Establishing method and application of two-dimensional prediction model of silicon content in hot metal in blast furnace

A prediction model, blast furnace molten iron technology, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] This embodiment adopts a steel plant 2650m 3 Based on the actual production data of the blast furnace, a two-dimensional prediction experiment of the silicon content in molten iron was carried out.

[0122] A method for constructing a two-dimensional prediction model for the silicon content of molten iron in a blast furnace, specifically comprising the following steps:

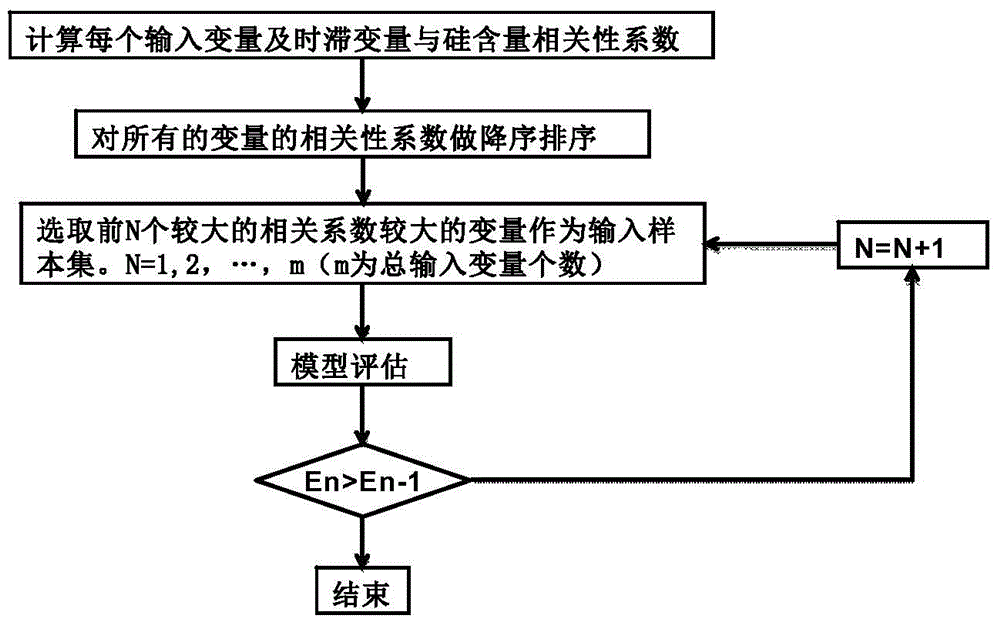

[0123] Collect 850 sets of data of the blast furnace from January 9, 2013 to February 19, 2013. According to the method of step S1, through the correlation analysis between the various variables and the silicon content of molten iron, the forward selection method is used to determine the correlation with the silicon content of molten iron. A strong and appropriate number of input variable data sample sets; the variable selection results are shown in Table 3 below, and a total of 10 variables are used as input variables for the two-dimensional silicon content prediction model. Then, the Mahalanobis dist...

Embodiment 2

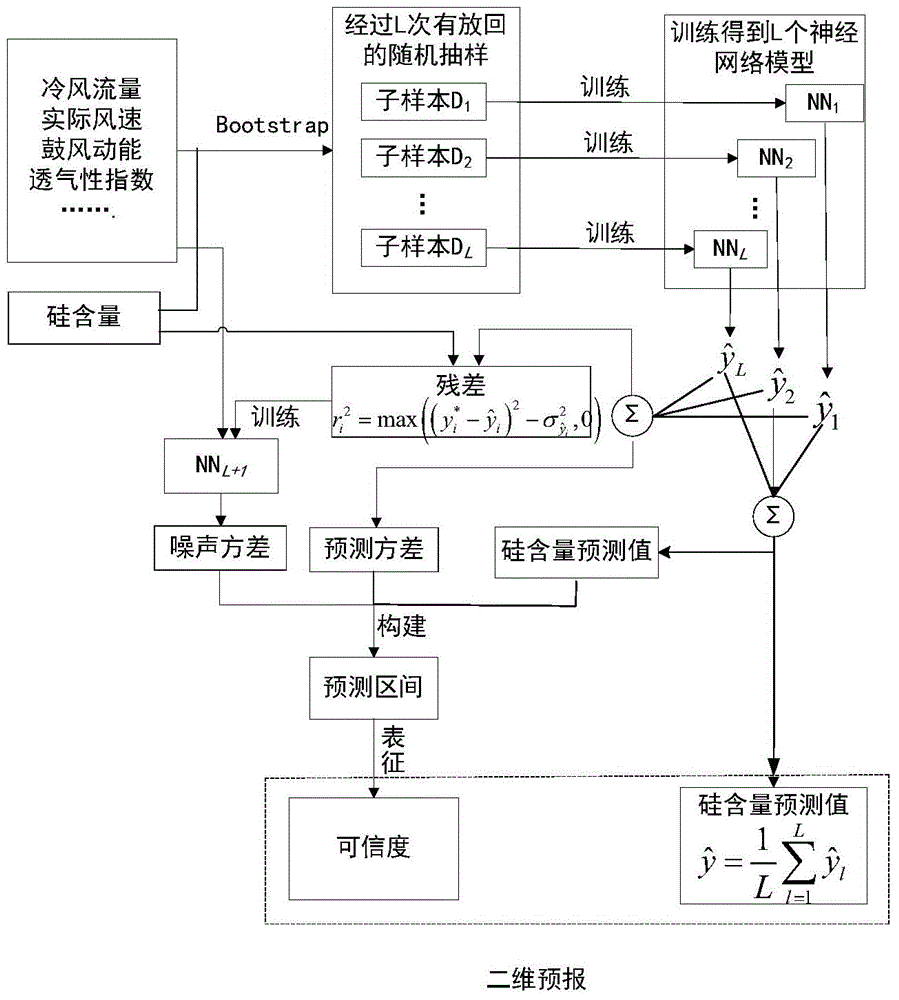

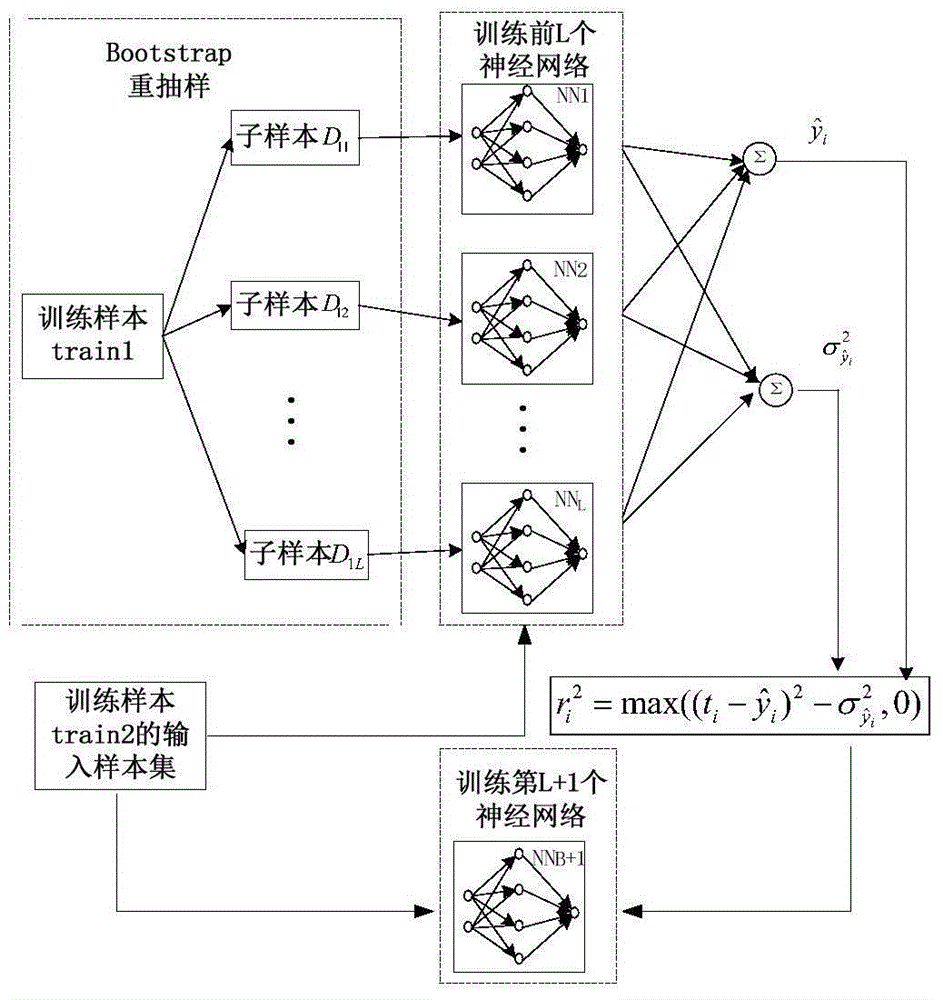

[0131] This embodiment relates to a two-dimensional prediction method for the silicon content of molten iron in blast furnace using the two-dimensional prediction model of silicon content in molten iron constructed in embodiment 1. Specifically, the sample set D in embodiment 1 is 3 Input the trained model as a test sample to get the point prediction value of silicon content prediction variance noise variance Then according to the formula (17), the final prediction interval is obtained; the prediction result is as follows Figure 4 As shown, the predicted value of the silicon content of the two-dimensional forecast model can well track the change of the measured value, especially in the case of large fluctuations in the actual value, the predicted value can basically maintain the same trend of change. Then, according to the formula (18), the credibility of the prediction results of different prediction interval width ranges is calculated, and the results are shown in Tabl...

Embodiment 3

[0136] This embodiment adopts a steel plant 2650m 3 Based on the actual production data of the blast furnace, a two-dimensional prediction experiment of the silicon content in molten iron was carried out.

[0137] A method for constructing a two-dimensional prediction model for the silicon content of molten iron in a blast furnace, specifically comprising the following steps:

[0138] Collect 1,150 sets of data of the blast furnace from March 2, 2015 to March 30, according to the method of step S1, through the analysis of the correlation between the various variables and the silicon content of molten iron, and use the forward selection method to determine the correlation with the silicon content of molten iron A strong and appropriate number of input variable data sample sets; the variable selection results are shown in Table 3 in Example 1, and a total of 10 variables are used as input variables for the two-dimensional silicon content prediction model. Then, the Mahalanobis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com