Method for qualitative and quantitative analysis of titanium dioxide or/and zinc oxide nanoparticles in cosmetic

A zinc oxide nano, titanium dioxide technology, applied in particle size analysis, material analysis, particle and sedimentation analysis, etc., can solve the problems of cumbersome operation, time-consuming, poor recovery rate, etc., and achieve the effect of optimizing treatment conditions and the method is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1 Sample pretreatment solvent selection

[0089] 1. Extraction of nanoparticles in cosmetics

[0090] Different analytical instruments have certain requirements for the preparation of samples. Since cosmetics are mainly composed of organic matter and contain less inorganic nanoparticles, it is not possible to directly dry the cosmetics as they are and make them into powders for characterization and analysis of nanostructures. Combined with the sample preparation requirements of TEM, XRD, XPS and other characterization techniques, it is necessary to remove most of the organic matter in the cosmetics, and try not to lose the titanium dioxide or zinc oxide nanoparticles in the cosmetics.

[0091] The densities of nano titanium dioxide and zinc oxide are 3.8-4.3g / cm 3 and 5.6g / cm 3 , After adding an organic solvent and ultrasonically centrifuging, the organic matter is dissolved in the supernatant, and the nanoparticles are precipitated at the bottom, thereby re...

Embodiment 2

[0116] Qualitative and quantitative analysis of embodiment 2 titanium dioxide nanoparticles

[0117] 1. Qualitative and semi-quantitative analysis

[0118] 1. Sample preparation

[0119] S1. Sample number: 7 different brands of sunscreen and whitening products on the market are numbered 1-7, which are: sunscreen No. 1-3, liquid foundation No. 4-6, and pressed powder No. 7.

[0120] S2. Weigh about 0.3mg of the sample into a 10mL centrifuge tube, add 9mL of ethanol and let it stand for 2h to break the emulsification, ultrasonicate at 135w, 40kHZ for 5min, centrifuge at 10000r / min for 5min, and leave the precipitate;

[0121] S3. Add 9 mL of ethyl acetate to the precipitate obtained in S2, sonicate at 135w, 40kHZ for 5min, centrifuge at 10000r / min for 5min, remove most of the organic components and leave the precipitate; add 9mL of ethyl acetate again, and treat with 135w, 40kHZ for 5min , centrifuge at 10000r / min for 5min, and keep the precipitate;

[0122] S4. Finally, dr...

Embodiment 3

[0157] Qualitative and quantitative analysis of nano zinc oxide in the embodiment 3 cosmetics

[0158] 1. Qualitative and semi-quantitative analysis

[0159] 1. Sample preparation

[0160] Two commercially available sunscreen and whitening products of different brands are numbered: Sunscreen No. 8 and No. 9, and the pretreatment method is the same as in Example 1.

[0161] 2, TEM, XRD, XPS analysis method is the same as embodiment 1.

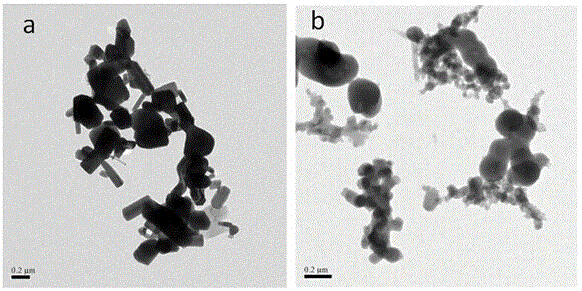

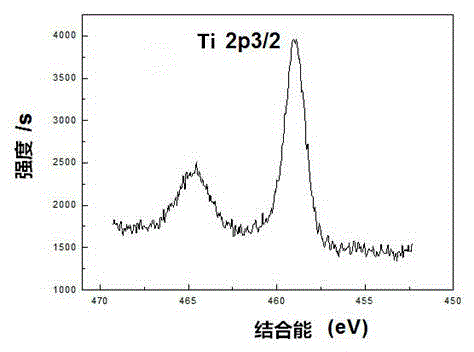

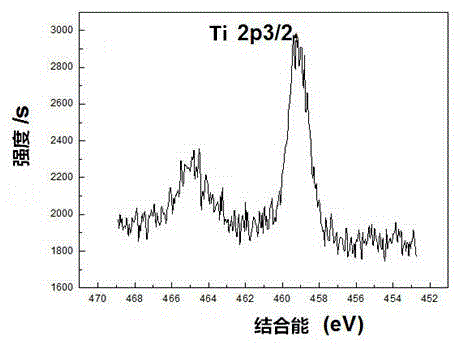

[0162] (1) Sample TEM characterization analysis results

[0163] The results are attached Figure 19 and 20 shown. The particles of No. 8 sunscreen have different shapes, including rod shape, round shape and other irregular shapes. The size range is between 6.5 nm and 88 nm, and the average size is 34.5 nm. The EDS spectrum shows that the main inorganic element is Zn.

[0164] Most of the particles of sunscreen No. 9 were round in shape, with a size range of 11.8 nm to 46.9 nm and an average size of 25.3 nm. EDS spectrum shows that the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap