A kind of stabilizer of pesticide granule and its application

A stabilizer and granule technology, applied in the field of pesticides, can solve the problems of stabilizer failure, affecting the quality and effect of "medicine fertilizer", poor effect performance, etc., and achieve the effect of solving the problem of unstable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

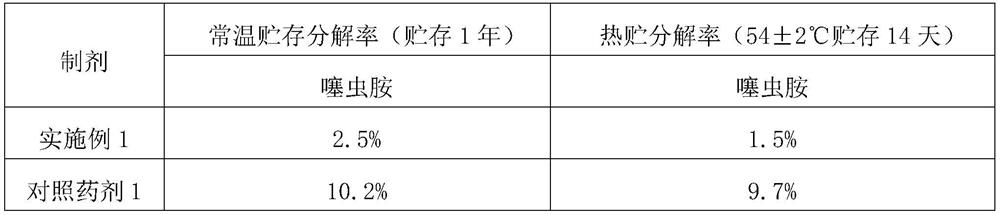

[0023] Example 1: 1% clothianidin granules

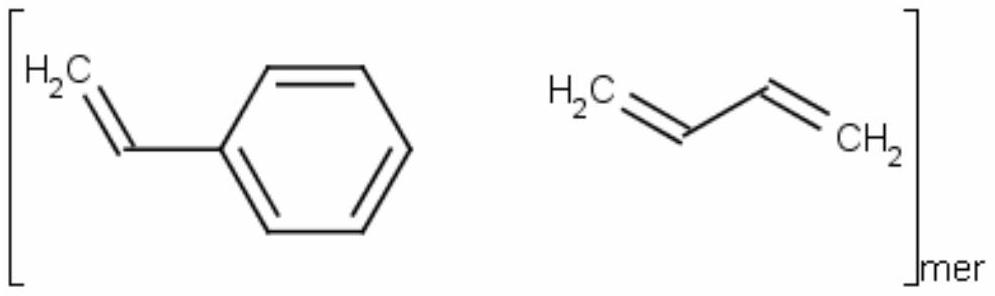

[0024] First prepare 30% clothianidin oil intermediate: mix 29.07 g of methyl ester oil, 30.00 g of hydrogenated styrene butadiene copolymer (SEBS), and 10.00 g of OF-7812, after dispersing and mixing evenly, then add 97% clothianidin 30.93 g of amine was dispersed at a high speed for 20-30 minutes to obtain a homogeneous oil phase system, and a 30% clothianidin oil intermediate was obtained.

[0025] Using granular urea as a fertilizer carrier, 92.67 grams of granular urea was placed in a drum stirring device, and stirring was started, and 3.33 g of 30% clothianidin oil intermediate was weighed into the urea carrier, stirred for 3 minutes, until the oil intermediate was completely uniformly dispersed, adding Add 4.00 g of anti-caking powder, stir for 2 minutes, until the anti-caking powder is uniformly dispersed in the carrier, and the preparation of the 1% clothianidin granule sample is completed. The rotating speed of the stirri...

Embodiment 2

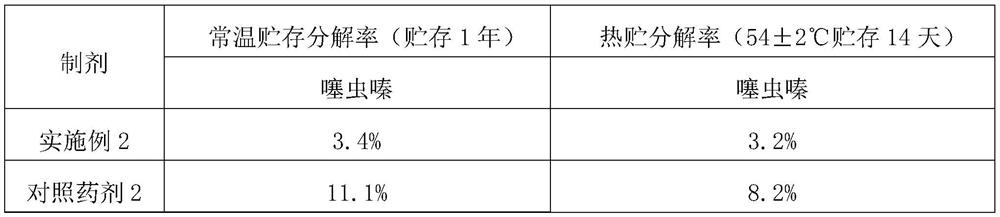

[0036] Example 2: 0.12% thiamethoxam granules

[0037] First prepare 5% thiamethoxam oil intermediate: mix 54.79 g of methyl ester oil, 30.00 g of hydrogenated styrene butadiene copolymer (SEBS), and 10.00 g of OF-7812, disperse and mix evenly, then add 96% thiamethoxam 5.21 g of thiamethoxam was dispersed at a high speed for 20-30 minutes to obtain a homogeneous oil phase system, and a 5% thiamethoxam oil intermediate was obtained.

[0038] Using granular urea as a fertilizer carrier, 93.6 grams of granular urea was placed in a drum stirring device, and stirring was started, and 2.40 g of a 5% thiamethoxam oil intermediate was weighed into the urea carrier, and stirred for 3 minutes until the oil intermediate was uniformly dispersed on the carrier. , add 4.00 g of anti-caking powder, stir for 2 minutes, until the anti-caking powder is uniformly dispersed in the carrier, and the 1% thiamethoxam granule sample preparation is completed. The rotating speed of the stirring equipm...

Embodiment 3

[0049] Embodiment 3: 6% metaldehyde carbaryl granules

[0050] First prepare 36% Metaldehyde carbaryl oil intermediate: mix 27.90 grams of white oil 7#, 30 grams of hydrogenated styrene-butadiene copolymer (SEBS), and 5.00 grams of NP-10, and mix evenly through dispersion. Then add 27.60 grams of metaldehyde and 9.50 grams of carbaryl, and disperse at a high speed for 20 to 30 minutes to obtain a homogeneous oil phase system and obtain a 36% metaldehyde·carbaryl oil intermediate.

[0051] With the organic-inorganic compound fertilizer as the carrier, 73.33 grams of the organic-inorganic compound fertilizer was placed in the drum stirring device, and the stirring was started, and 16.67 g of 36% metaldehyde carbaryl oil intermediate was weighed on the fertilizer carrier, and stirred for 3 minutes until The oil intermediate is uniformly dispersed on the carrier, 10.0 g of anti-caking powder is added, and stirred for 2 minutes until the anti-caking powder is evenly dispersed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com