A rolling method for improving surface wrinkling resistance of ferritic stainless steel

A stainless steel wrinkle resistance technology, which is applied in the field of rolling to improve wrinkle resistance on the surface of ferritic stainless steel, can solve the problems of reducing production efficiency, increasing rolling process and rolling rhythm time, etc. The effect of increased shear deformation band and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

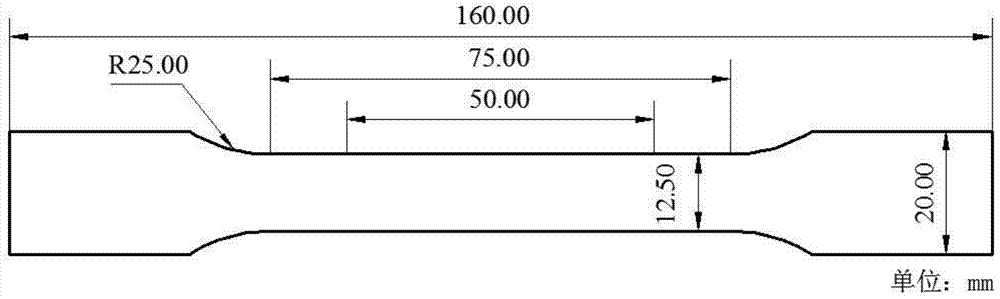

[0026] A hot-rolled annealed plate with a thickness of 2.87 mm was selected, and then the test plate was cold-rolled on a two-roll mill.

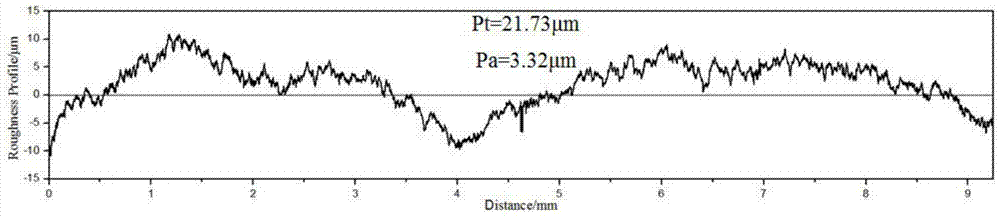

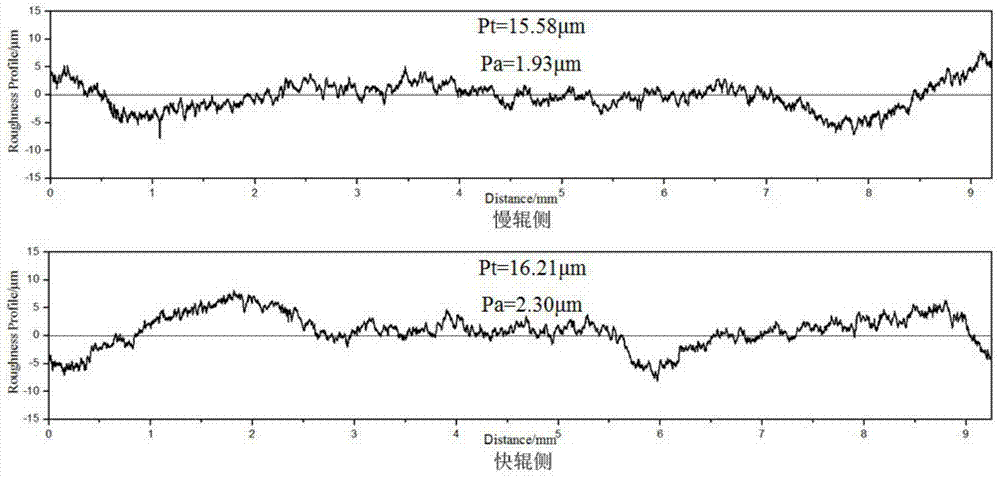

[0027] In order to achieve the purpose of asynchronous rolling, different roll diameter configurations are used in cold rolling to achieve asynchronous rolling. At the same time, a group of synchronous rolling with the same roll diameter ratio was selected for comparison. The specific method and cold rolling process of the rolls are shown in Table 1.

[0028] Table 1

[0029]

Simultaneous rolling

Speed ratio 1.11

Speed ratio 1.20

Roll diameter configuration (mm / mm)

100 / 100

90 / 100

100 / 120

Original thickness (mm)

2.87

2.87

2.87

Final rolling thickness (mm)

0.57

0.60

0.57

Reduction rate

80.1%

79.1%

80.1%

[0030] The above-mentioned cold-rolled sheets of different processes were annealed, the annealing temperature was 880° C., and the ann...

Embodiment 2

[0034] Embodiment 2: A rolling method for improving wrinkling resistance on the surface of ferritic stainless steel, which is suitable for adding Nb and Ti stabilizing elements containing 16%-22% of Cr content and ultra-pure stainless steel with C+N content≤0.02%. Ferritic stainless steel, including the following steps:

[0035] Step 1, carrying out hot rolling treatment to cast slab;

[0036] Step 2, carrying out annealing and pickling treatment to the hot-rolled plate;

[0037] Step 3, cold rolling by asynchronous rolling method: the hot-rolled annealed and pickled plate is subjected to asynchronous rolling and cold rolling, the asynchronous rolling speed ratio is between: 1.50, and the total rolling reduction is 90%;

[0038] Step 4, cold rolling and annealing: the steel plate obtained by asynchronous rolling and cold rolling is annealed, the annealing temperature is 1000° C., and the annealing time is 1 min.

Embodiment 3

[0039] Embodiment 3: A rolling method for improving wrinkling resistance on the surface of ferritic stainless steel, which is suitable for adding Nb and Ti stabilizing elements containing 16%-22% of Cr and ultra-pure stainless steel with C+N content≤0.02%. Ferritic stainless steel, including the following steps:

[0040] Step 1, carrying out hot rolling treatment to cast slab;

[0041] Step 2, carrying out annealing and pickling treatment to the hot-rolled plate;

[0042] Step 3, cold rolling by asynchronous rolling method: the hot-rolled annealed and pickled plate is subjected to asynchronous rolling and cold rolling, the asynchronous rolling speed ratio is between: 1.05, and the total rolling reduction is 75%;

[0043] Step 4, cold rolling and annealing: the steel plate obtained by asynchronous rolling and cold rolling is annealed, the annealing temperature is 840° C., and the annealing time is 4 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com