Rolling method for enhancing ferritic stainless steel surface wrinkling resistance

A stainless steel and wrinkle resistance technology is applied in the rolling field to improve the surface wrinkle resistance of ferritic stainless steel. Improved wrinkle height and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

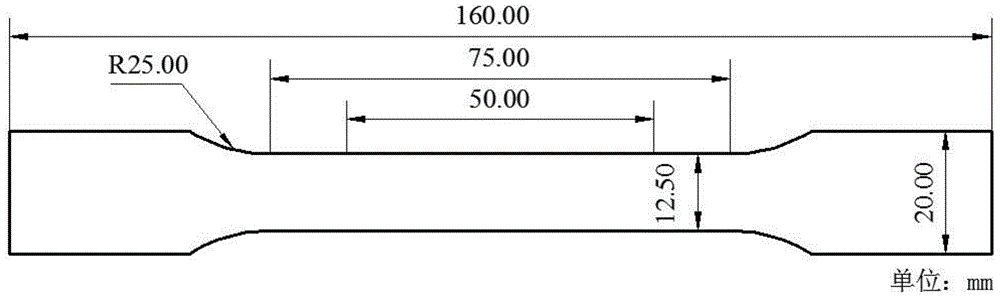

[0026] A hot-rolled annealed plate with a thickness of 2.87 mm was selected, and then the test plate was cold-rolled on a two-roll mill.

[0027] In order to achieve the purpose of asynchronous rolling, different roll diameter configurations are used in cold rolling to achieve asynchronous rolling. At the same time, a group of synchronous rolling with the same roll diameter ratio was selected for comparison. The specific method and cold rolling process of the rolls are shown in Table 1.

[0028] Table 1

[0029] Simultaneous rolling Speed ratio 1.11 Speed ratio 1.20 Roll diameter configuration (mm / mm) 100 / 100 90 / 100 100 / 120 Original thickness (mm) 2.87 2.87 2.87 Final rolling thickness (mm) 0.57 0.60 0.57 Reduction rate 80.1% 79.1% 80.1%

[0030] The above-mentioned cold-rolled sheets of different processes were annealed, the annealing temperature was 880° C., and the annealing time was 2 minutes.

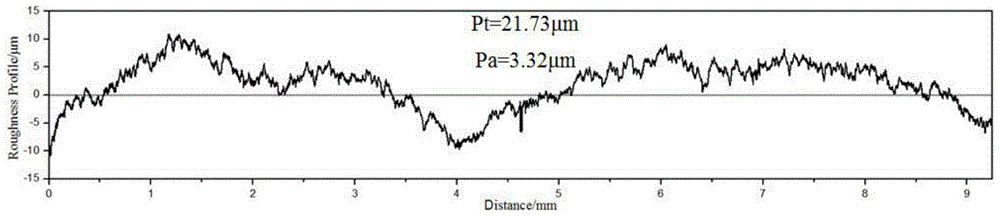

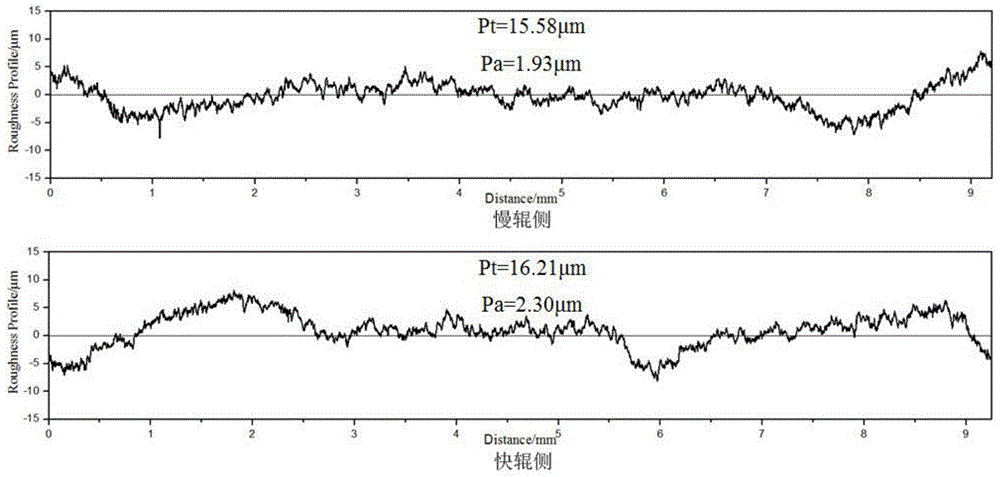

[0031] Annealed sh...

Embodiment 2

[0034] Embodiment 2: A rolling method for improving wrinkling resistance on the surface of ferritic stainless steel, which is suitable for adding Nb and Ti stabilizing elements containing 16%-22% of Cr content and ultra-pure stainless steel with C+N content≤0.02%. Ferritic stainless steel, including the following steps:

[0035] Step 1, carrying out hot rolling treatment to cast slab;

[0036] Step 2, carrying out annealing and pickling treatment to the hot-rolled plate;

[0037] Step 3, cold rolling by asynchronous rolling method: the hot-rolled annealed and pickled plate is subjected to asynchronous rolling and cold rolling, the asynchronous rolling speed ratio is between: 1.50, and the total rolling reduction is 90%;

[0038] Step 4, cold rolling and annealing: the steel plate obtained by asynchronous rolling and cold rolling is subjected to annealing treatment, the annealing temperature is 1000° C., and the annealing time is 1 min.

Embodiment 3

[0039] Embodiment 3: A rolling method for improving wrinkling resistance on the surface of ferritic stainless steel, which is suitable for adding Nb and Ti stabilizing elements containing 16%-22% of Cr and ultra-pure stainless steel with C+N content≤0.02%. Ferritic stainless steel, including the following steps:

[0040] Step 1, carrying out hot rolling treatment to cast slab;

[0041] Step 2, carrying out annealing and pickling treatment to the hot-rolled plate;

[0042] Step 3, cold rolling by asynchronous rolling method: the hot-rolled annealed and pickled plate is subjected to asynchronous rolling and cold rolling, the asynchronous rolling speed ratio is between: 1.05, and the total rolling reduction is 75%;

[0043] Step 4, cold rolling and annealing: the steel plate obtained by asynchronous rolling and cold rolling is annealed, the annealing temperature is 840° C., and the annealing time is 4 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com