Sound-muffling smoke exhauster

A range hood and noise reduction technology, applied in the field of range hoods, can solve problems such as turbulent noise of centrifugal fans, and achieve the effects of reducing noise, improving mute function, and ensuring the quality of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

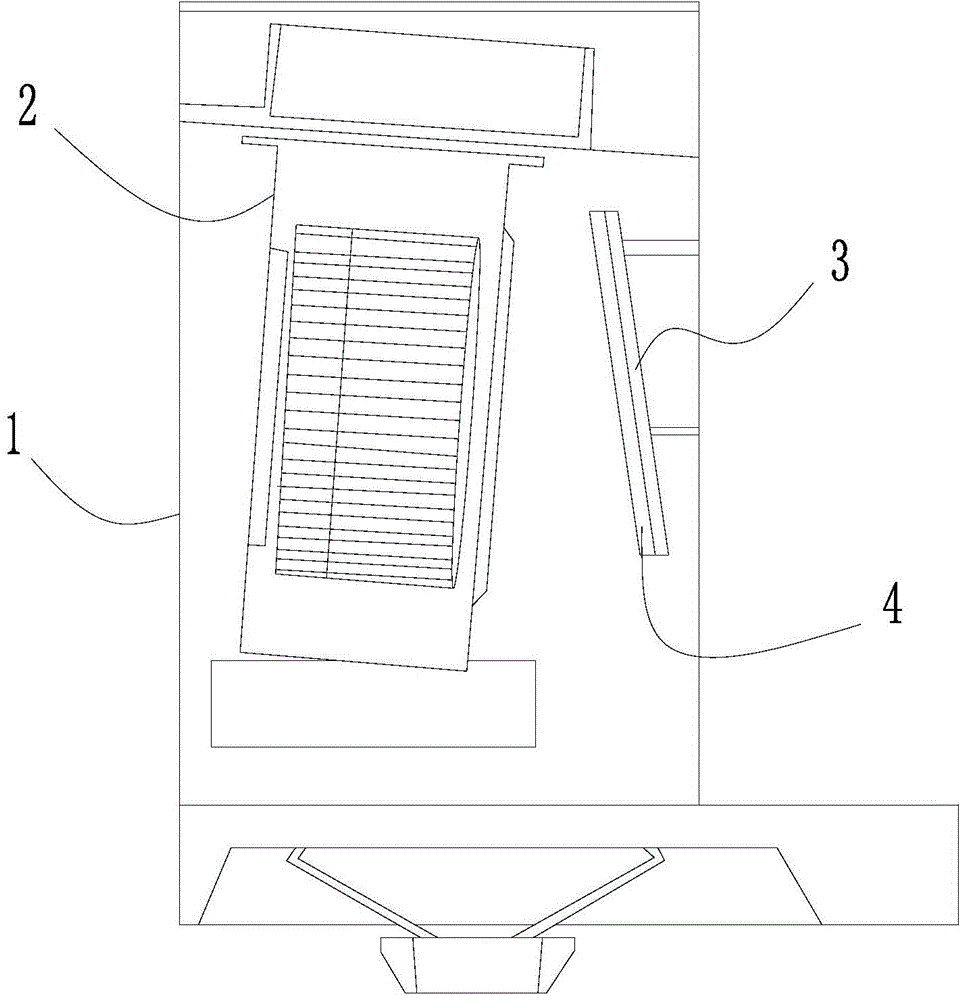

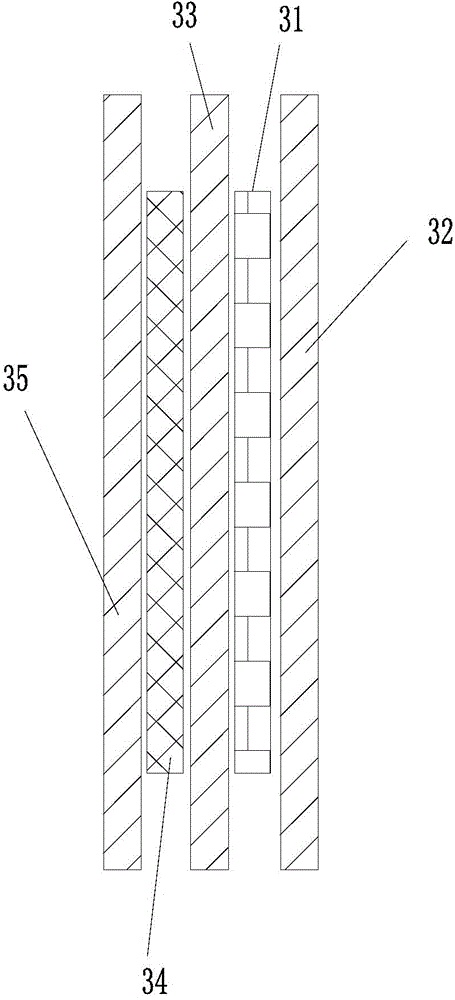

[0017] Such as figure 1 figure 2 As shown, a range hood that can be silenced includes a casing 1 and a volute 2, the volute 2 is arranged inside the casing 1, the lower end of the casing 1 is provided with an inlet, the upper end of the casing 1 is provided with an outlet, and the inside of the volute 2 A motor and an impeller are provided, the side end of the volute 2 is provided with an air inlet, the upper end of the volute 2 is provided with an air outlet, the air outlet communicates with the outlet of the casing 1, and the inner wall of the casing 1 opposite to the air inlet of the volute 2 is provided with The sound-absorbing plate 4; the volute 2 is arranged obliquely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com