Graphene amino resin preparation method and device

An alkenyl amino and resin technology, applied in the field of graphene amino resin preparation, can solve the problems of unstable combination of graphene and amino resin, inability to prevent large particles from entering the container, poor seismic isolation effect, etc., and achieve good seismic isolation effect. , Combination stability, high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

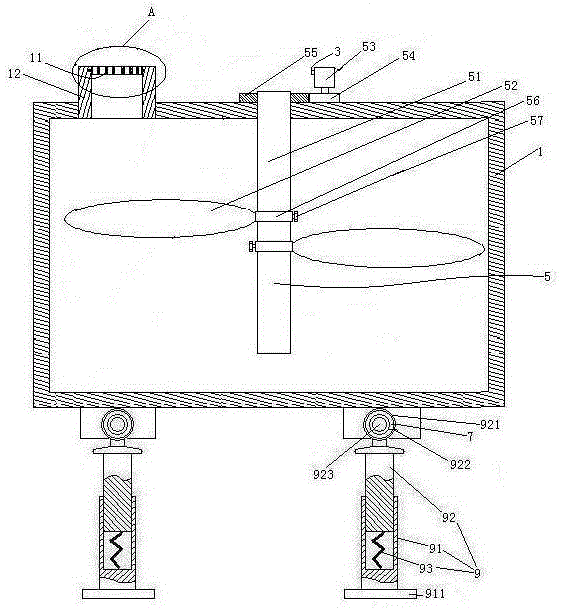

[0051] Embodiment one, see figure 1 , a graphene amino resin preparation equipment, comprising a container 1 and a stirrer 5.

[0052] The container 1 is provided with a feed opening 12 . Feed port 12 filter plate 11.

[0053] The agitator 5 includes a rotating shaft 51 , a stirring blade 52 , a motor 53 , a driving gear 54 and a driven gear 55 . The rotating shaft 51 is input into the container 1 . The rotating shaft 51 is rotatably connected to the container 1 . The rotating shaft 51 extends in the vertical direction. The stirring blade 52 is connected to the part of the rotating shaft 51 located in the container. The stirring blade 52 is a blade structure. The driven gear 55 is fixed on the upper end of the rotating shaft 51, and the driven gear 55 and the rotating shaft 51 are coaxial. The driving gear 54 is disposed on the power output shaft of the motor 53 . The driving gear 54 meshes with the driven gear 55 together. Each stirring blade 52 is respectively provi...

Embodiment 2

[0064] Embodiment two, the difference with embodiment one is the change of graphene amino resin preparation equipment structure, concrete change is:

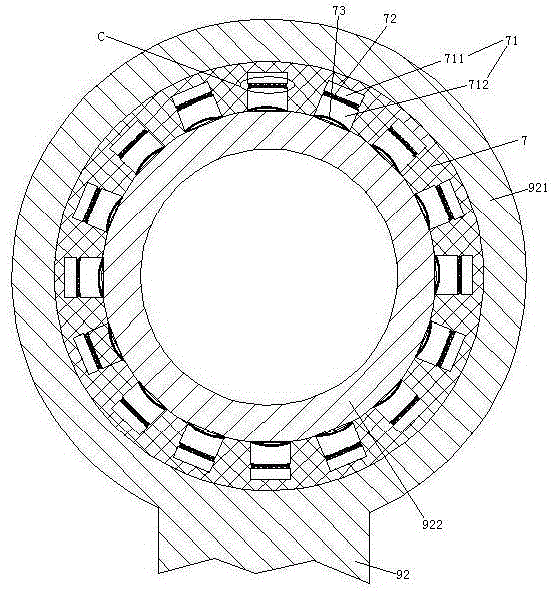

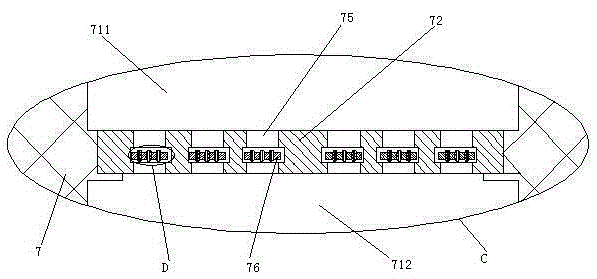

[0065] see Figure 7, The shock-isolation foot 9 is also provided with a driving mechanism 6 . The inner ring 922 is rotatably connected to the rubber ring 7 , and the rubber ring 7 is fixedly connected with the connecting ring 921 .

[0066] The drive mechanism 6 includes a ratchet 61 , a pawl 62 for driving the ratchet, and a drive rod 63 . The ratchet 61 is coaxially connected with the inner ring 922 . The ratchet 61 is integrated with the inner ring 922 . The pawl 62 is fixedly connected to one end of the driving rod 63 . The upper section 92 is provided with a sliding hole 924 . The other end of the driving rod 63 can slide through the sliding hole 924 two-dimensionally. The lower end of the drive rod 63 is slidably hooked to the lower section 91 along the radial direction of the connecting ring 921 (see figure 1 ) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com