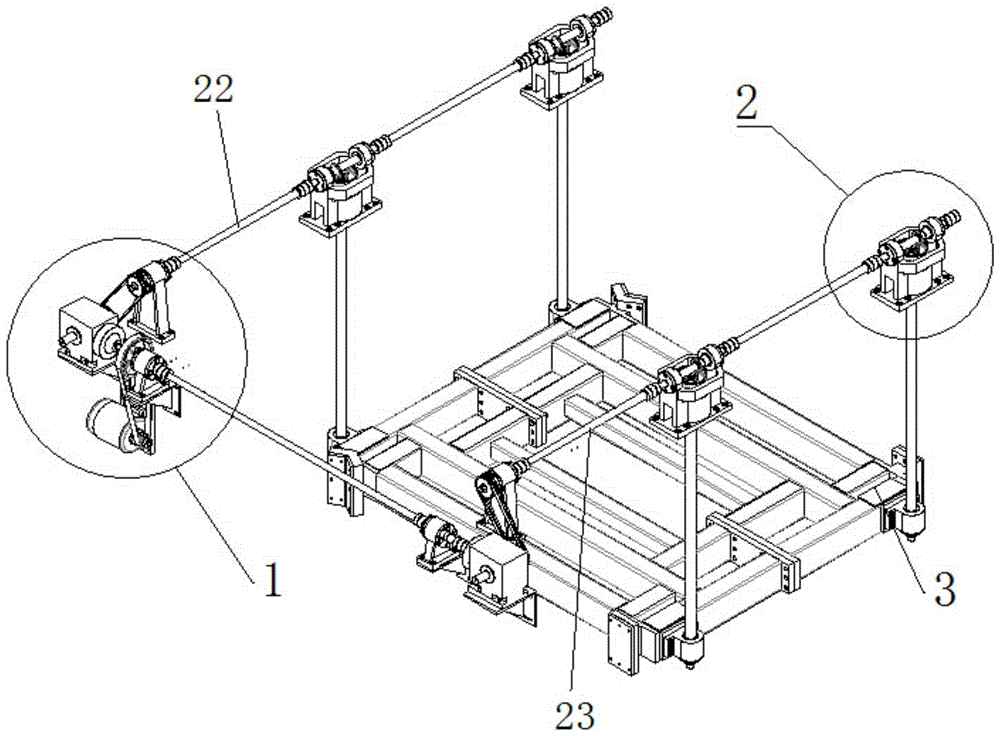

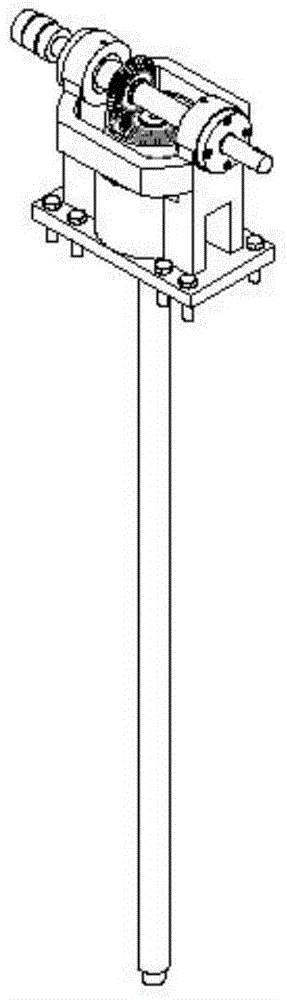

[0031] Such as figure 1 As shown, a new type of block feeding and lifting device for a frame saw machine is composed of a power transmission mechanism 1, a feeding lifting mechanism 2, and a lifting table mechanism 3. The power transmission mechanism 1 provides driving force and motion for the whole device and transmits it to the feed lifting mechanism 2; Transfer to the lifting table mechanism 3 to realize the lifting function of the lifting table mechanism 3; the main function of the lifting table mechanism 3 is to carry stone blocks and ensure the stability of the stone blocks during the lifting process.

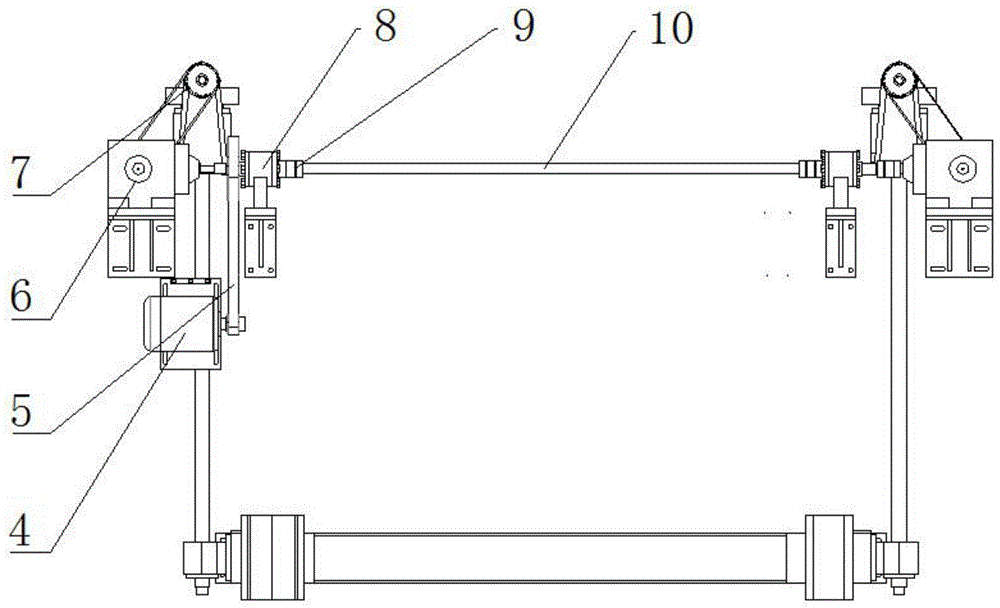

[0032] The power transmission mechanism 1 mainly includes a motor 4 , a synchronous belt transmission assembly 5 , a reducer 6 , a chain transmission assembly 7 , a support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com