Concrete reinforcing frame combined formwork

A technology of combined templates and reinforced frames, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of high labor costs, high consumption of turnover materials, uneconomical and other problems, and achieve overall Rigidity, limit of upper and lower openings and size control of diagonal, strong integrity, prevent mold expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

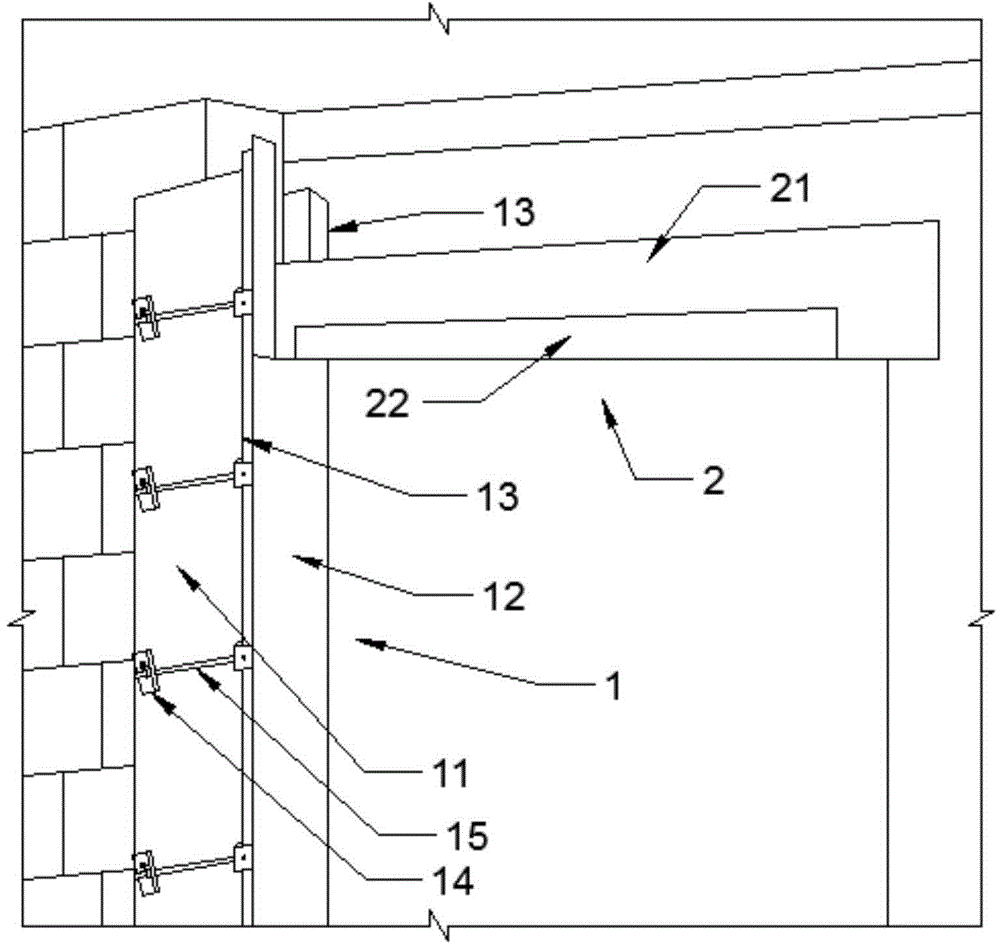

[0017] Embodiment: a kind of concrete reinforced frame composite template, such as figure 1 As shown, it is composed of a side column formwork 1 and a lintel formwork 2, and the lintel formwork is placed on the upper end of the side column formwork.

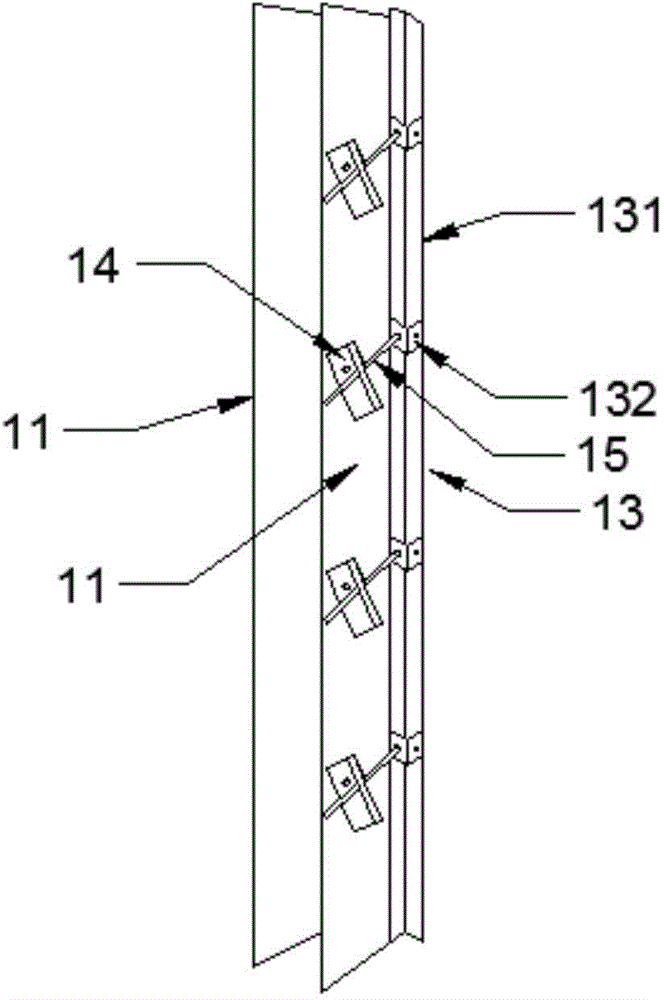

[0018] Such as figure 1 and figure 2 As shown, the side column formwork 1 is composed of two longitudinal first side formworks 11 and a longitudinal head plate 12 connected by two vertical corrugations 13, and the two first side formworks are located on both sides of the head plate to form a section It is a U-shaped side column formwork, the vertical corrugation 13 has a body 131 made of equilateral angle steel and a plurality of L-shaped steel sheets welded to the body, the plurality of L-shaped steel sheets are distributed longitudinally at intervals, and the L-shaped steel sheets and their locations The body part of the body constitutes a square pipe section 132, the position of the square pipe section corresponds to the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com