Debris Containment System with Reduced Optical Component Thermal Distortion and High Transmission Efficiency

A technology of thermal deformation and high transmission, applied in the semiconductor field, can solve the problems of thermal deformation of the secondary mirror, affect the exposure quality, and instability of the light spot at the intermediate focus, and achieve the effects of reducing thermal deformation, improving transmission efficiency, and increasing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

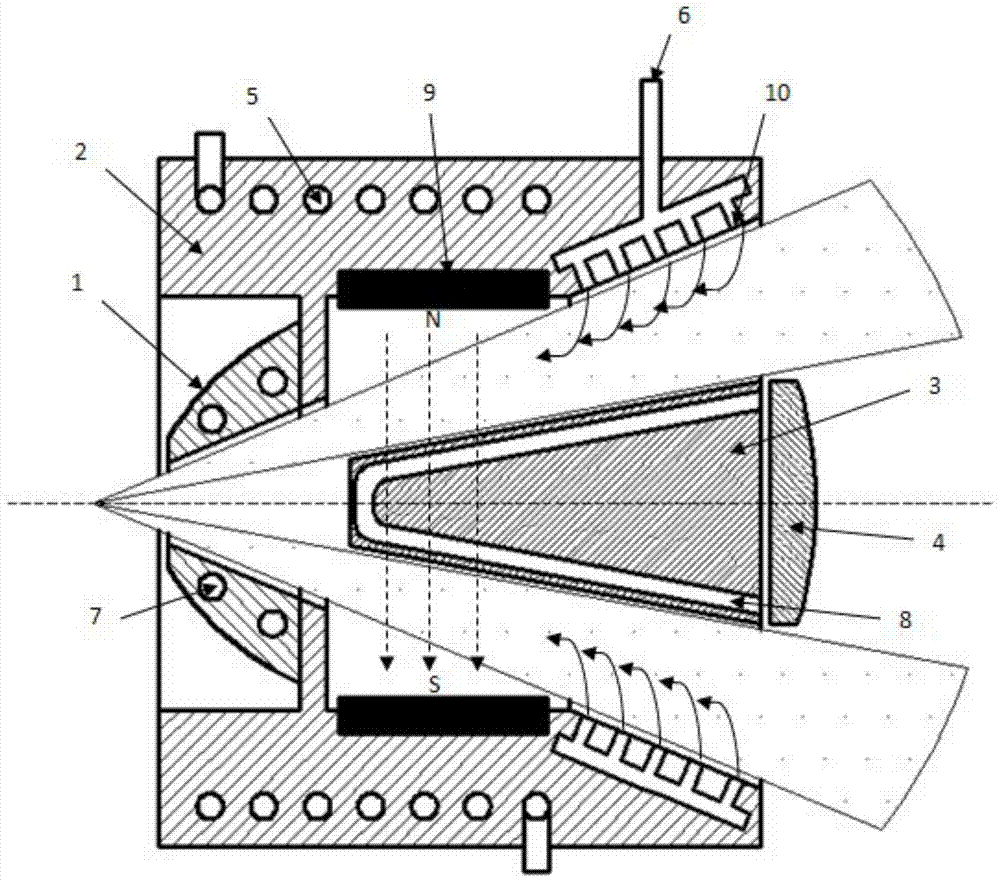

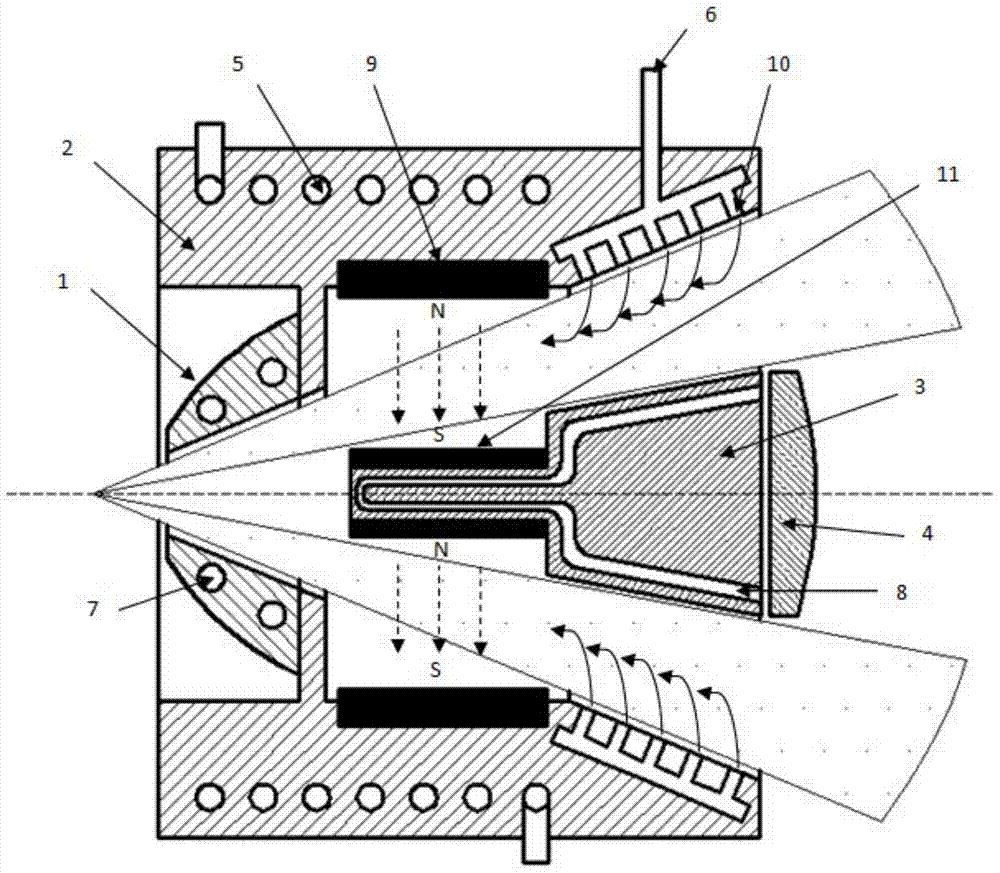

[0017] Such as figure 1 As shown, the debris suppression system with reduced thermal deformation of optical components and high transmission efficiency is mainly composed of debris blocking cover 1 , debris deflector 2 and radiation blocker 3 . When the light source generates EUV radiation, the electrode will lose, thus forming a large amount of debris, which includes neutral particles, charged particles and residual discharge gas, etc., which will affect the transmission efficiency of EUV and affect the optical components downstream of the beamline. Surfaces are heavily soiled and damaged.

[0018] The main function of the debris blocking cover 1 is to block most of the debris from entering the subsequent beamline without affecting the emission angle of the light source point. A coolant channel 7 is processed inside the debris blocking cover 1, and the tem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap