Method for determining steam system optimization scheduling feasible solution of iron and steel enterprises

A steam system and optimized scheduling technology, applied in the direction of manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as complex methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

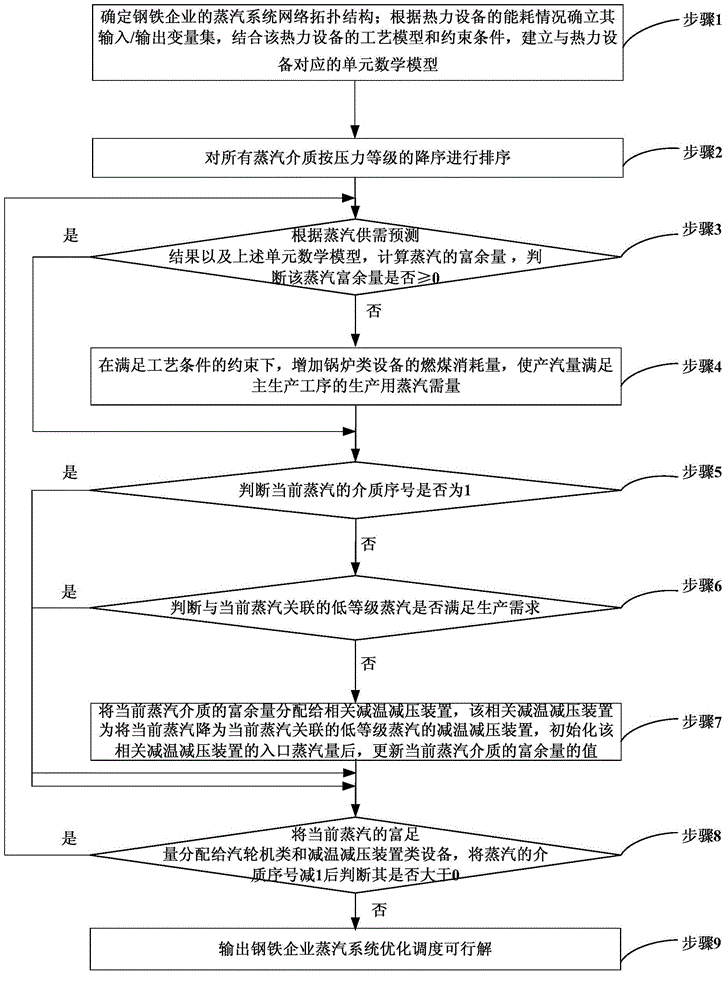

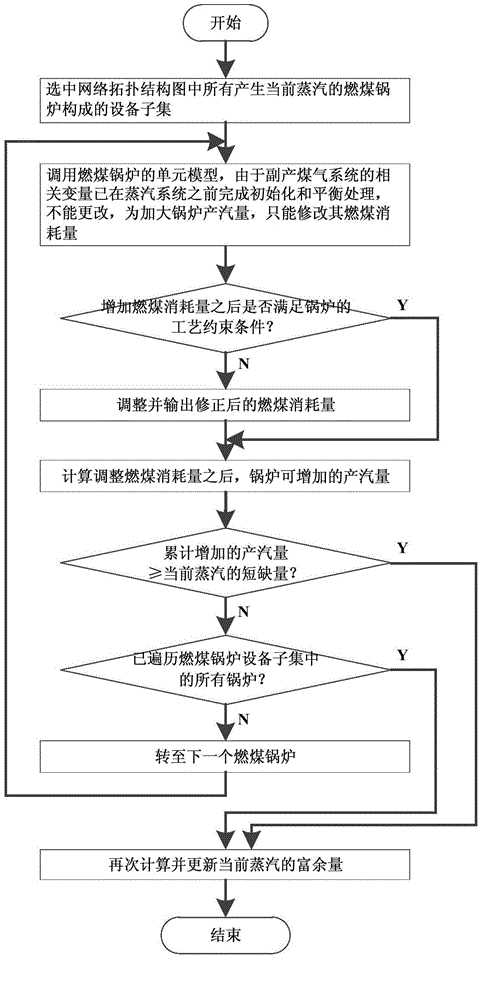

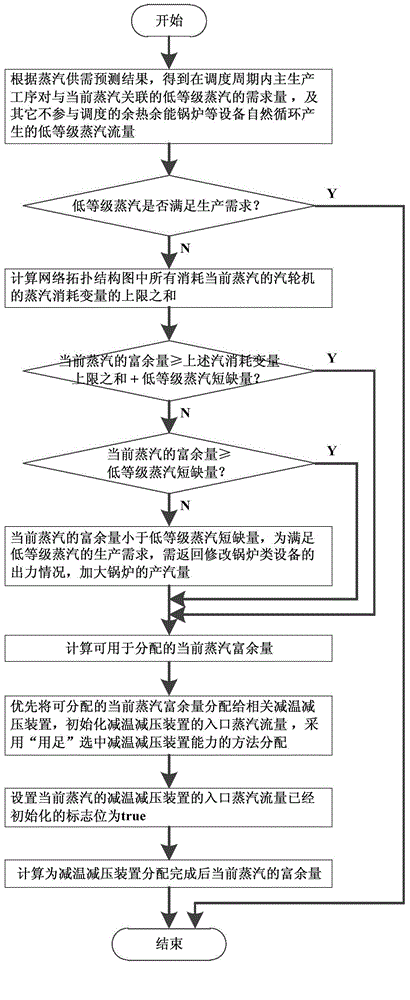

Method used

Image

Examples

Embodiment 1

[0153] Embodiment 1 provided by the present invention is a specific application embodiment of a method for determining a feasible solution for optimal scheduling of a steam system in an iron and steel enterprise provided by the present invention. Taking the Ganxin Iron and Steel 2 million tons project in Kezhou, Xinjiang as the research case of the embodiment of the present invention, Figure 5 It is a schematic diagram of the network topology of the iron and steel enterprise's energy system, and searches for a feasible solution to the optimal scheduling problem of its steam system. The gas system contains two by-product gas media, blast furnace gas and converter gas, as well as high-speed mixed gas. In addition, since converter gas needs to be used after pressurization, converter gas and pressurized converter gas are regarded as two different media. . The steam system includes two quality grades of medium-pressure steam and low-pressure steam, and the physical parameters suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com