Transformer heat dissipation device to which inner fins and telescopic outer fins are fixedly connected

A technology of outer fins and inner fins, which is applied in the field of transformer radiators, can solve problems such as poor heat dissipation of transformer radiators, and achieve good shock isolation effects, improved heat dissipation effects, and good heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

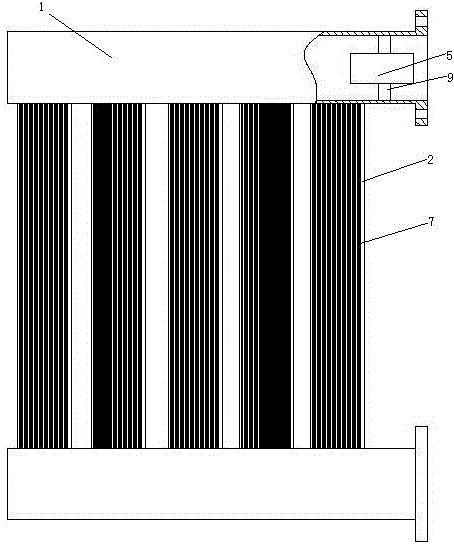

[0035] Embodiment one, see figure 1 , a transformer radiator fixedly connected with inner fins and retractable outer fins, comprising two oil pipes 1 and a plurality of cooling fins 2 connected between the two oil pipes. The two oil pipes 1 are distributed up and down and extend horizontally. A circulation pump 5 is arranged in the upper oil pipe of the oil pipe 1 . The circulation pump 5 is suspended in the oil pipe 1 through four vibration isolation blocks 9 . A plurality of outer fins 7 are arranged outside the heat sink 2 .

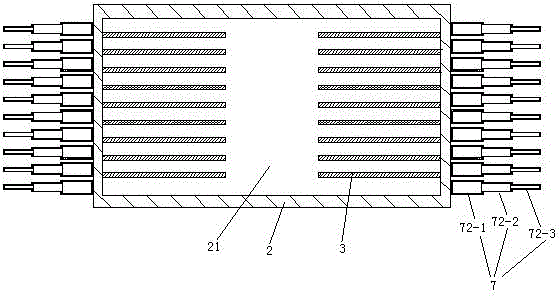

[0036] see figure 2 , The heat sink 2 is provided with a flow channel 21 . Runner 21 connects two oil pipes 1 (see figure 1 ) connectivity. Several inner fins 3 are arranged in the flow channel 21 . The inner fins 3 are connected together with the cooling fins 2 in an integral structure. The outer fins 7 include three cooling plates. The three cooling plates are distributed as the innermost cooling plate 72-3, the middle cooling plate 72-2 a...

Embodiment 2

[0048] Embodiment two, the difference with embodiment one is:

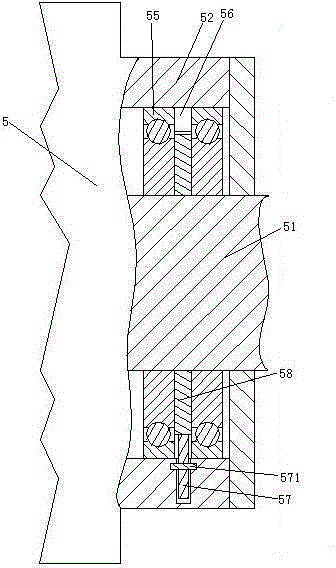

[0049] see Figure 10 , the pump shaft 51 is pierced with a circular inner rod 511 . The inner rod 511 is a tubular structure. The inner surface of the pump shaft 51 is provided with an inner friction layer 512 . The inner rod 511 includes a left rod 5111 and a right rod 5112 . The outer peripheral surfaces of the left rod 5111 and the right rod 5112 are provided with an outer friction layer 5113 . The outer friction layer 5113 covers the inner rod 511 along the circumference of the inner rod 511 . The left end of the left rod 5111 is connected with the pump shaft 51 through the left energy-absorbing spring 513 . The right end surface of the left rod 5111 is provided with a plurality of first reversing teeth 5114 distributed along the circumferential direction of the left rod. The right end of the right rod 5112 is connected with the pump shaft 51 through the right energy-absorbing spring 514 . The left end...

Embodiment 3

[0051] Embodiment three, the difference with embodiment two is:

[0052] see Figure 11 , The heat sink 2 is provided with a number of connecting pipes 22 communicating with the flow channel 21 . The oil pipe 1 is provided with several oil holes 11 . The outer end of the oil hole 11 is connected with a pipe seat 12 . The pipe base 12 and the oil pipe 1 are welded together. The inner pipe 4 is pierced in the oil hole 11 . The inner end of the inner tube 4 is provided with a flange 41 . The inner tubes 4 pass through the tube bases 12 and penetrate into the connecting tubes 22 one by one to realize the communication between the oil tube 1 and the flow channel 21 in the cooling fin 2 .

[0053] see Figure 12 , The flange 41 is hooked on the inner peripheral surface of the oil pipe 1 . The flange 41 and the inner peripheral surface of the oil pipe 1 are only connected together by abutting. The junctions of the pipe base 12 , the inner pipe 4 and the connecting pipe 22 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com