Combiner box and door thereof

A technology of combiner box and box door, which is applied to electrical components, photovoltaic modules, substation/distribution device casings, etc., can solve the problem of rusting bolts in the box, poor sealing effect of annular sealing strips, and rusting buttons of measuring boards, etc. problem, to achieve the effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

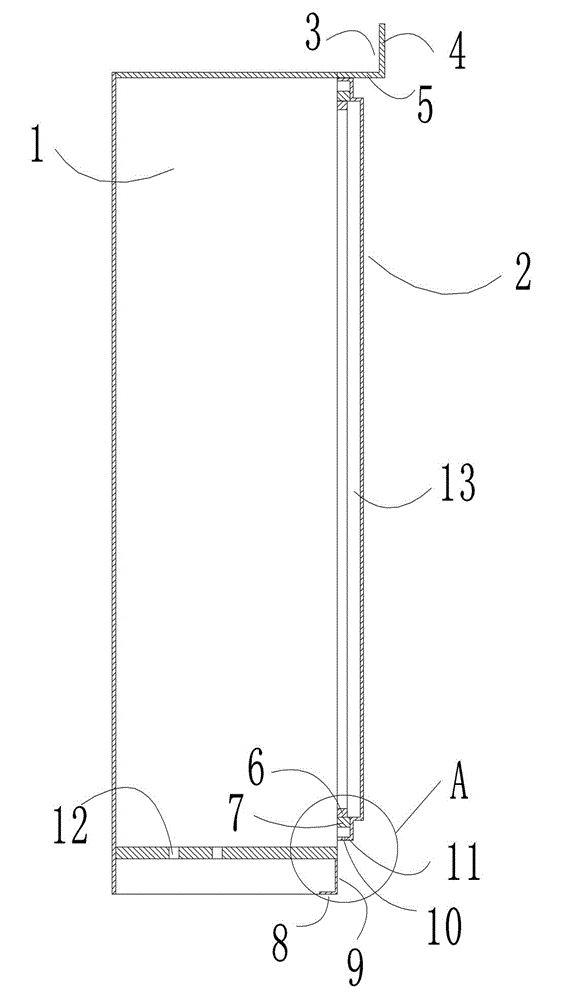

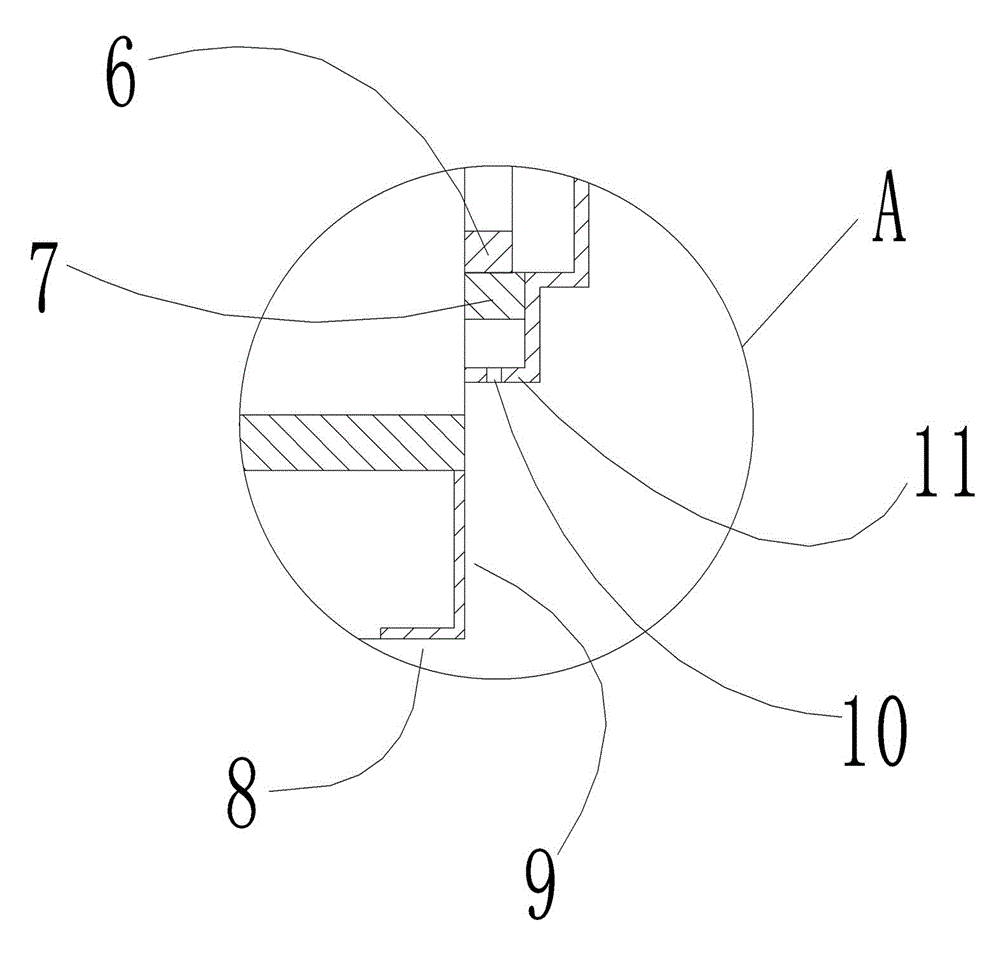

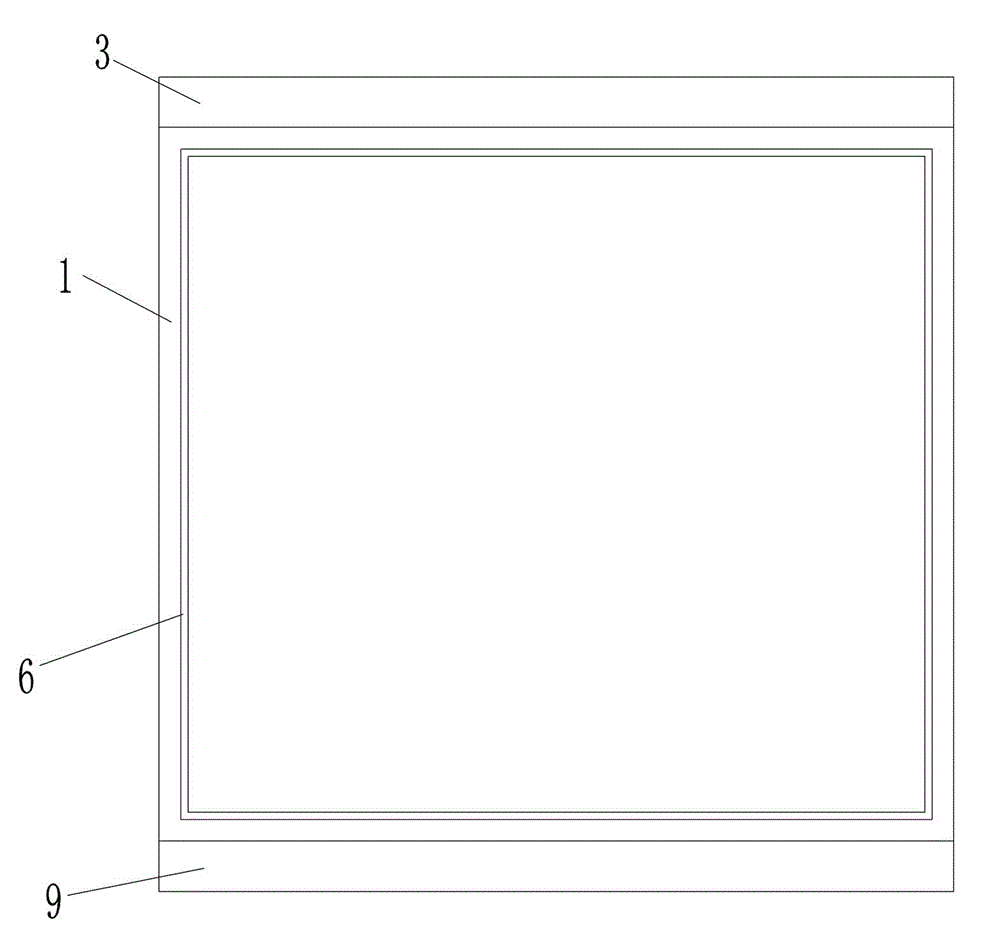

[0020] Examples of combiner boxes are Figure 1~3 As shown: it includes a casing 1 with an opening at the front end and a box door 2 arranged at the opening, and an annular sealing strip 7 is arranged around the periphery of the opening between the box door and the casing. In this embodiment, the annular sealing strip 7 is solid. Located on the box door 2, the box door 2 includes a box door body, and the box door body is provided with an annular inner flanging ring arranged on the periphery of the annular sealing strip. The annular inner flanging includes an upper top edge, a lower bottom edge 11 and a The left side and the right side 13 between the upper top edge and the lower bottom edge 11, wherein the upper top edge and the lower bottom edge are straight-edge structures whose extension direction is perpendicular to the up-down direction, and the lower bottom edge is arranged at intervals along the length direction There are a plurality of water leakage holes 10 running thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com