Radiator stamping part structure

A technology of stamping parts and heat sinks, which is applied in the field of heat sink stamping parts structure, can solve problems such as ineffective heat dissipation of heat sinks, poor materials of notebook heat sinks, and abnormal heat dissipation of computers, etc., achieving good use value and reasonable appearance design , the effect of high-efficiency radiator work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

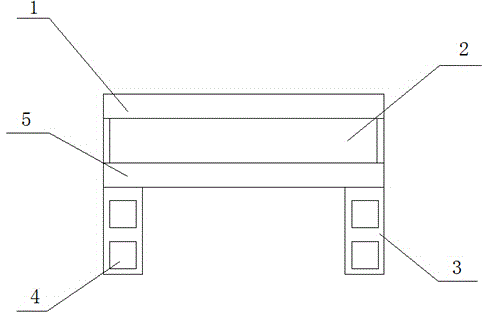

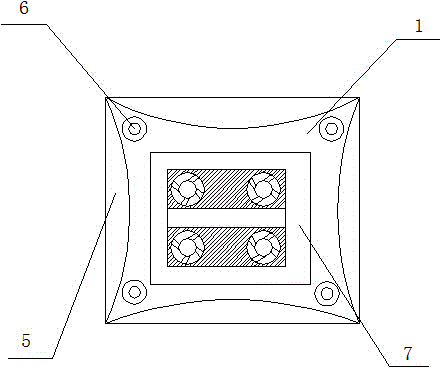

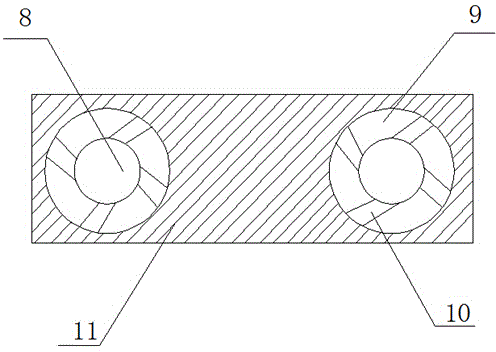

[0024] Example: such as Figure 1-3 As shown, a radiator stamping part structure of the present invention includes a ventilation plate 1, a heat dissipation belt 2, a tripod 3, a foot hole 4, a bottom plate 5, a bolt 6, a square hole 7, a motor slot 8, a ventilation hole 9, and a wind blade Slots 10 and cooling nets 11; a heat dissipation belt 2 is arranged between the ventilation plate 1 and the bottom plate 5, and a tripod 3 is installed at the bottom of the bottom plate 5; foot holes 4 are arranged on the surface of the tripod 3; inside the ventilation board 1 square hole 7, and the ventilation plate 1 is tightly connected with the base plate 5 by bolts 6; a cooling net 11 is installed inside the base plate 5, and a ventilation hole 9 is arranged inside the cooling net 11; a motor slot 8 is installed inside the ventilation hole 9; Wind vane slots 10 are installed around the motor slot 8 .

[0025] As a preferred technical solution of the present invention, the four sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com