Preparation method for nickel-based abrasion-resistant cladding layer

A cladding layer, nickel-based technology, applied in the direction of coating, metal material coating process, etc., can solve problems such as workpiece surface wear, achieve the effect of improving hardness, good interface bonding performance, and solving unstable interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

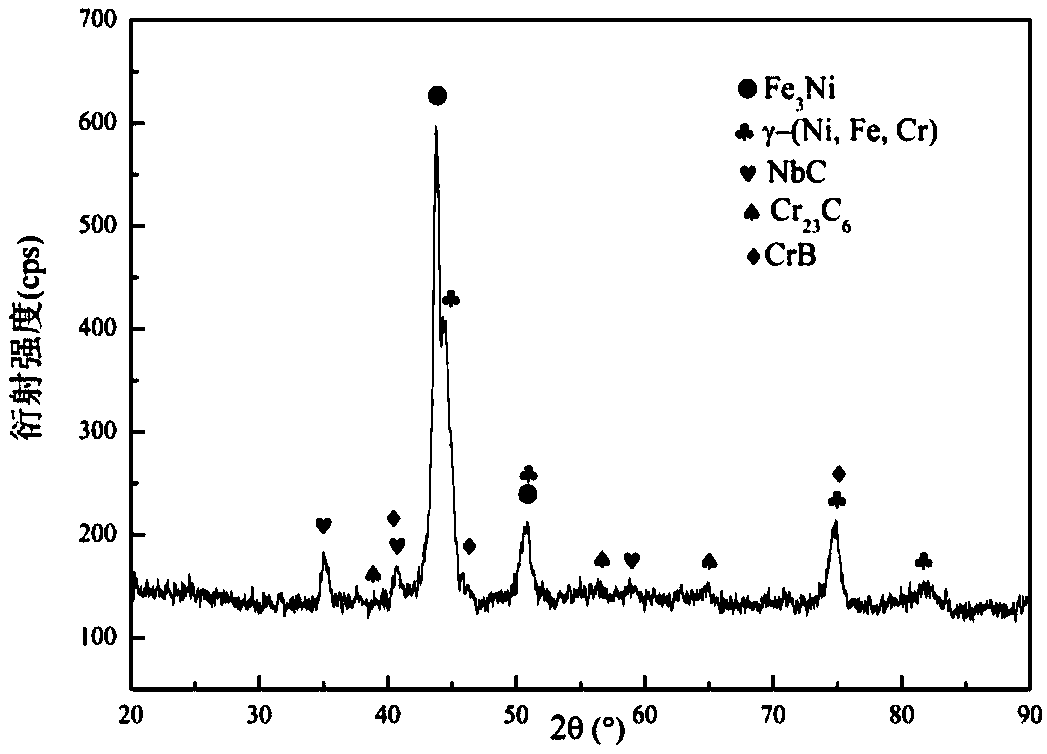

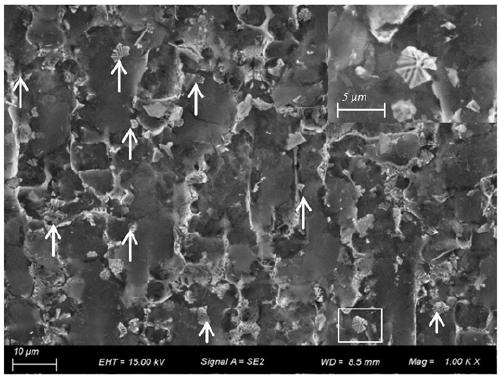

[0035] In Example 1, NiCrBSi powder and elemental Nb powder are mixed according to the mass ratio of 94:6, wherein the particle size of NiCrBSi powder is 25-50 μm, the composition is shown in Table 1, and the purity of Ni, Cr, C, and Fe is 99%. , B. The purity of Si is 99.99%; the powder particle size of elemental Nb powder is 30-70 μm, and the purity is 99.99%. After uniform mechanical mixing, the cladding powder is obtained.

[0036] Table 1 NiCrBSi powder composition

[0037]

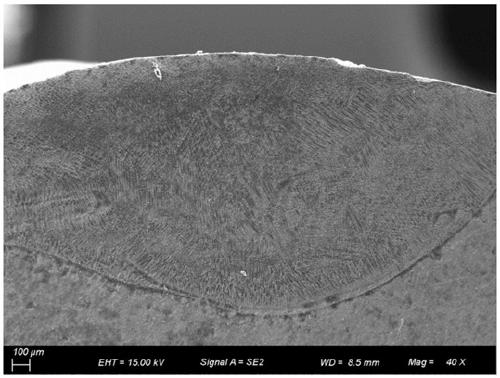

[0038] The main steps include: quenching and tempering 45 steel→surface grinding and degreasing treatment→preparing binder→mixing mixed powder and binder and coating on the surface of the substrate to obtain a prefabricated layer→argon tungsten argon tungsten on the prefabricated layer Arc cladding treatment to prepare Ni-based cladding layer.

[0039] Preparation of Ni-based cladding layer

[0040] The first step, powder preparation

[0041] Weigh 94g of NiCrBSi powder and 6g of Nb powder and...

Embodiment 2

[0060] In Example 2, NiCrBSi powder and Nb powder were used for powder preparation. The powder components of NiCrBSi powder and Nb powder remained unchanged, and only the mass ratio of the two powders was changed to 96:4. 96g of NiCrBSi powder and 4g of Nb powder were weighed and mixed by ball milling to prepare mixed powder for cladding. All the other steps are the same as in Example 1. The performance of the obtained cladding layer is close to that of Example 1.

Embodiment 3

[0062] In this embodiment 3, the powder composition described in embodiment 1 is adopted, and the mass ratio of NiCrBSi powder and Nb powder is 94:6, and the tungsten argon arc cladding current and scanning speed are adjusted, and the adjusted cladding process parameters are shown in the table 3 shown

[0063] Table 3 Tungsten argon arc cladding process parameter list

[0064]

[0065] All the other steps are the same as in Example 1. The performance of the obtained cladding layer is close to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com